Corner drawing forming and both edge correcting device

A stretch forming, bilateral technology, applied in the field of machinery, can solve the problems of low product quality and complex processing procedures, and achieve the effects of high processing accuracy, saving human resources and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

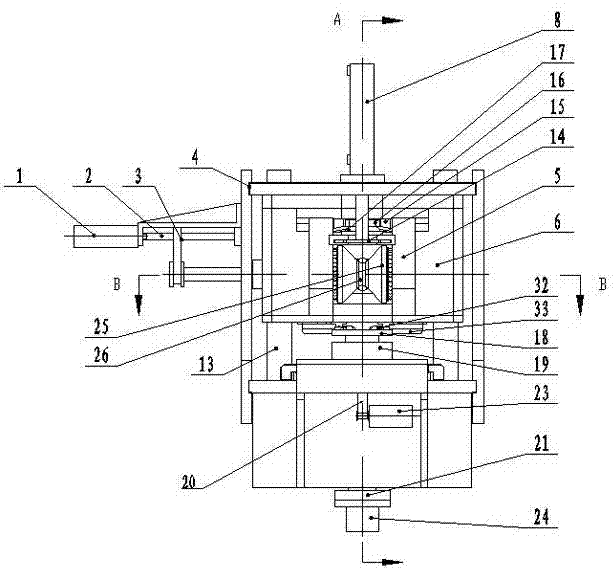

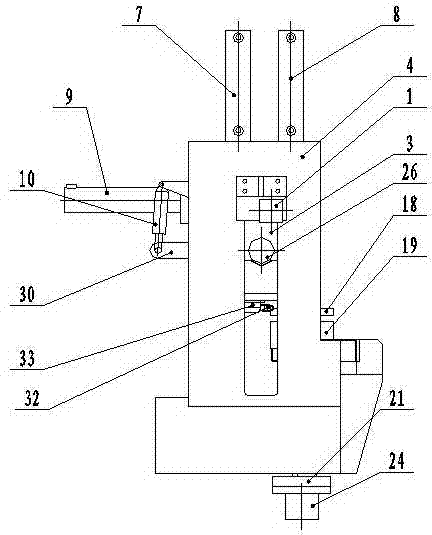

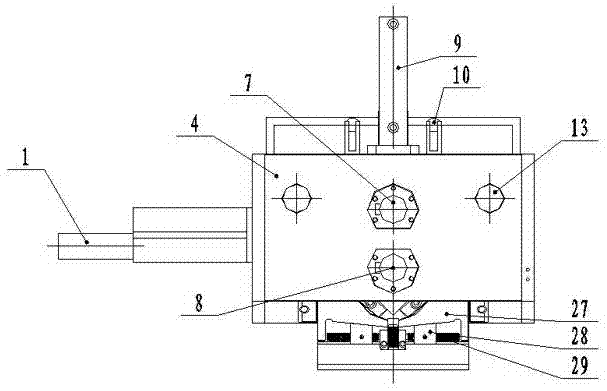

[0027] In order to better understand and implement, a kind of corner stretch forming bilateral correction device of the present invention will be described in detail below in conjunction with the examples: Taking the multi-station axial forming roller as an example with 6 stations, the corner stretch forming bilateral correction The device includes a bed 4 and a pressing device arranged on the bed, a shaft type quick-change forming device, an integrated shearing device, and a corner forming bilateral correction device; the pressing device includes a pressing cylinder 8, a pressing plate 14, The pressing oil cylinder 8 is installed on the bed 4, and the pressing plate 14 is installed on the piston rod of the pressing oil cylinder 8, which can provide the effect of fixing the workpiece for forming, shearing, and corner forming bilateral correction.

[0028] The shaft-type quick-change molding device includes multi-station shaft-type forming rollers 26, forming guide wheels 25, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com