A track assembly and a sliding door

A track and component technology, applied to windows/doors, wing leaf parts, building components, etc., can solve problems such as top gaps, inconvenient concealment, inconvenient installation and replacement parts, etc., to improve the appearance and make the installation process simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

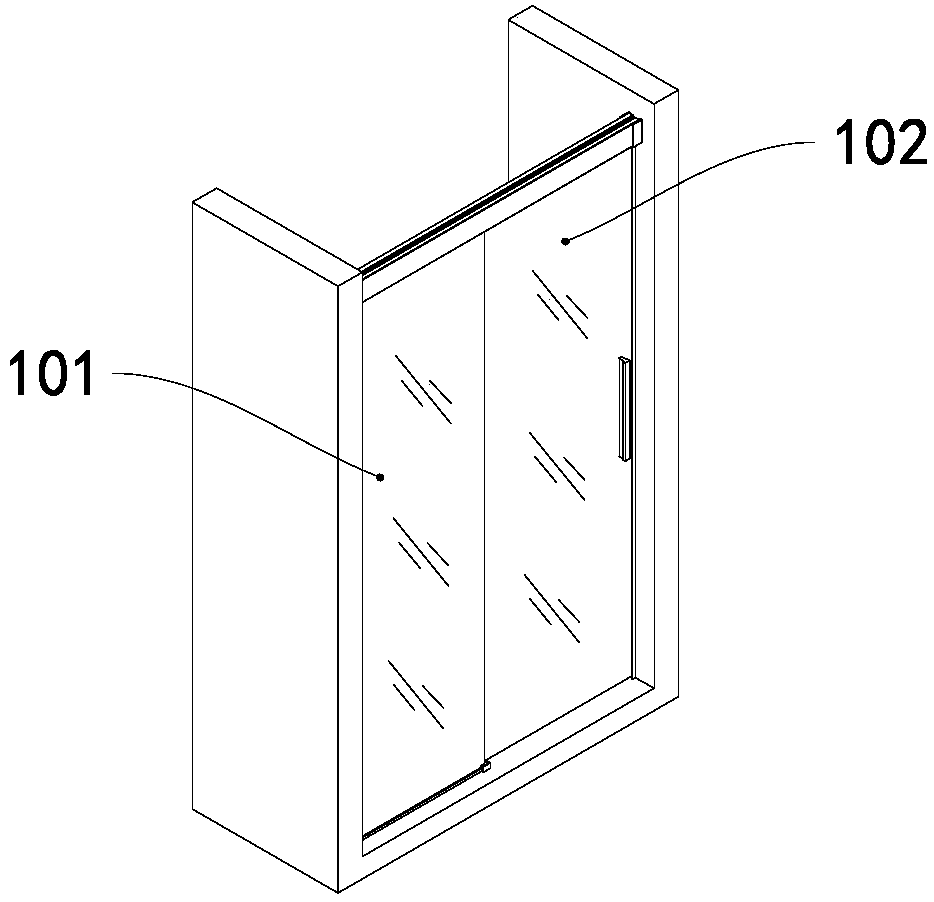

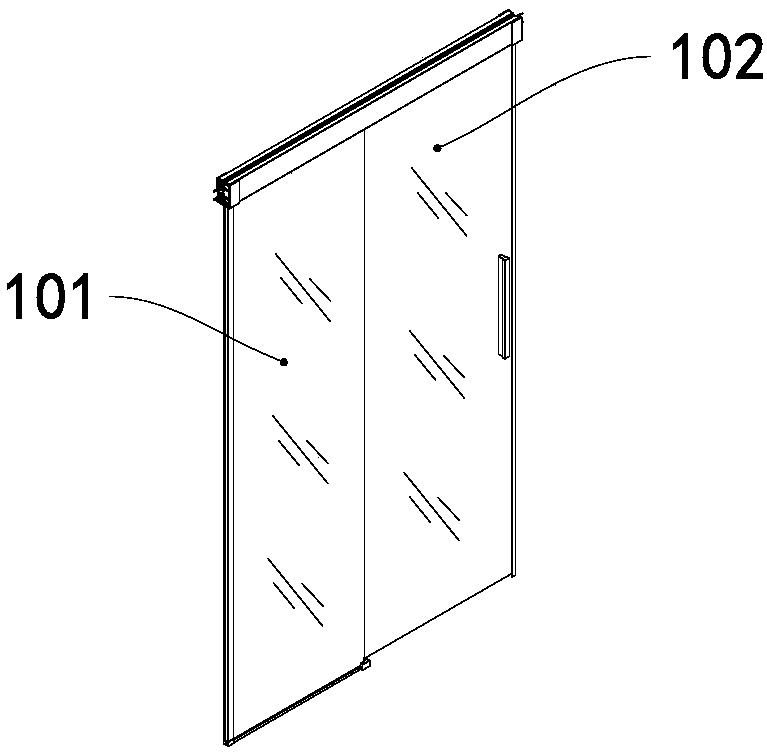

[0044] Sliding door first embodiment: see Figure 1 to Figure 2 , the sliding door of this embodiment is installed between the walls, and is a single door type sliding door, including a fixed door 101 and a movable door 102, and the fixed door 101 and the movable door 102 are provided with track assemblies. The movable door 102 can slide relative to the fixed door 101 .

no. 2 example

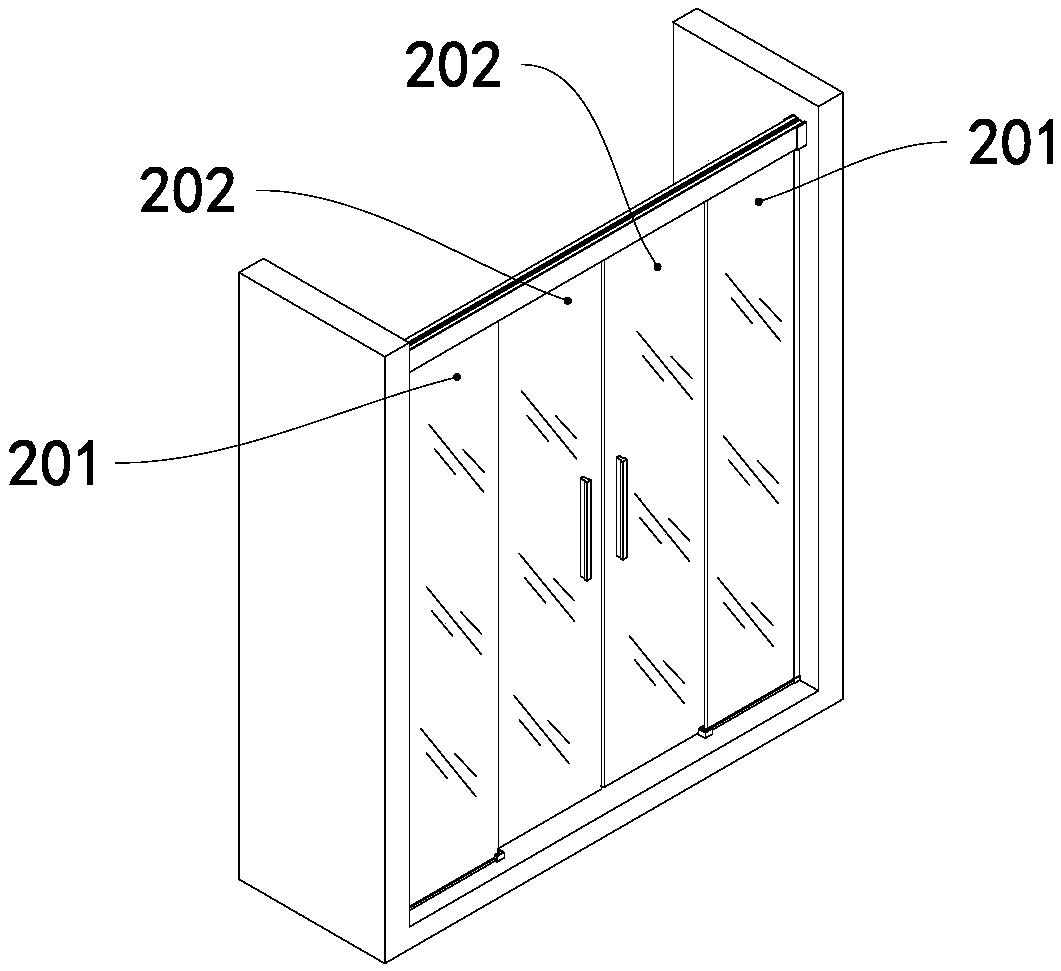

[0045] The second embodiment of the sliding door: see Figure 3 to Figure 4 , the sliding door of this embodiment is installed between the walls, and is a double-door type sliding door, including two fixed doors 201 and two movable doors 202 . The fixed door 201 is located next to the wall, and the movable door 202 is located in the middle. Track assemblies are arranged on the fixed door 201 and the movable door 202 . The movable door 202 can slide relative to the fixed door 201 .

[0046] Example track assembly:

[0047] The following describes the embodiment of the track assembly in detail in conjunction with the use of the track assembly in the first embodiment of the sliding door.

[0048] see Figure 5 to Figure 6 , the track assembly includes a track 300 , a buffer piece 400 , a trigger piece 500 and a sliding piece 600 . see Figure 7 to Figure 9 , the track 300 includes a vertical track body 320, a first cavity 370 is provided in the middle of the track body 320,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com