An online fabric defect detection and alarm system based on machine vision

A defect detection and alarm system technology, applied in the field of detection systems, can solve problems such as inability to intervene in fabric production, and achieve the effects of improving defect identification efficiency, reducing fabric defective rate, and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The architecture of the online fabric defect detection and alarm system based on machine vision of the present invention will be described in detail below with reference to the accompanying drawings, but this does not constitute a limitation to the present invention.

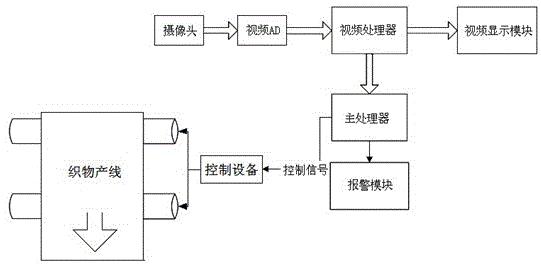

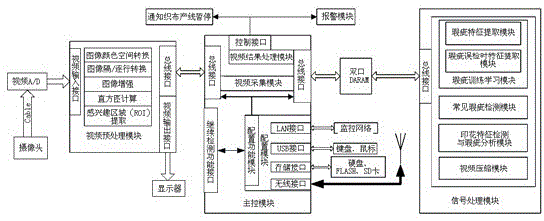

[0025] An online fabric defect detection and alarm system based on machine vision of the present invention such as figure 1 shown. In the process of fabric production, high-definition and high-speed cameras are used to obtain online video of fabrics. The acquired online video is digitally processed by the video AD, collected and preprocessed by the video processor, and can be output to a video terminal, such as a liquid crystal display, etc. through the video processor. The collected video is processed by the main processor intelligently, mainly including video feature extraction, common defect detection (using multi-mode adaptive defect detection method), printing defect detection and other functions. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com