Thin slurry mixture paved on thin-layer cover on ice and snow melting micro-surface and paving method

A thin slurry mixture and thin-layer covering technology is applied in the field of mixing asphalt at room temperature to achieve the effect of accelerating the promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

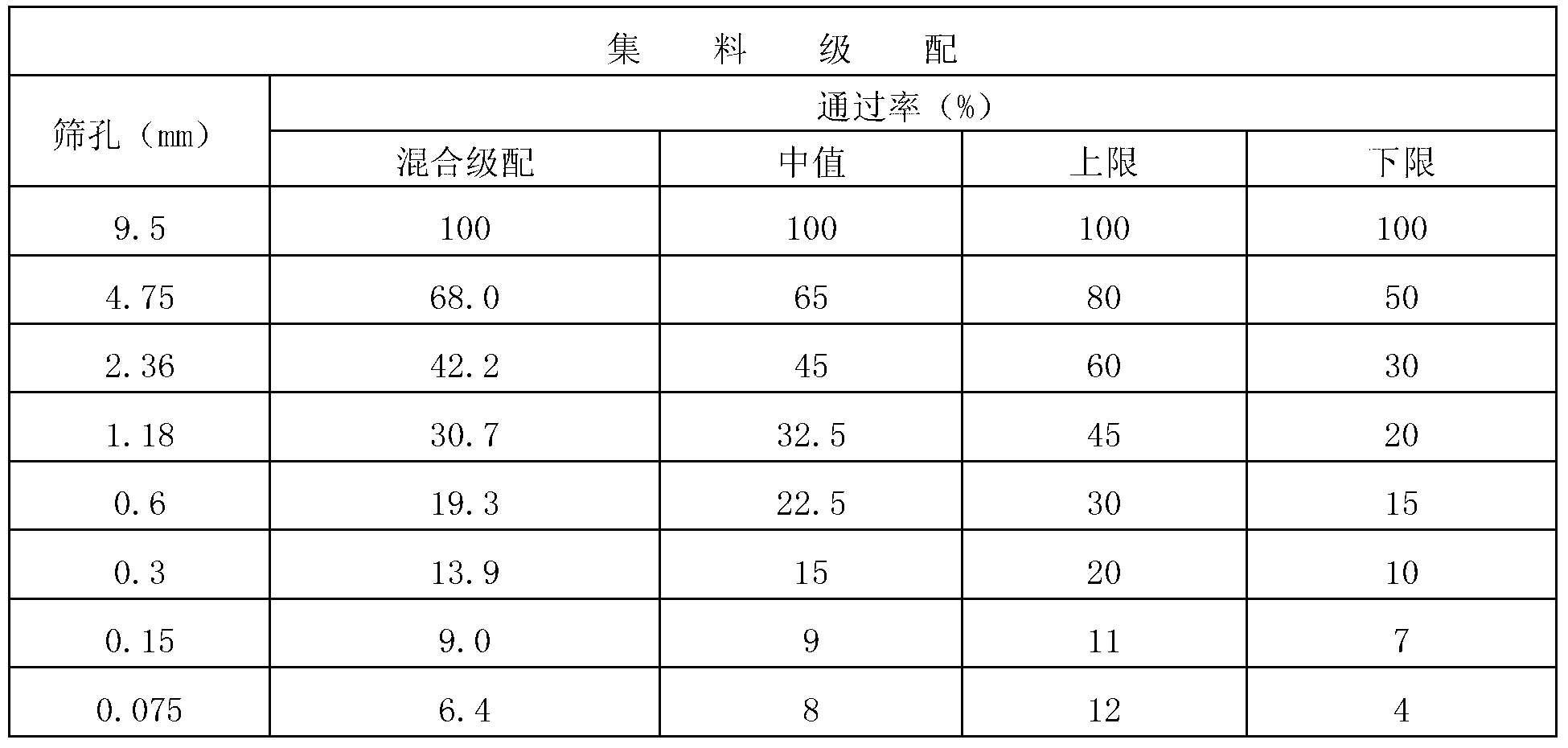

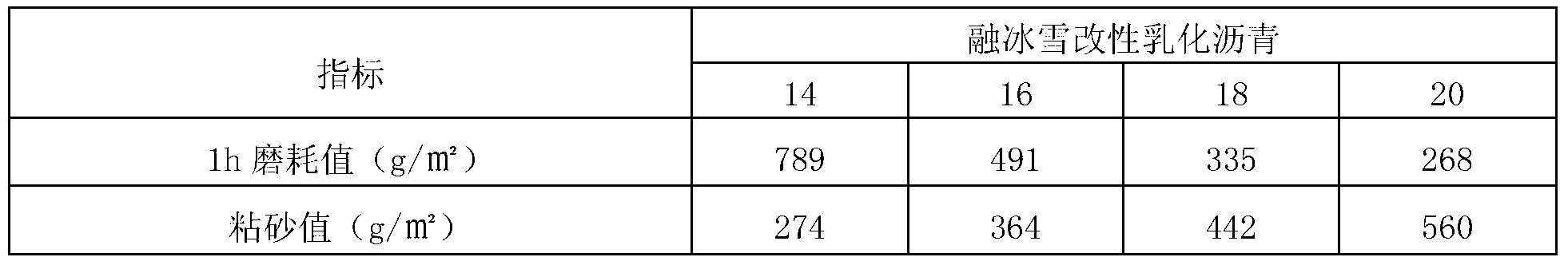

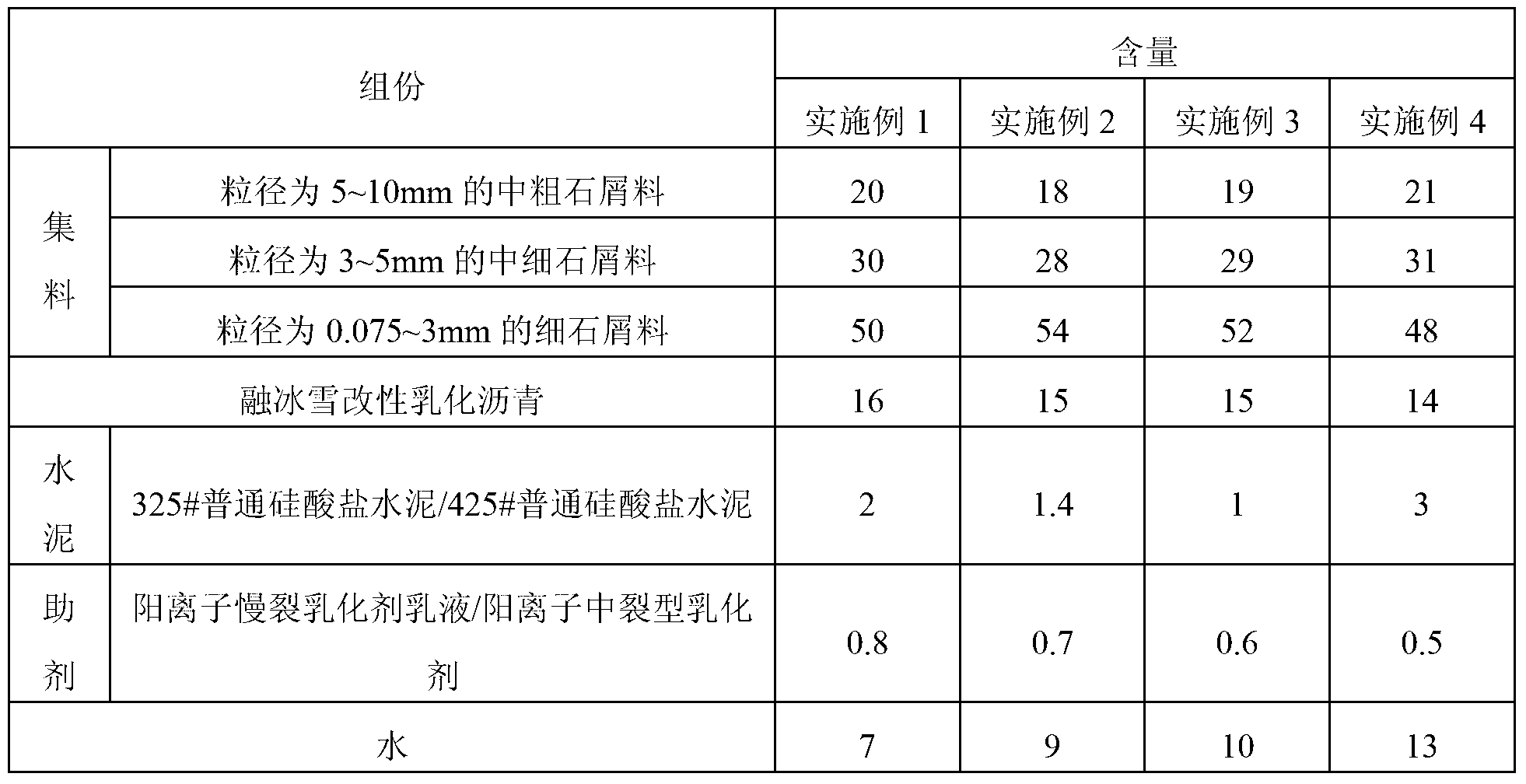

Examples

Embodiment Construction

[0044] Below in conjunction with example the present invention will be further described.

[0045] A laying method for laying a thin-layer overlay on the micro-surface of melting ice and snow. Compared with the existing construction method, no special modification of construction equipment is required. The key lies in the use of slurry mixture and the selection of the thickness of the overlay layer. Specifically For example, the method includes the following steps:

[0046](1) Test and evaluate the original pavement: test and evaluate the original pavement to ensure that the strength of the original pavement meets the structural bearing strength requirements;

[0047] (2) Repair and clean the original pavement: Reinforce and repair the road sections whose bearing strength of the original pavement structure does not meet the requirements, and re-inspect and evaluate; clean the surface of the road sections whose bearing strength of the original pavement structure meets the requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com