New-old bridge transverse reinforced steel frame for broadening modification of hollow slab bridge and construction process

A technology of hollow slab bridge and construction technology, which is applied in bridges, bridge maintenance, bridge reinforcement, etc. It can solve the problems of large shear force at the old and new joints, force on the single plate of the old bridge side plate, relative displacement of the new and old slabs, etc. , to achieve the effect of solving veneer damage and driving instability, strengthening integrity, and smooth transition of horizontal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

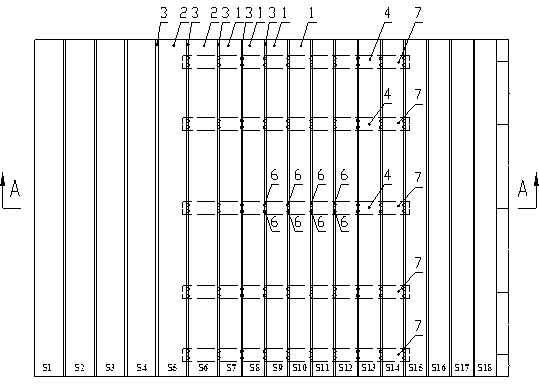

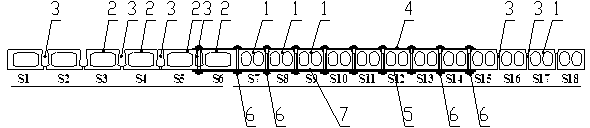

[0050] This embodiment is suitable for widening and reconstruction projects of hollow slab bridges with a span L not greater than 16m, such as figure 1 , 2 As shown, the hollow slab bridge includes an old bridge composed of 12 old bridge hollow slabs 1 and a new bridge composed of 6 new bridge hollow slabs 2 . The number of the hollow plate is as figure 1 , 2 As shown, the numbers of the hollow slabs 2 of the new bridge are S1~S6, and the numbers of the hollow slabs 1 of the old bridge are S7~S18. ) The top of the plate is connected by steel plate 4, and the bottom of the plate is connected by channel steel 5. The steel plate 4 on the top of the plate and the channel steel 5 on the bottom of the plate are horizontally connected into one through the bolt 6 passing through the hinge joint 3 between the plates.

[0051] A total of 5 horizontal connecting devices 7 are arranged along the longitudinal direction of the bridge span, among which 0.2~0.3, 0.45~0.65 L, 0.7~0.8 L of t...

Embodiment 2

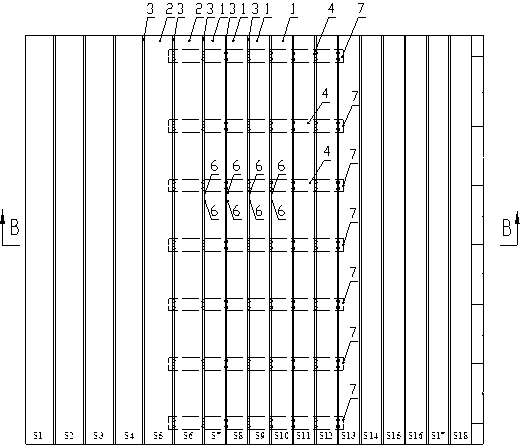

[0061] This embodiment is suitable for widening and reconstruction projects of hollow slab bridges with a span L greater than 20m.

[0062] Such as image 3 , Figure 4 As shown, the hollow slab bridge includes an old bridge composed of 12 old bridge hollow slabs 1 and a new bridge composed of 6 new bridge hollow slabs 2 . The number of the hollow plate is as image 3 , 4 As shown, the numbers of the hollow slabs 2 of the new bridge are S1~S6, and the numbers of the hollow slabs 1 of the old bridge are S7~S18. ) The top of the plate is connected by steel plate 4, and the bottom of the plate is connected by channel steel 5. The steel plate 4 on the top of the plate and the channel steel 5 on the bottom of the plate are horizontally connected into one through the bolt 6 passing through the hinge joint 3 between the plates.

[0063] A total of 7 horizontal connecting devices 7 are arranged along the longitudinal direction of the bridge span, one horizontal connecting device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com