Motor transmission shaft torsion testing tool

A technology of torque testing and motor transmission, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as lack of testing equipment, difficult testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

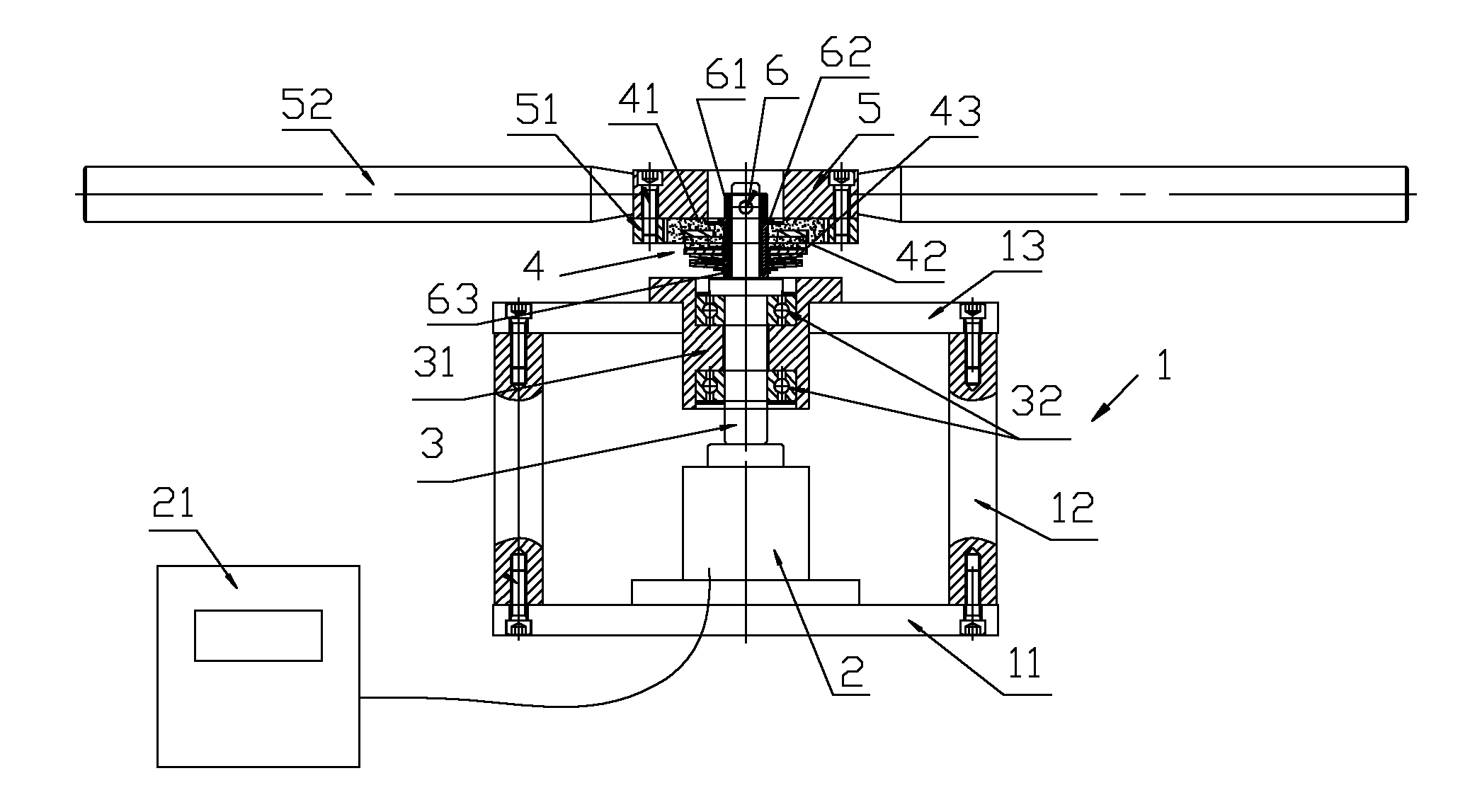

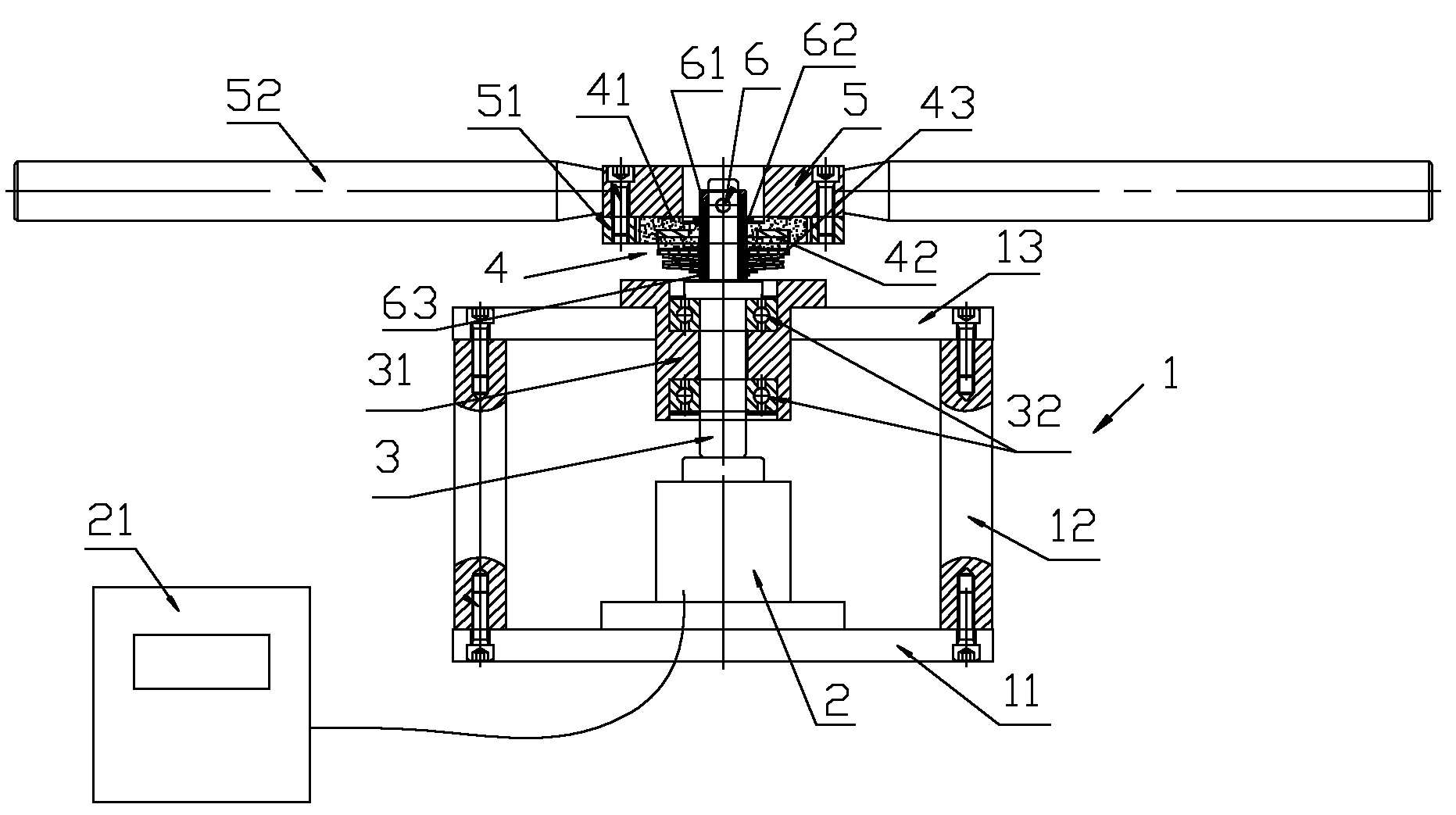

[0012] Such as figure 1 As shown, it is an embodiment of the motor transmission shaft torsion test tooling of the present invention, including a frame 1, on which a transmission connecting shaft 3 is arranged for vertical rotation, and a torque sensor 2 is provided at the bottom of the frame, and the torque sensor passes through a signal line It is connected with the digital torque display instrument 21, the lower end of the transmission connection shaft is connected with the torque sensor, the upper end of the transmission connection shaft extends out of the frame and is sleeved with the butterfly spring gear assembly 4, and the gear 41 of the butterfly spring gear assembly is provided with a The rotating mechanism drives the gears to rotate. The rotating mechanism includes a locating ring 5, and the fixed outer ring is provided with a test handle 52 that drives the locating ring to rotate. The lower part of the locating ring is fixed with a test ring gear 51. gears meshing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com