Assembling Method of Cable-Stayed Bridge Hanging Basket

A cable-stayed bridge and assembly technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inconvenient erection and dismantling, large number of supporting materials, and high lifting height of hanging baskets, so as to reduce the cost of lifting and installation. Risks, overcoming the high height of the bridge deck, overcoming the effect of the narrow construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment, the assembling method of cable-stayed bridge suspension basket of the present invention is further detailed as follows:

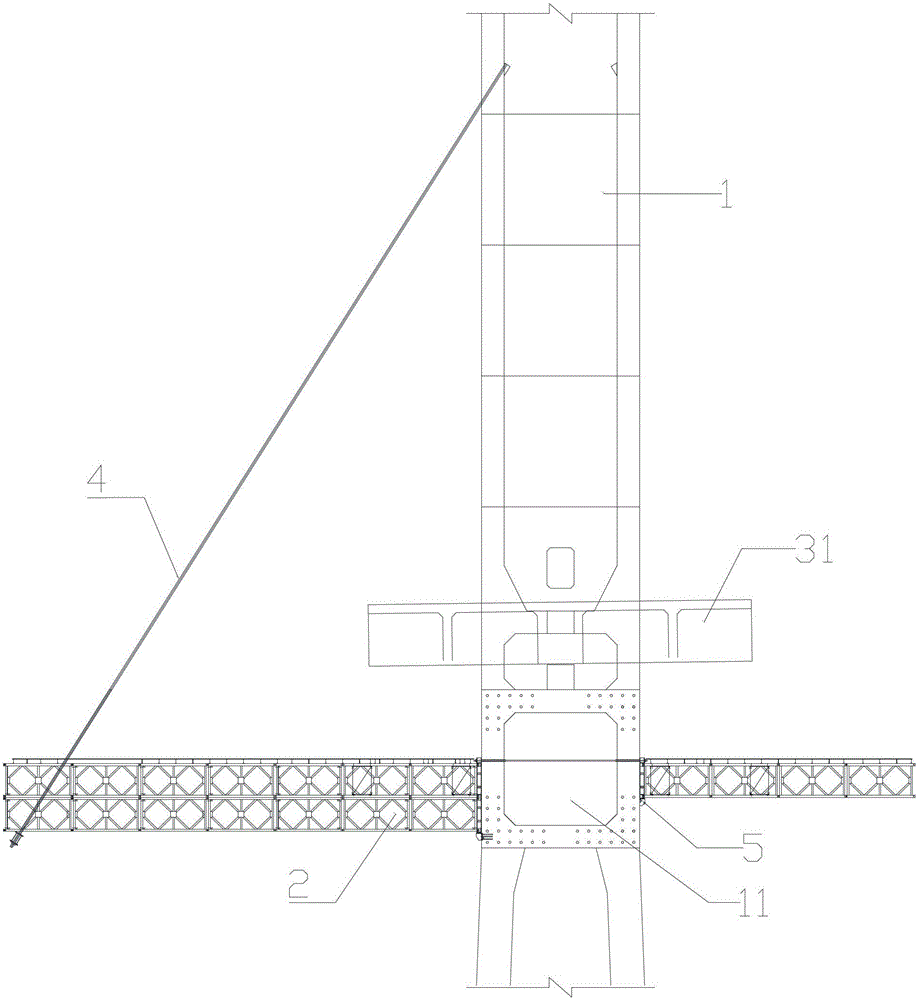

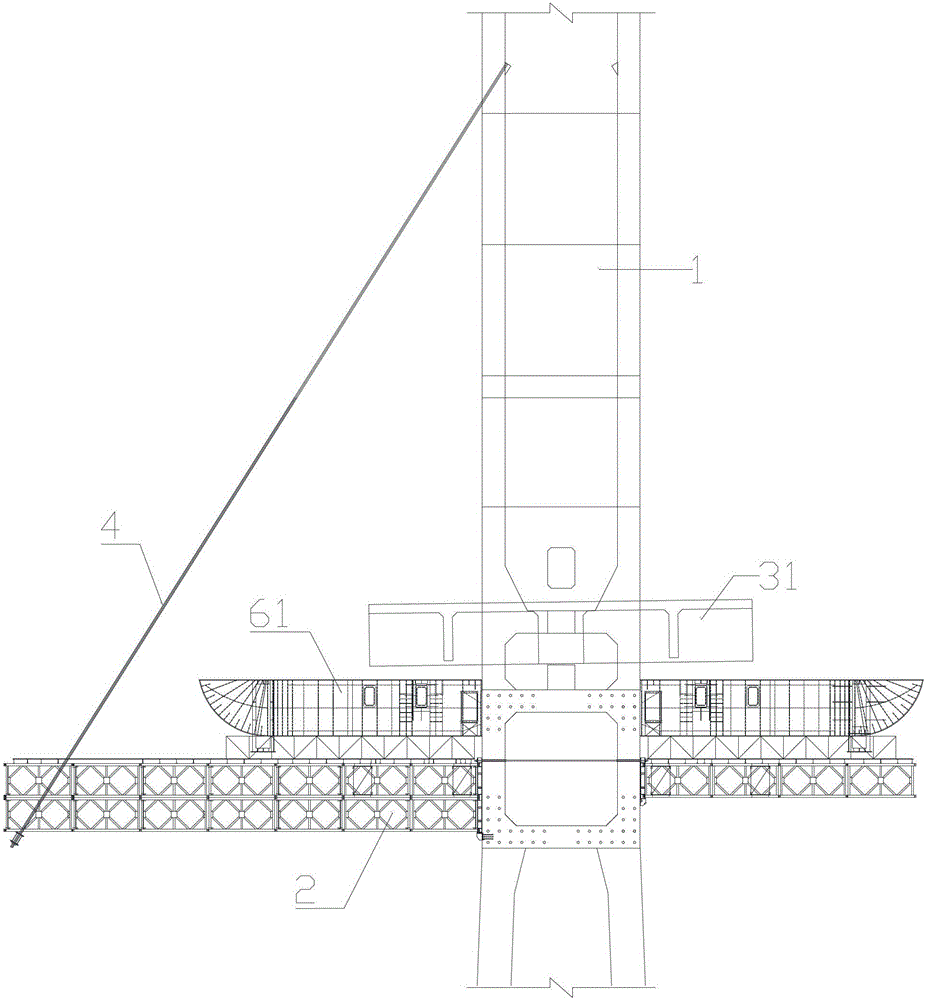

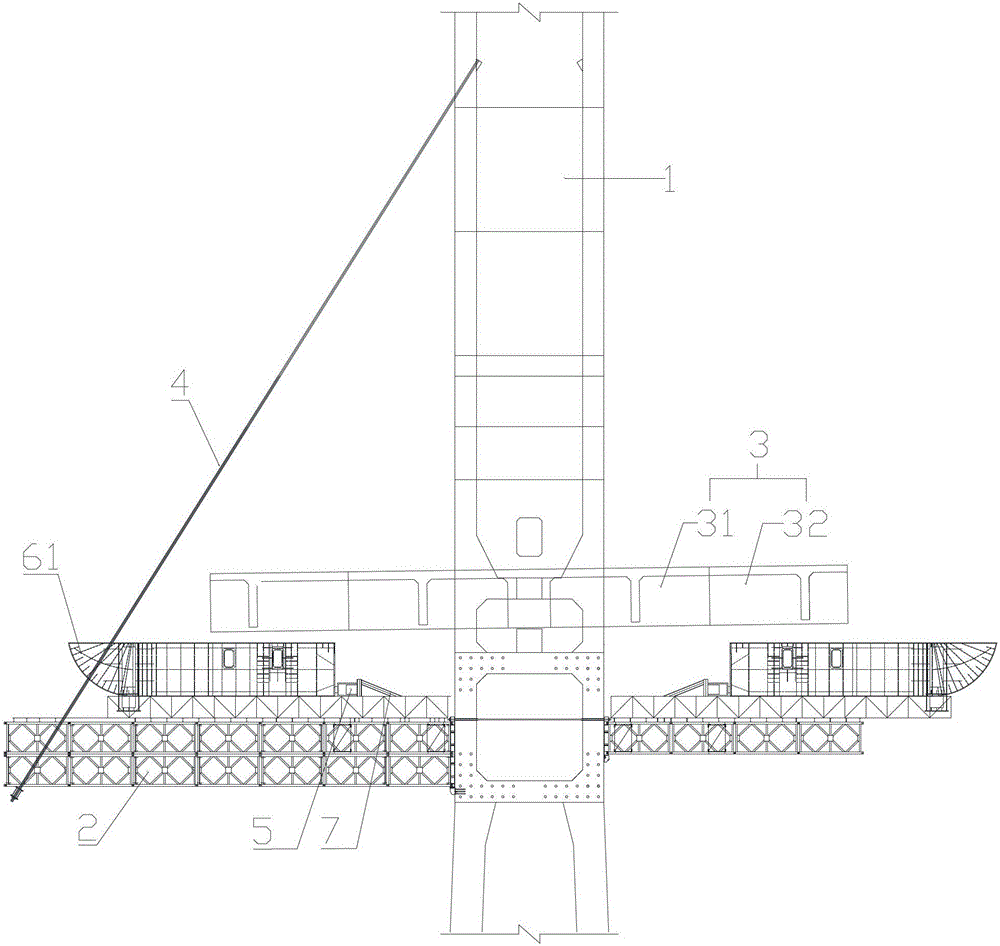

[0031] refer to Figure 1-6 , at first, install the Bailey truss bracket 2 on both sides of the lower beam 11 of the cable tower 1 that has been built; secondly, use the Bailey truss bracket 2 as a work platform to pour the 0 of the cable-stayed bridge. -1# main beam 31, such as figure 1 As shown, the installation of the assembling platform (not marked) of the dragline hanging basket is completed so far.

[0032] The cable tower 1 also includes corbels 5 pre-buried on both sides of its lower beam 11 and temporary cables 4 arranged on its tower column. The bracket 2 makes full use of the structural characteristics of the cable-stayed bridge, and its rear end is fixed on both sides of the lower beam 11 of the cable tower 1 by using the corbel 5 and finished-rolled rebar (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com