Injection molding machine testing mold and device

A technology for injection molding machines and molds, applied in the field of injection molding machine testing devices, can solve problems such as time-consuming, difficult to achieve predetermined functions of pressurized cylinders, and strengthening tie rods, etc., to achieve accurate and convenient testing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing embodiment to this invention for further description.

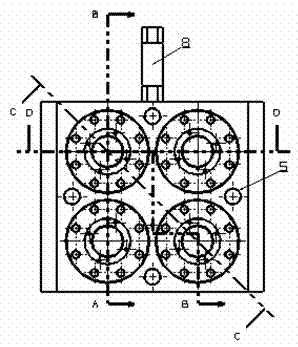

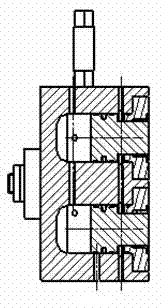

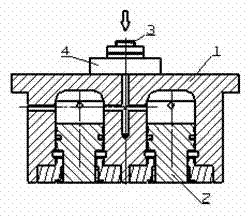

[0022] like figure 1 , Figure 2, image 3 , as shown in Figure 4, the mold for injection molding machine testing includes cavity body 1, pusher piston 2, ejector piston 3, ejector piston cover 4, pusher piston cover 5, high pressure resistant seal 6, guide belt 7, Check valve 8.

[0023] Die pushing piston 2 is placed on die cavity main body 1 side, and is fixed by pushing die piston cover 5, forms pushing die oil cylinder.

[0024] The ejector rod piston 4 is placed on the other side of the mold cavity main body 1, and is fixed by the ejector rod piston cover 4 to form an ejector rod oil cylinder.

[0025] The rodless chamber of the mold pushing cylinder communicates with the rodless chamber of the ejector cylinder, and the rodless chamber of the mold pushing cylinder is fed into and controlled by the high pressure resistant one-way valve 8.

[0026] The cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com