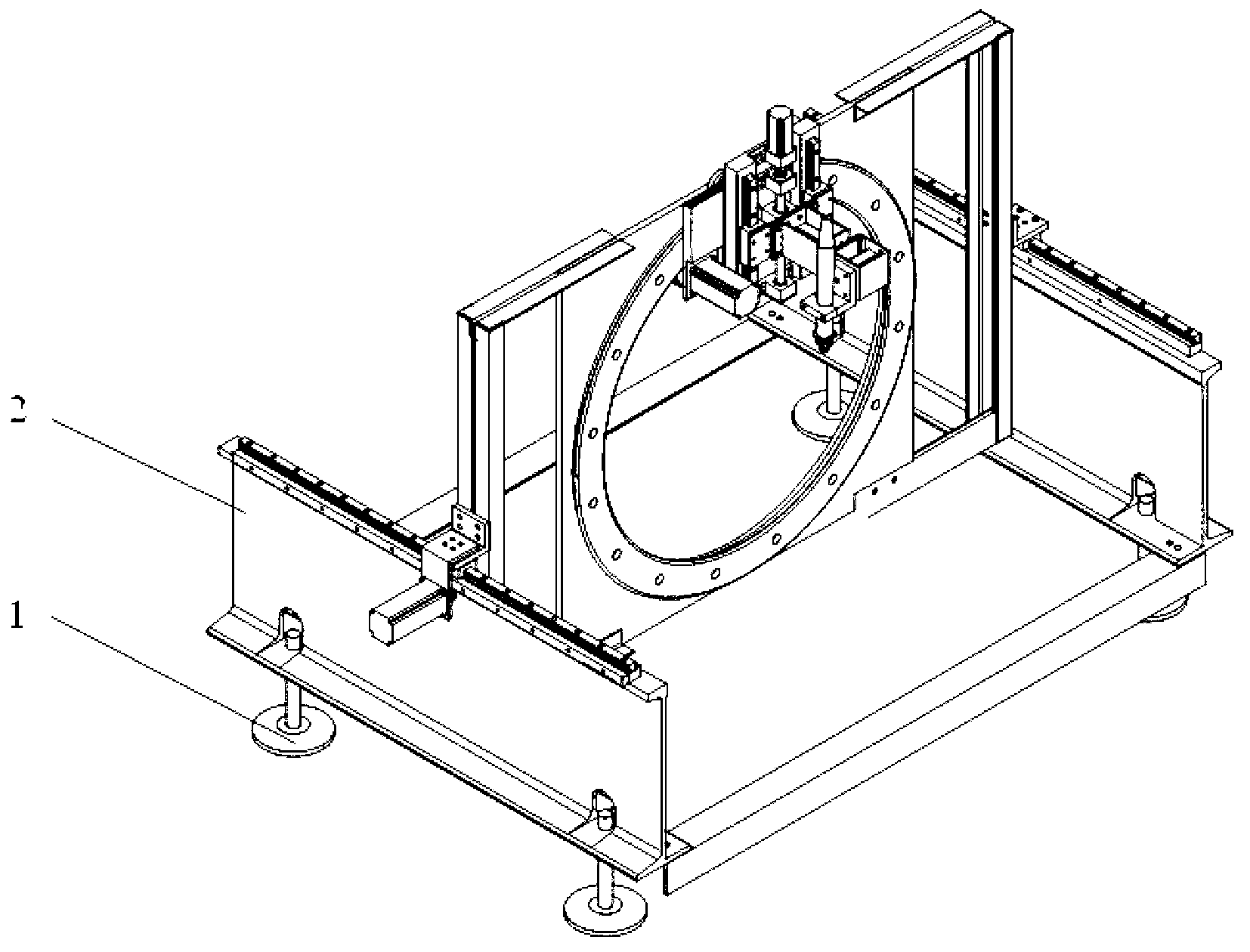

Device for cutting steel intermediate bend intersecting line

A technology of intersecting lines and elbows, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problem of not being able to cut intersecting lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

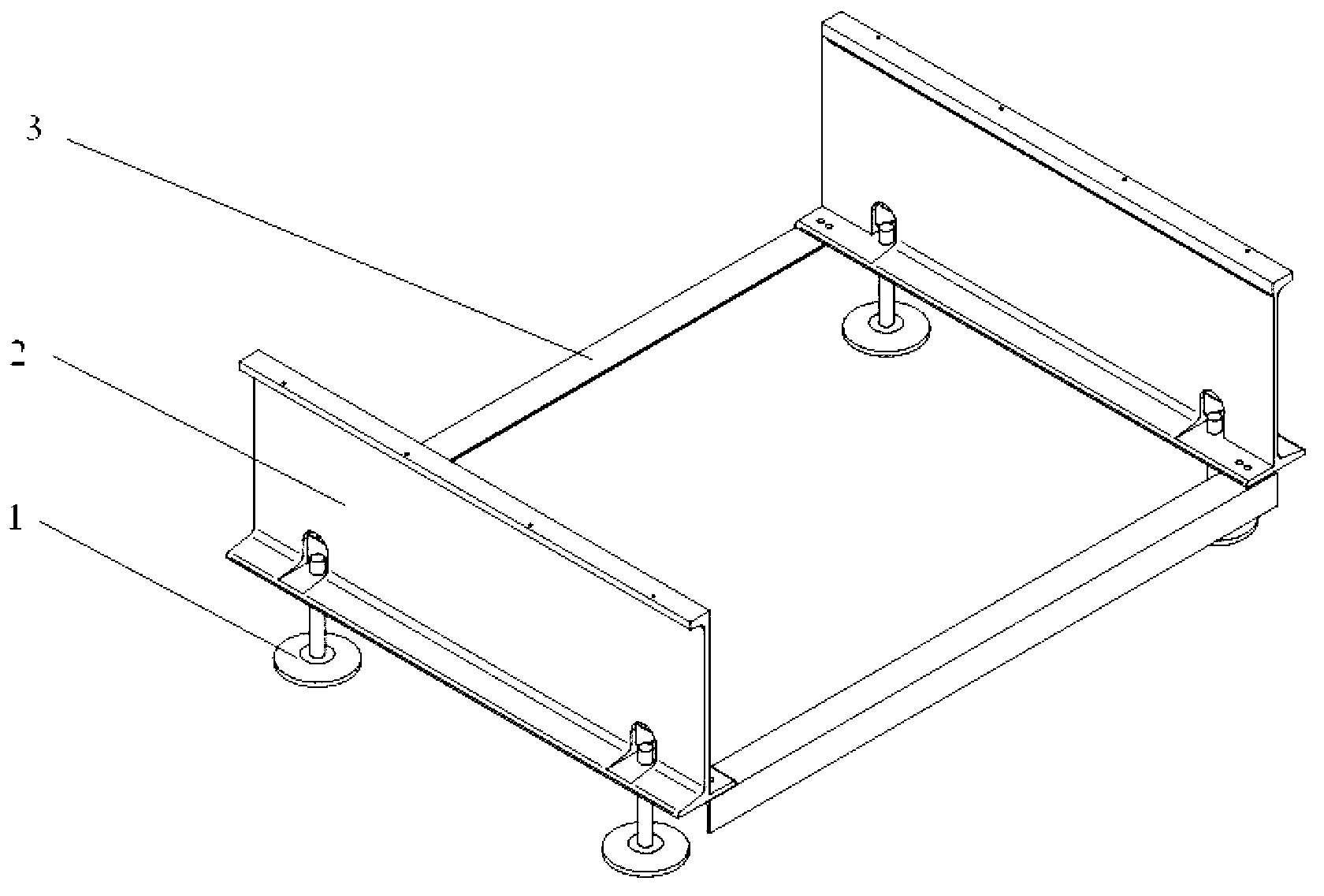

[0027] like figure 1 and figure 2 As shown, under the vertical support 2 of the frame, the support foot 1 is set, and the thread is arranged on the support foot 1, and the thread is provided in the matching hole of the vertical support 2 of the frame and the support foot. Support 2 and the screw thread that support foot 1 cooperates hole to set, adjust the matching position of support foot 1 and frame vertical support 2, thereby regulate the height of frame vertical support 2, adjust the height of whole cutting device. Through holes are provided at both ends of the longitudinal support 2 of the frame, and through holes are provided at both ends of the horizontal support 3 of the frame, and the through holes at both ends of the longitudinal support 2 of the frame and the through holes at both ends of the horizontal support 3 of the frame are passed through the bolt and nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com