Tool and method for inspecting size of jointed board in sleeper steel mold

An inspection tool and inspection method technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve the problems of inability to measure, complex inspection procedures, space limitations, etc., to achieve simple and fast inspection operations, improve inspection efficiency, and overcome accumulated errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The inspection tool and inspection method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

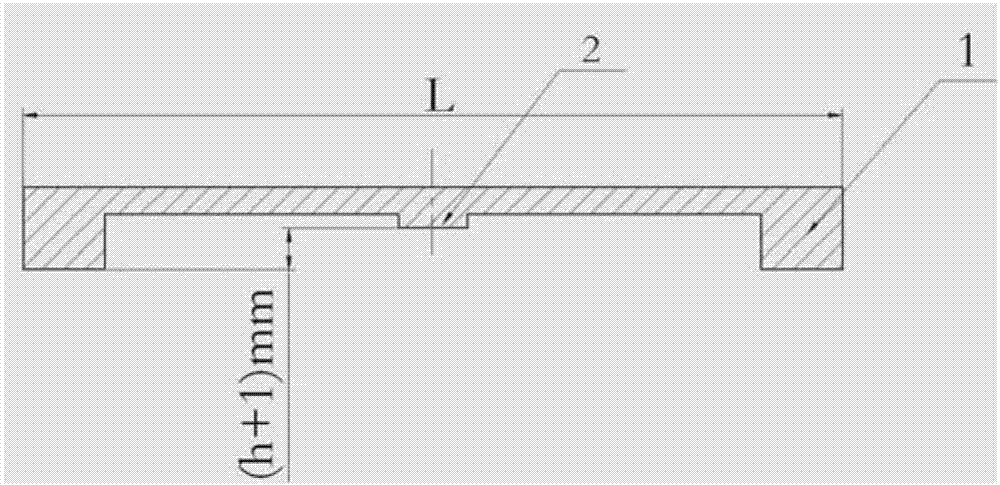

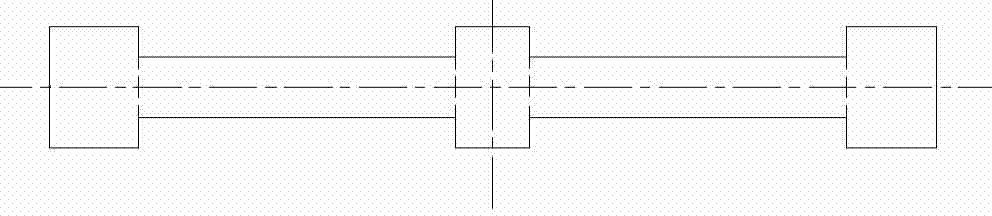

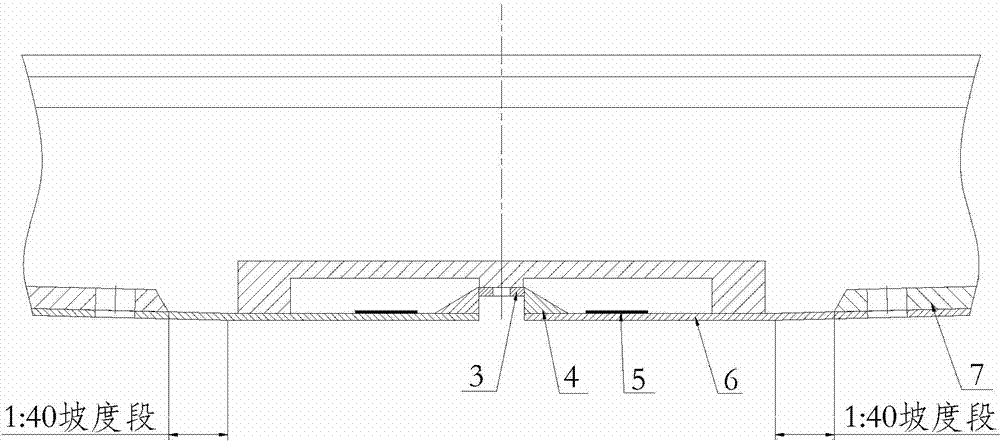

[0035] figure 1 It is a longitudinal section view of the jigsaw size inspection tool in the present invention, figure 2 It is a top view of the jigsaw size inspection tool in the present invention, image 3 It is a schematic diagram of the inspection process of the inspection tool of the present invention.

[0036] As shown in the figure, the production requirements of the inspection tool are as follows: the inspection tool includes a horizontal horizontal plate and side bumps 1 located at the lower ends of the left and right sides and a middle bump 2 in the middle, the side bumps 1 and The flatness of the measurement surface of the middle bump 2 is less than 0.05, and the parallelism between the measurement surfaces of the three bumps is less than 0.1; the height differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com