Wind power generator blade fatigue testing device and method

A technology for wind turbine blades and fatigue testing, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of high price, low cost and high cost, so as to reduce the test cost, save the test period and ensure the accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

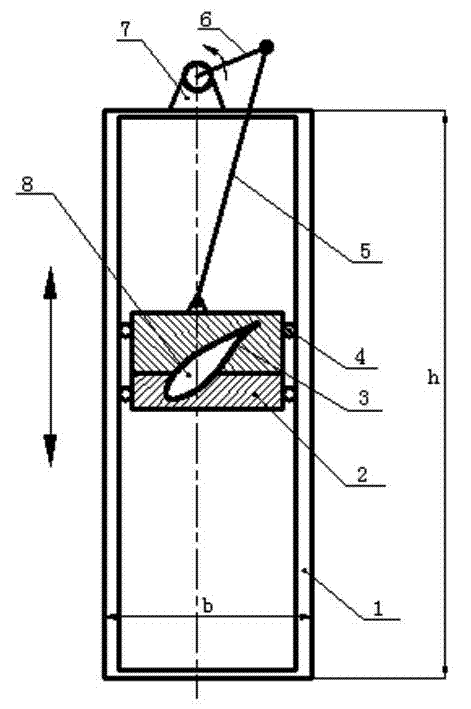

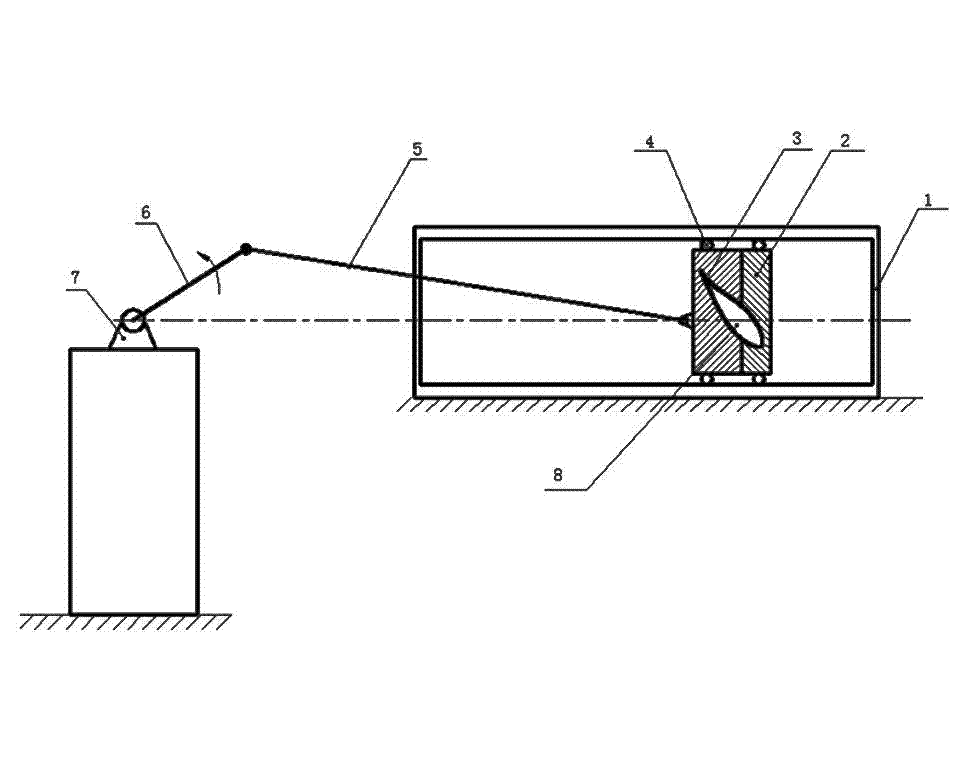

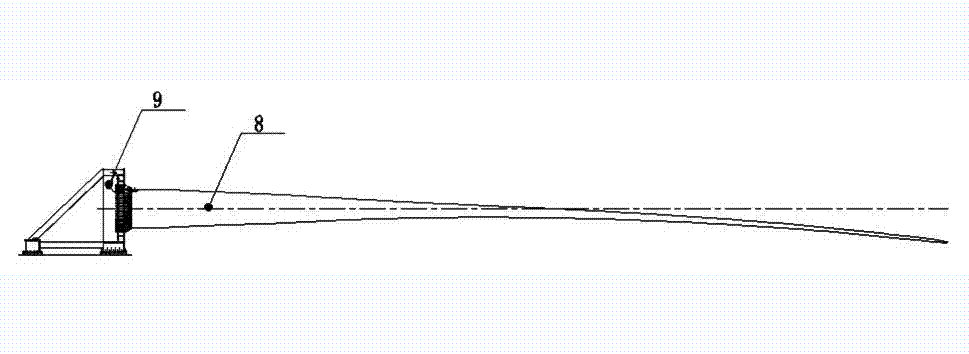

[0030] Such as Figure 1 ~ Figure 3 As shown, a wind power generation blade fatigue test device of the present invention includes a test base 9 for fixing the root of the blade 8 and a loading device for loading the blade surface of the blade 8 . The loading device in this embodiment includes a driving device, a crank connecting rod mechanism and a blade limiting device. The driving device in the present embodiment is mainly made of eccentric wheel 7, motor and reducer; One end of the connecting rod 5 is connected, and the other end of the connecting rod 5 is connected with the blade limiting device; the eccentric wheel 7 is connected with the blade limiting device through a crank linkage. The blade limiting device is a limiting device that limits the displacement of the loaded part of the blade 8 to be tested within a specific range. The blade limiting device of the present embodiment comprises a limiting base frame 1 and a tooling 2 that enables the loading part of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com