Rubber tube pressure seal tester

A sealing test and pressure technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of complicated rubber hose test process, long time required, and high test cost, and achieve easy maintenance and repair, simple connection operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

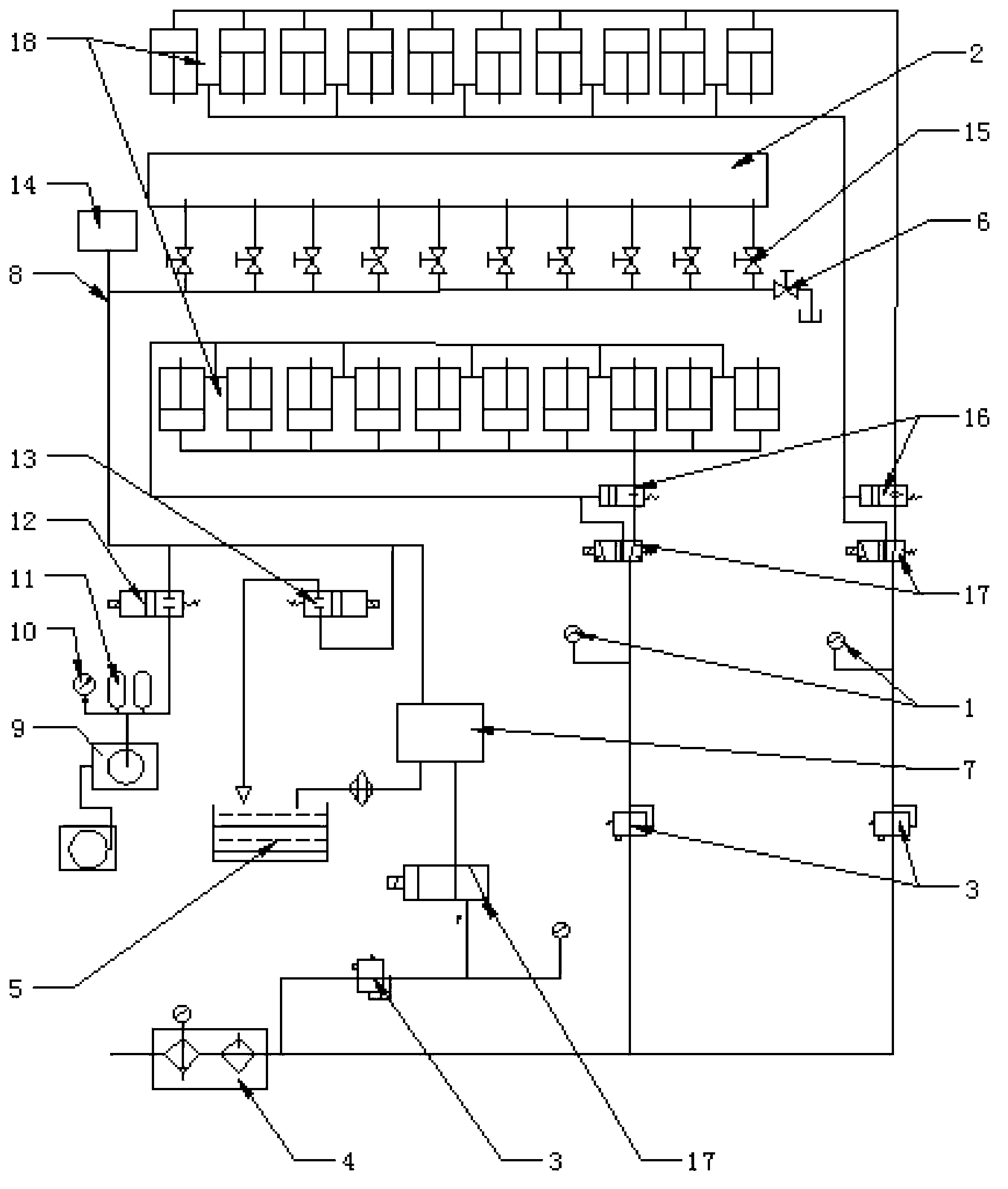

[0015] The present invention will be further described by embodiment now in conjunction with accompanying drawing. Such as figure 1 As shown, a clamping mechanism is respectively provided at both ends (upper and lower ends) of several elements (hose) 2 to be tested; each clamping mechanism includes several ( A clamping cylinder corresponds to one end of a rubber hose) clamping cylinder 18, and a clamping ferrule device including a clamping ferrule, a ferrule seat and a clamping joint; The clamping adjustment device, the clamping adjustment device is connected by two screw rods of the lifting mechanism to form a connection between the two screw rods and a driving motor, which is driven to rotate by the driving motor to adjust the distance between the upper and lower clamping mechanisms. Spacing to adapt to the tested hoses of different lengths.

[0016] Each corresponding port of each clamping cylinder 18 of each clamping mechanism is connected in parallel with each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com