Car safety hammer with prestressing force

A vehicle safety and prestressing technology, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle components, etc., can solve problems such as people turning over on horseback, small glass, missing hammer, etc., to improve flexibility and adaptability, high The effect of breaking glass and increasing the effective usage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

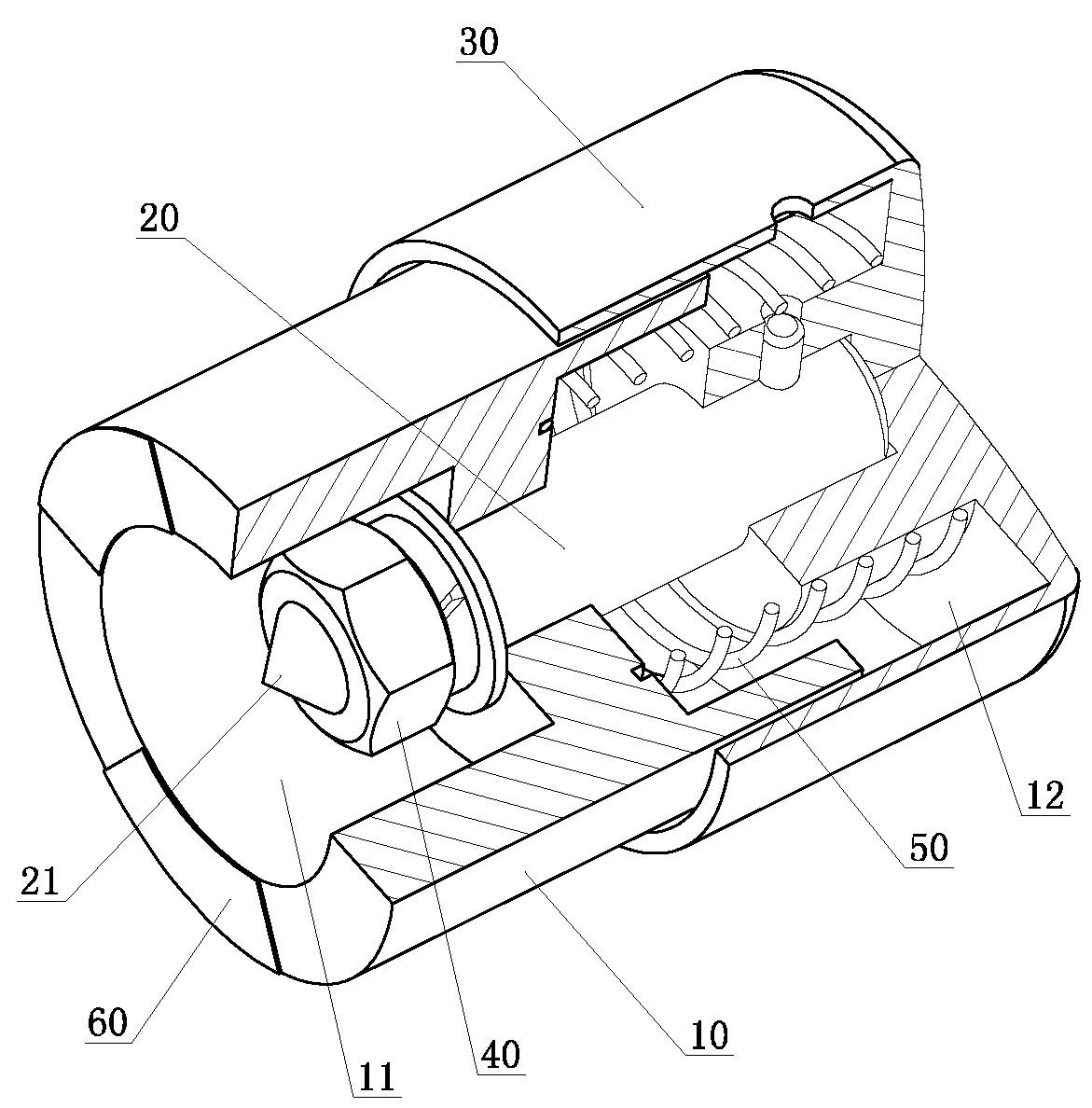

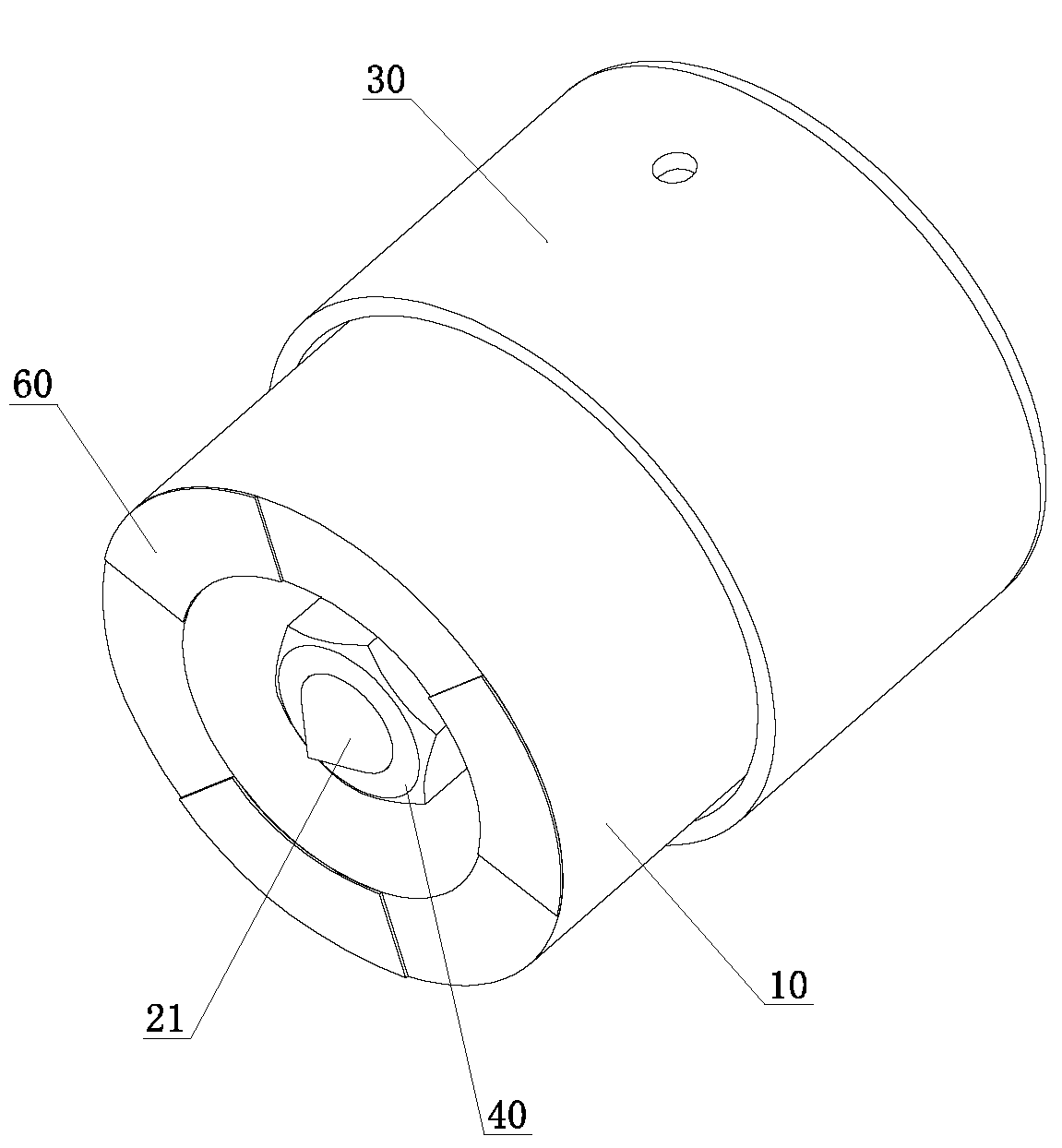

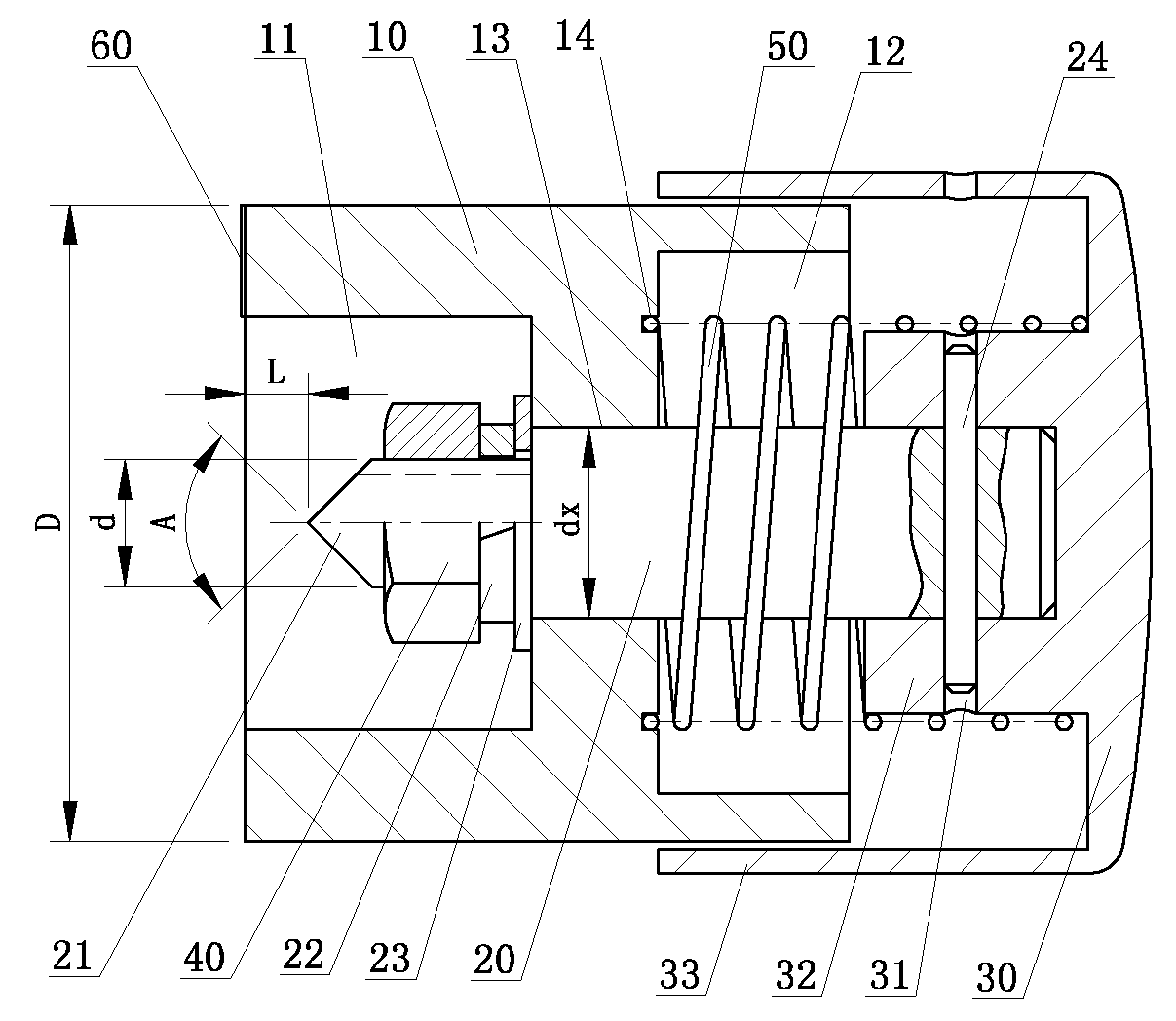

[0024] Such as figure 1 , figure 2 , image 3 , a car safety hammer with prestress, comprising a safety hammer body 10, a striker 20 and a clap button 30; wherein, the two ends of the safety hammer body are provided with a front chamber 11 and a front cavity which are separated by a partition wall and open outwards The rear cavity 12 is provided with a striker guide hole 13 on the partition wall; the striker is installed in the striker guide hole of the partition wall with a sliding fit, and the front part of the striker is located in the front cavity of the body, and its front end is a tapered tip 21. The pointed tip of the conical top is located at the position of the open end plane of the indented front cavity. The rear part of the striker is located in the rear cavity of the body and is fixedly connected with the beat button. On the striker, from the conical top to the partition wall There is a cylindrical stopper 40 as the rear striker in between, the stopper blocks th...

Embodiment 2

[0030] See Example 1 and figure 1 , figure 2 , image 3 , the shape of the safety hammer body can be a square column or a prism, and the material can be metal or non-metal. This embodiment is cylindrical with an outer diameter of D=40mm, and the striker guide hole is a round hole or a square hole (The square hole can place the firing pin to rotate), in this embodiment, a firing pin guide hole 13 with a diameter of dx=12mm is provided on the partition wall between the front cavity and the rear cavity; the material of the safety hammer body is aluminum alloy.

[0031] The striker is installed in the striker guide hole of the partition wall of the body with a sliding fit, a d=M8 connection thread with a boss is provided at the front end of the striker, and a taper A=90° is provided at the top of the M8 connection thread. The top of the firing pin is 21, the front end of the firing pin stretches into the front cavity of the body, and the rear end of the firing pin stretches int...

Embodiment 3

[0039] Such as Figure 5 , a prestressed automobile safety hammer, with the same structure as the embodiment 1 or 2 safety hammer body, striker, clap button, rear impact block and compression spring.

[0040] In this embodiment, the beat button shown is formed by plastic injection molding, and the striker is fixedly connected with the beat button when the beat button is injection molded.

[0041] The material of the body is plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com