Ablation testing apparatus and method for applying load on-line

A testing device and a technology for applying loads, applied in measurement devices, mechanical devices, instruments, etc., can solve problems such as insufficient consideration of environmental coupling effect simulation, difficulty in building test benches, and inability to simulate and describe material responses more accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

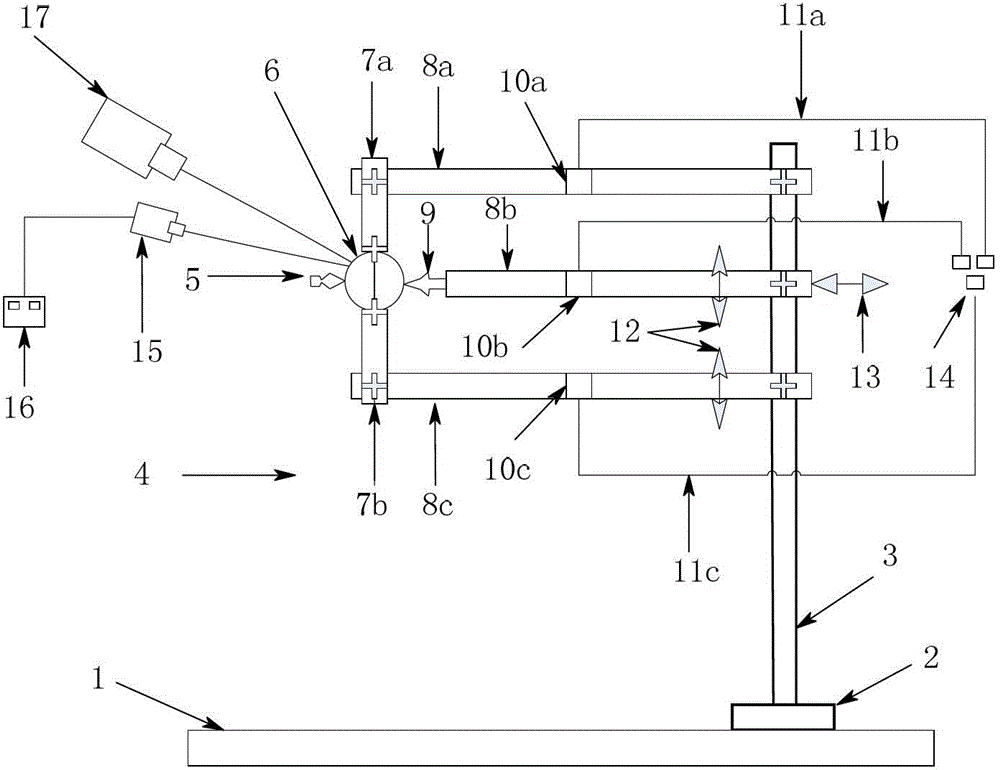

[0011] The specific structure, working process and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] figure 1 It is a schematic diagram of the structure and principle of an ablation test device for applying load online, and the test device includes a sample holding device, a load applying device, a load measuring system, an oxyacetylene heating device 4, a temperature measuring system, and an image acquisition and processing system 17; The sample holding device includes an upper chuck 7a and a lower chuck 7b, and the load applying device includes a base 2, a support 3, an upper link 8a, a middle link 8b, a lower link 8c, a loading head 9 and a loading knob 13 , the upper link 8a, the middle link 8b, and the lower link 8c are installed on the support 3; the upper chuck 7a and the lower chuck 7b are fixedly connected with the upper link 8a and the lower link 8c respectively; the load measuring sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com