Flame retardant and smoke suppression type modified emulsified asphalt and preparation method and application thereof

An emulsified asphalt and smoke-suppressing technology, which is applied in the field of asphalt mixing at room temperature, can solve the problems of poor flame-retardant and smoke-suppressing effect, poor compatibility, and high cost, and achieve accelerated promotion and application, good compatibility, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Aluminum hydroxide used in the embodiment

[0039]

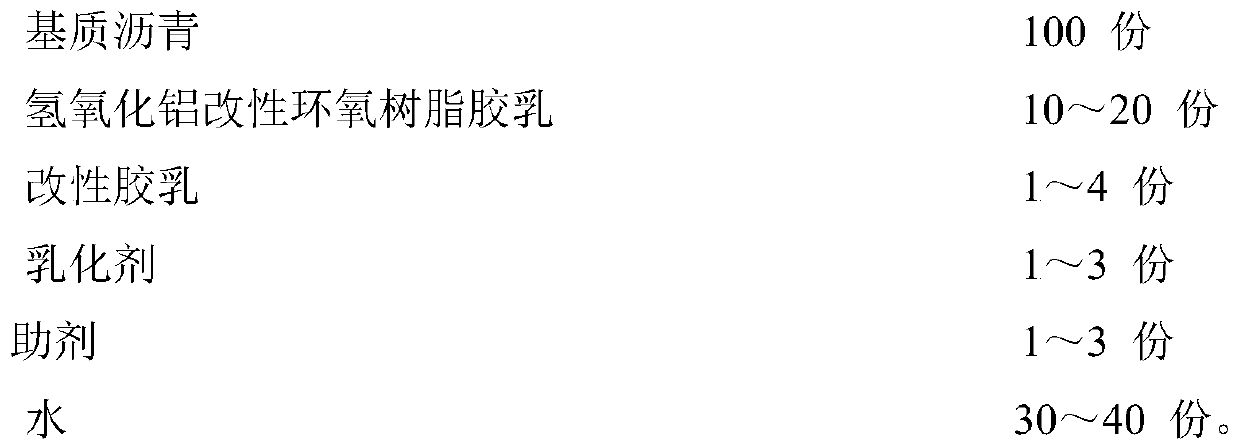

[0040] raw material:

[0041] 100 parts of road grade A matrix asphalt, 10 parts of aluminum hydroxide modified epoxy resin latex, 1 part of SBR modified latex (solid content 40%), 1 part of cationic mid-cracking emulsifier, inorganic aluminum hydroxide special surfactant (Span surfactant) 1 part, water 30 parts; aluminum hydroxide modified epoxy resin latex consists of 100 parts of epichlorohydrin, 100 parts of bisphenol A, and 1 part of aluminum hydroxide.

[0042] Preparation:

[0043] (1) detect aluminum hydroxide particle diameter;

[0044] (2) adopting aluminum hydroxide, epichlorohydrin and bisphenol A to carry out compounding, be mixed with aluminum hydroxide modified epoxy resin latex;

[0045] (3) Heat the base asphalt to 130°C 3 hours in advance;

[0046] (4) Inject the emulsifier into water at 60°C, and form an emulsion after stirring; then inject the aluminum hydroxide modified epoxy resin latex in...

Embodiment 2

[0050] Aluminum hydroxide used in the embodiment

[0051]

[0052] raw material:

[0053] 100 parts of road grade A matrix asphalt, 15 parts of aluminum hydroxide modified epoxy resin latex, 3 parts of SBS modified latex (solid content 40%), 2 parts of cationic mid-cracking emulsifier, special inorganic aluminum hydroxide surfactant (Span surfactant) 2 parts, water 35 parts; Aluminum hydroxide modified epoxy resin latex consists of 100 parts of epichlorohydrin, 100 parts of bisphenol A, and 10 parts of aluminum hydroxide.

[0054] Preparation

[0055] (1) detect aluminum hydroxide particle diameter;

[0056] (2) adopting aluminum hydroxide, epichlorohydrin and bisphenol A to carry out compounding, be mixed with aluminum hydroxide modified epoxy resin latex;

[0057] (3) Heat the base asphalt to 135°C 3 hours in advance;

[0058] (4) Inject the emulsifier into water at 65°C, and form an emulsion after stirring; then inject the aluminum hydroxide modified epoxy resin latex ...

Embodiment 3

[0062] Aluminum hydroxide used in the embodiment

[0063]

[0064] formula:

[0065] 100 parts of road grade A matrix asphalt, 20 parts of aluminum hydroxide modified epoxy resin latex, 4 parts of SBS modified latex (solid content 50%), 3 parts of cationic slow-cracking emulsifier, special inorganic aluminum hydroxide surfactant (Span surfactant) 3 parts, water 40 parts; Aluminum hydroxide modified epoxy resin latex consists of 100 parts of epichlorohydrin, 100 parts of bisphenol A, and 20 parts of aluminum hydroxide.

[0066] Preparation

[0067] (1) detect aluminum hydroxide particle diameter;

[0068] (2) adopting aluminum hydroxide, epichlorohydrin and bisphenol A to carry out compounding, be mixed with aluminum hydroxide modified epoxy resin latex;

[0069] (3) Heat the base asphalt to 140°C;

[0070] (4) Inject the emulsifier into water at 70°C, and form an emulsion after stirring; then inject the aluminum hydroxide modified epoxy resin latex into the stirred emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com