Pedaled hydraulic driving power-assisting clutch device

A clutch device and liquid drive technology, applied in the direction of clutches, mechanical equipment, etc., can solve the problems that it is difficult to meet the drilling needs of large-scale drilling rigs, it is difficult to meet the needs of new models, and the pneumatic separation speed is fast, so as to improve drilling Performance, micro-motion soft control effect, and thorough separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

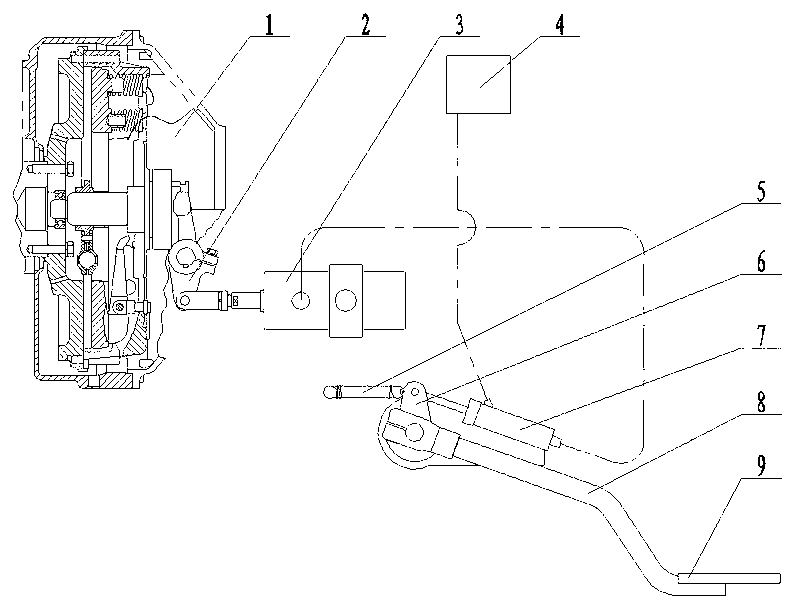

[0012] A foot hydraulic power-assisted clutch device, including a normally closed clutch 1 and a clutch operating mechanism, the normally closed clutch 1 is provided with a compression sleeve and a drive handle 2, and the drive handle 2 is connected to the compression sleeve through a fork assembly , the clutch operating mechanism includes a piston automatic reset cylinder 3 and a thrust pressurization cylinder 7, the bore of the piston automatic reset cylinder 3 is larger than that of the thrust pressurization cylinder 7, and the rear chamber of the piston automatic reset cylinder 3 is set as high-pressure closed Cavity, the front chamber of the piston automatic reset cylinder 3 is set as a booster chamber, the piston rod of the piston automatic reset cylinder passes through the booster chamber and is hinged with one end of the drive handle 2, and the thrust pressurization cylinder 7 is provided with a pressurization chamber, and the thrust The pressurized chamber of the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com