Purifying device for cutting fluid

A purification device and cutting fluid technology, applied in the direction of chemical instruments and methods, maintenance and safety accessories, filter circuits, etc., can solve the problems of damaged tools, waste, and reduced processing accuracy, and achieve cost reduction, convenient operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0011] The technical scheme of concrete implementation of the present invention is:

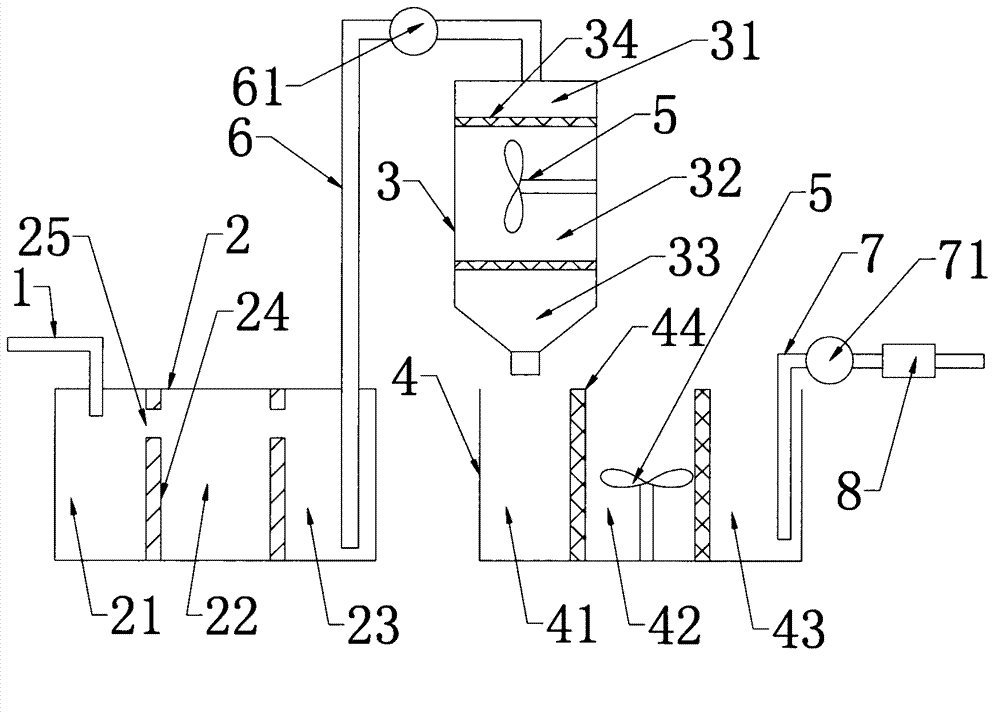

[0012] A cutting fluid purification device, including a waste liquid input pipe 1, a sedimentation tank 2, a filter tank 3 and a clean liquid tank 4; the sedimentation tank 2 is divided into a first sedimentation bin 21, a second The sedimentation bin 22 and the third sedimentation bin 23, the top of the partition plate 24 is provided with an overflow port 25; the filter tank 3 is divided into the first filter bin 31 and the second filter bin 31 distributed from top to bottom by two horizontally arranged filter plates 34. Bin 32 and the third filter bin 33; the net liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com