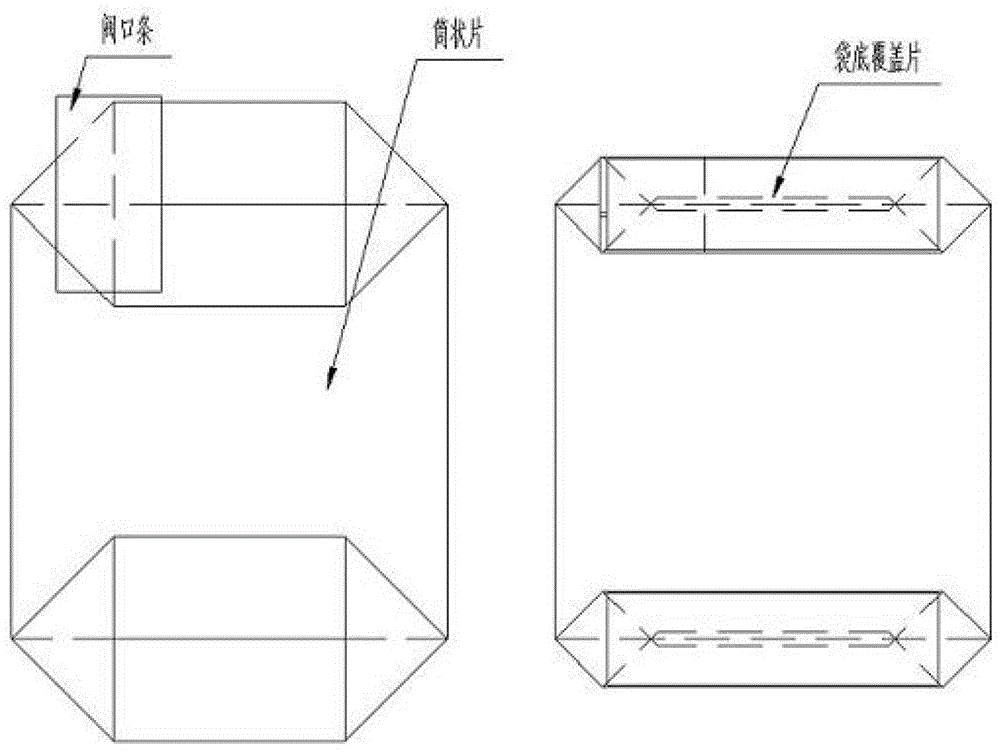

Hot-gas welding press fit device for valve strips or bag bottom covering sheets of block bottom valve bags

A technology of covering sheets and square bottom valves, which is applied in packaging, transportation and packaging, and the manufacture of rigid/semi-rigid containers, etc., can solve problems such as unprovided solutions, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

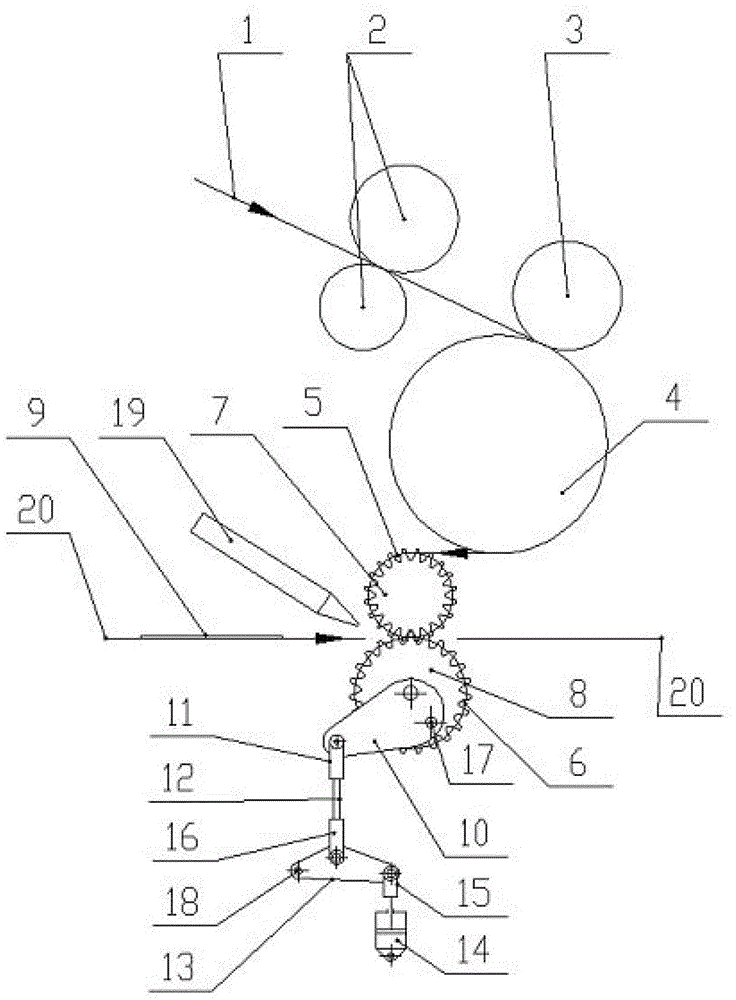

[0026] like figure 2 As shown, the conveying device (not shown in the figure) beats the delivery tube bag piece 9 on the platform plate 20 of the frame (not shown in the figure);

[0027] Installed on the top of the platform plate 20, perpendicular to the moving direction of the tube bag sheet 9, a coil feeding device is fixed in a cantilever bracket type; A cutting device composed of rotating hob 4;

[0028] Secondly, the welding and pressing device is composed of the negative pressure transfer roller 5 and the lower pressing roller 6, which is installed in the gap provided on the platform plate 20, and the tangent at the corresponding gap is roughly at the same level as the platform plate 20, and the cylinder The valve strip or bag bottom cover sheet cut from the bag piece 9 and the roll material 1 passes through the gap;

[0029] The negative pressure transfer roller 5 and the lower pressing roller 6 are respectively driven by the driving gear I7 and the driving gear II8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com