Storage battery having unit cell protection function and connecting method thereof

A technology of protection function and connection method, applied in battery pack parts, battery circuit devices, secondary battery repair/maintenance, etc., can solve the problems of inconsistent internal resistance, little effect, heat loss, etc. Vulcanization, changing the effect of mutual adverse effects, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

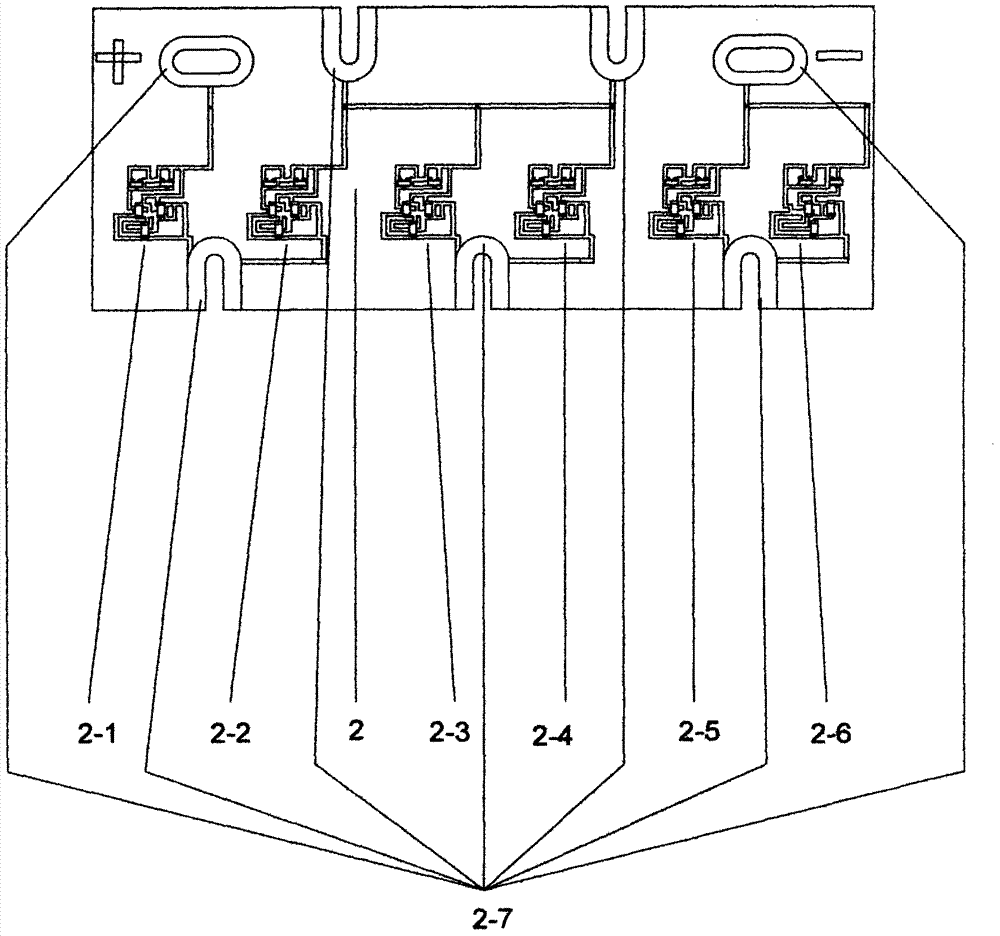

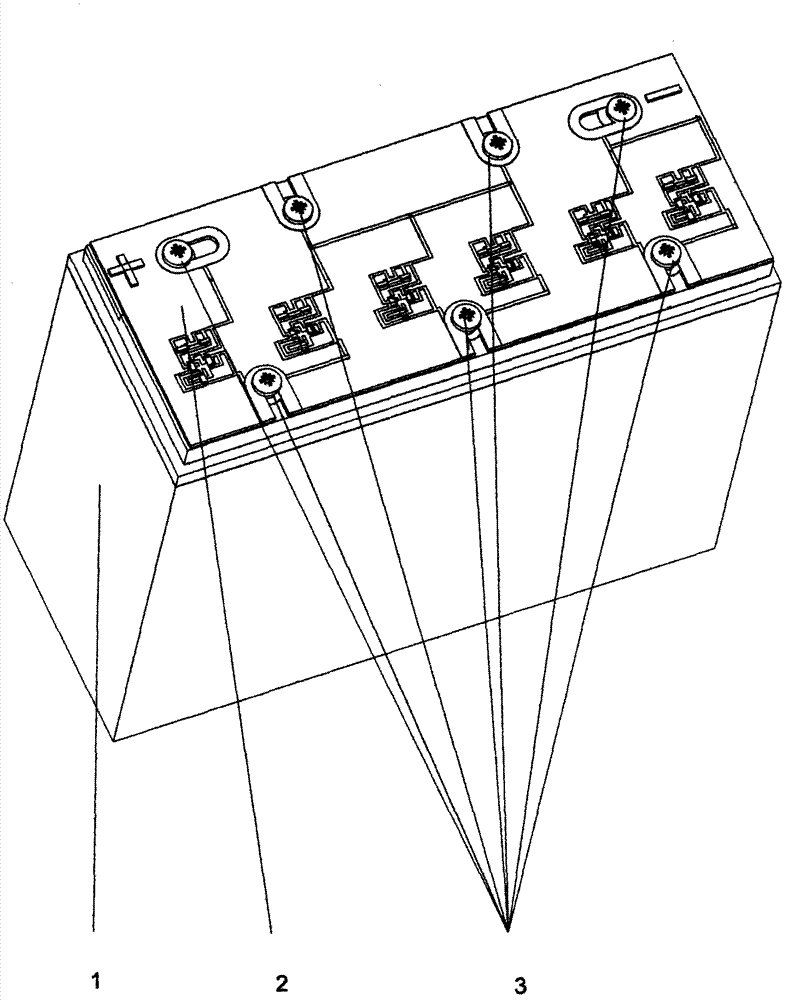

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: the storage battery with single-cell protection function and its connection method include: casing, positive and negative plates, separators, positive and negative bus bars, bridges, tabs, Upper cover, electrolyte, etc., its process method: A, replace the bridge (5) between each single cell in the original battery structure with a new bridge (6) embedded with nuts, so that the new bridge (6) The upper end is embedded with a nut (6-1), so that the novel bridge has the function of connecting screws; B, the bridge position of the battery loam cake is reserved with a screw connection hole (4).

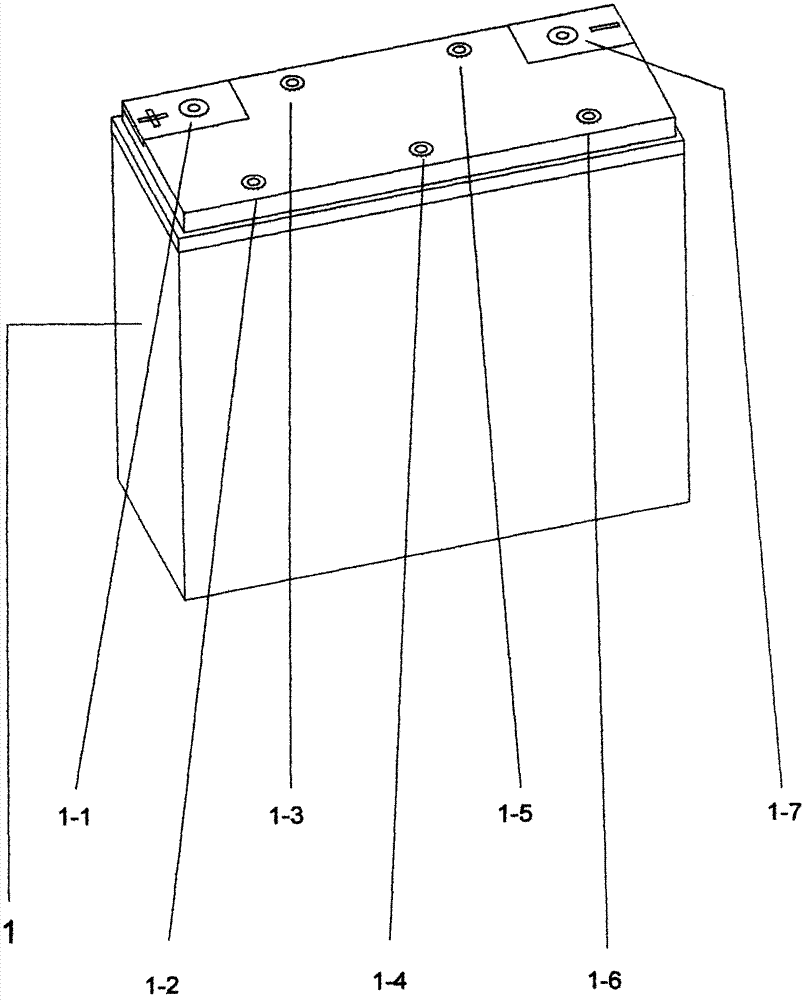

[0029] Since the storage battery adopts a new bridge (6), each cell of the storage battery has relatively independent "+, -" poles, such as figure 1 As shown, the "+" pole (1-1) of the 12v battery is also the "+" pole of the first cell, and the "+" ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com