Yarn or fabric surface characteristics optical and mechanical combination measurement method and apparatus

A measuring device, yarn technology, applied in the direction of measuring devices, textile testing, using mechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

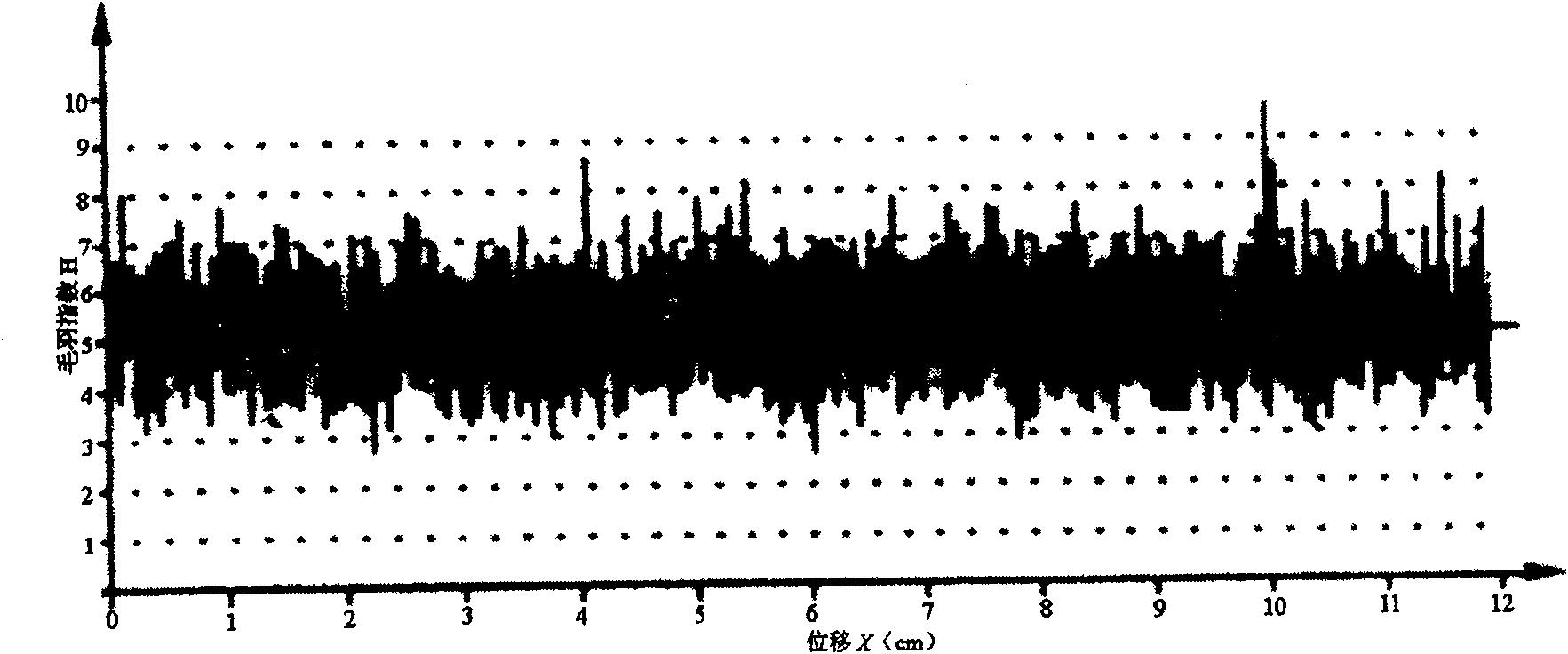

[0045] Embodiment 1, hairiness index-displacement curve obtains

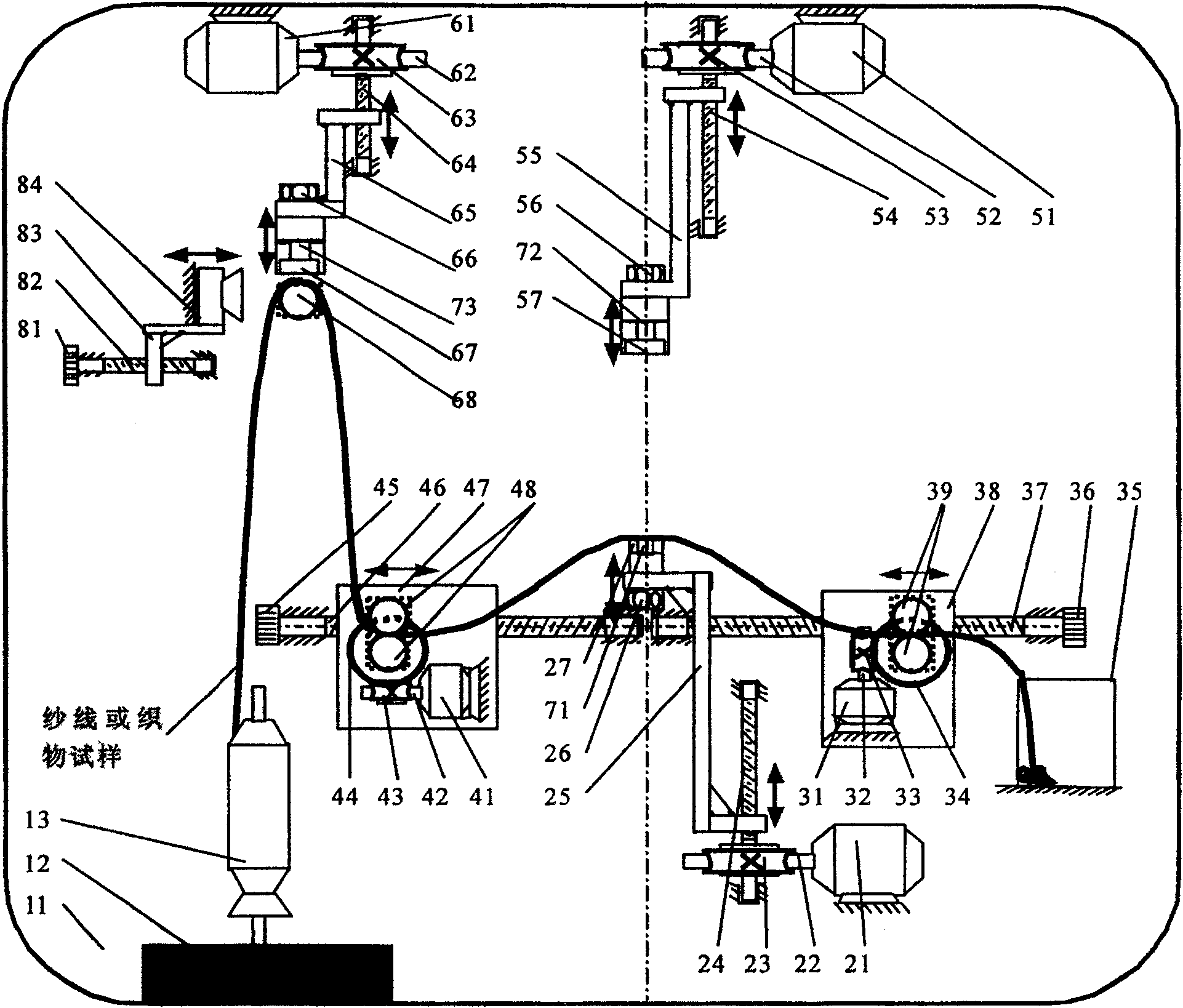

[0046] According to the measurement requirements and perform the above measurement preparation steps, fix the bobbin on the positioning rod 13, then pull the yarn along the guide roller 68 to the nip of the back roller 48, drive the back roller 48 to rotate and pull the yarn through the stepping motor 41 To the front roller 39 jaws, the stepper motor 31 drives the front roller 39 to rotate and draw the yarn to the sample bucket 35. Start the high-resolution digital CCD camera 84 to capture the surface morphology of the sample on the guide roller 68 within a set period of time, and obtain the hairiness index-displacement curve as shown in figure 2 .

Embodiment 2

[0047] Embodiment 2, apparent thickness parameter obtains

[0048] According to the measurement requirements, the fabric sample cut to a certain length and width is loosely placed on the positioning rod 13, and then the fabric is pulled along the guide roller 68 to the nip of the back roller 48, and the back roller 48 is driven by the stepping motor 41 to rotate and pull the fabric to At the front roller 39 jaws, the stepper motor 31 drives the front roller 39 to rotate and draw the fabric to the sample bucket 35. The driving circuit drives the stepper motor 61 to rotate the screw rod 64 to drive the grip rod 65 and the compression block 67 to move down vertically to compress the surface of the sample on the guide roller 68, and the pressure is induced by the force sensor 73 connected to the compression block 67, Thus, the pressure-displacement curve and the sample thickness-pressure curve are obtained. According to the sample thickness (H1, H2) measured under the action of tw...

Embodiment 3

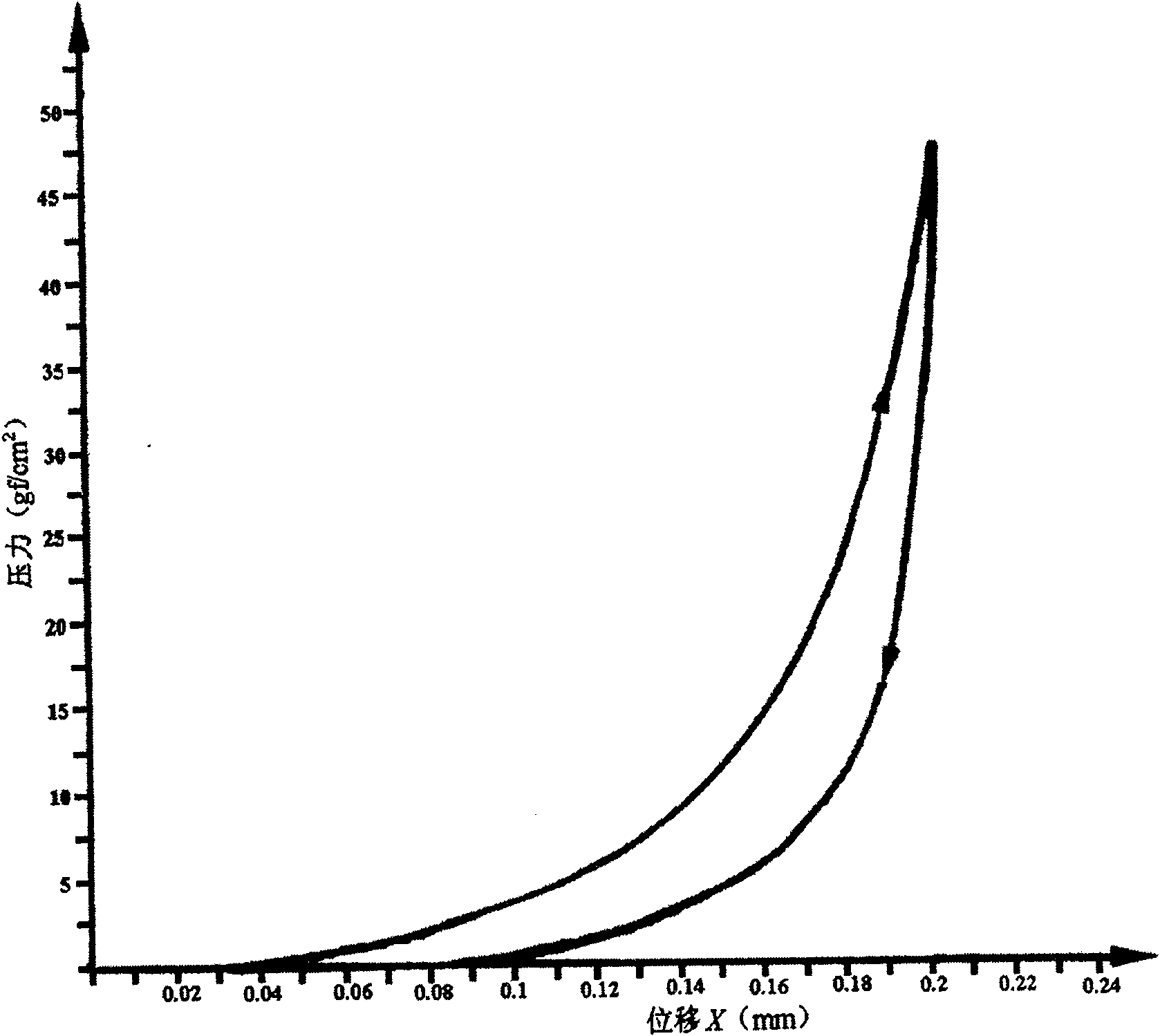

[0051] Embodiment 3, pressure-displacement curve and parameter acquisition

[0052] According to measurement requirements, cut the fabric sample of certain length * width, after the test procedure of embodiment 2 is finished, drive the stepper motor 51 to rotate the screw rod 54 to drive the holding rod 55 and the briquetting block 57 to compress the sample in cycle (cycle) The number of times can be set, and the present embodiment only does one cycle), thus obtaining the pressure-displacement curve see image 3 , according to the pressure-displacement curve, the corresponding mechanical characteristic parameters can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com