Device and method of H-shaped parison continuous casting machine online dummy ingot

A technology for stripping ingots and continuous casting machines, which is applied to the field of on-line stripping ingot devices for H-bill continuous casting machines, can solve the problems of complex stripping ingot procedures, inconvenient cutting operations, and high ambient temperature, and achieves simple equipment structure and high process efficiency. Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

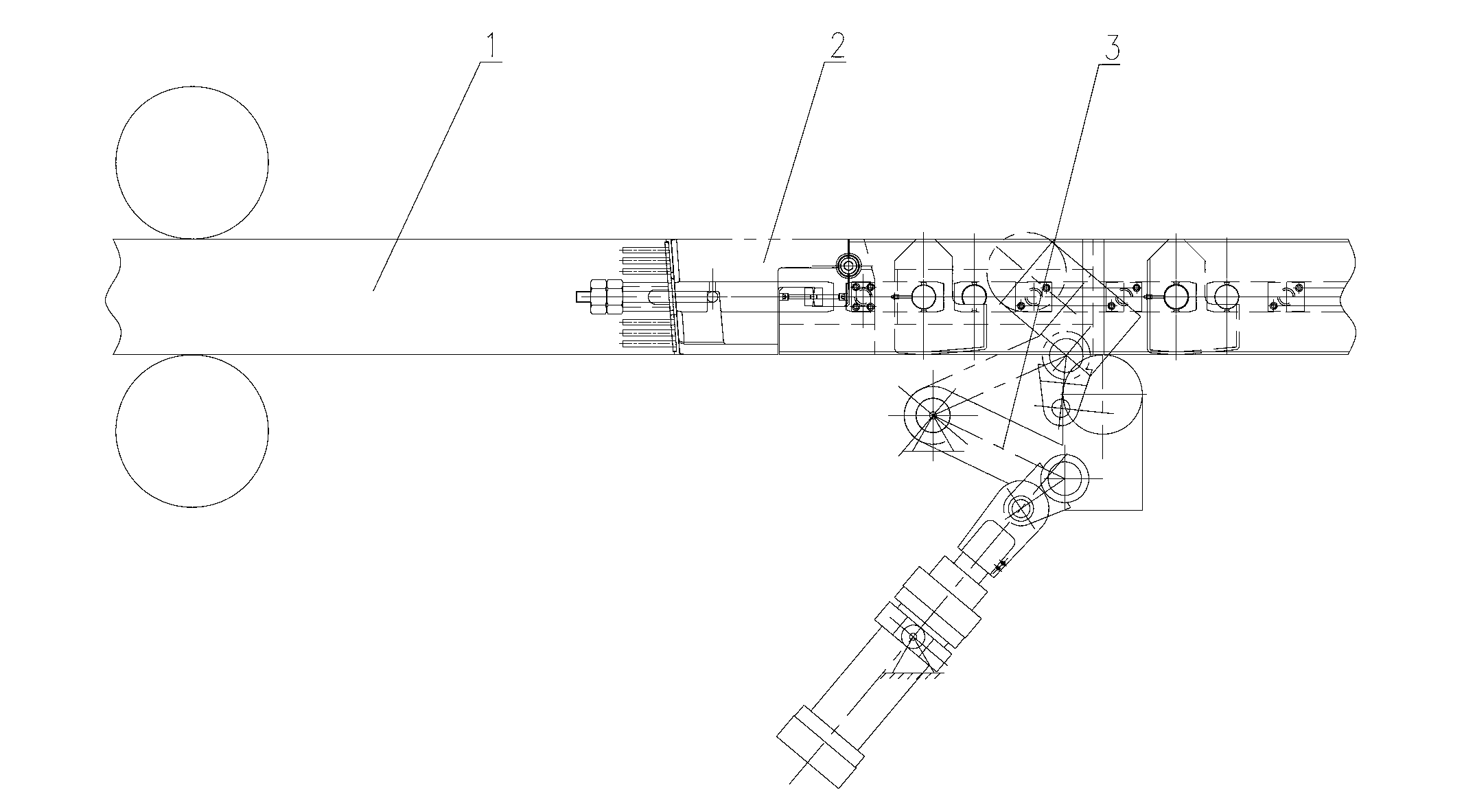

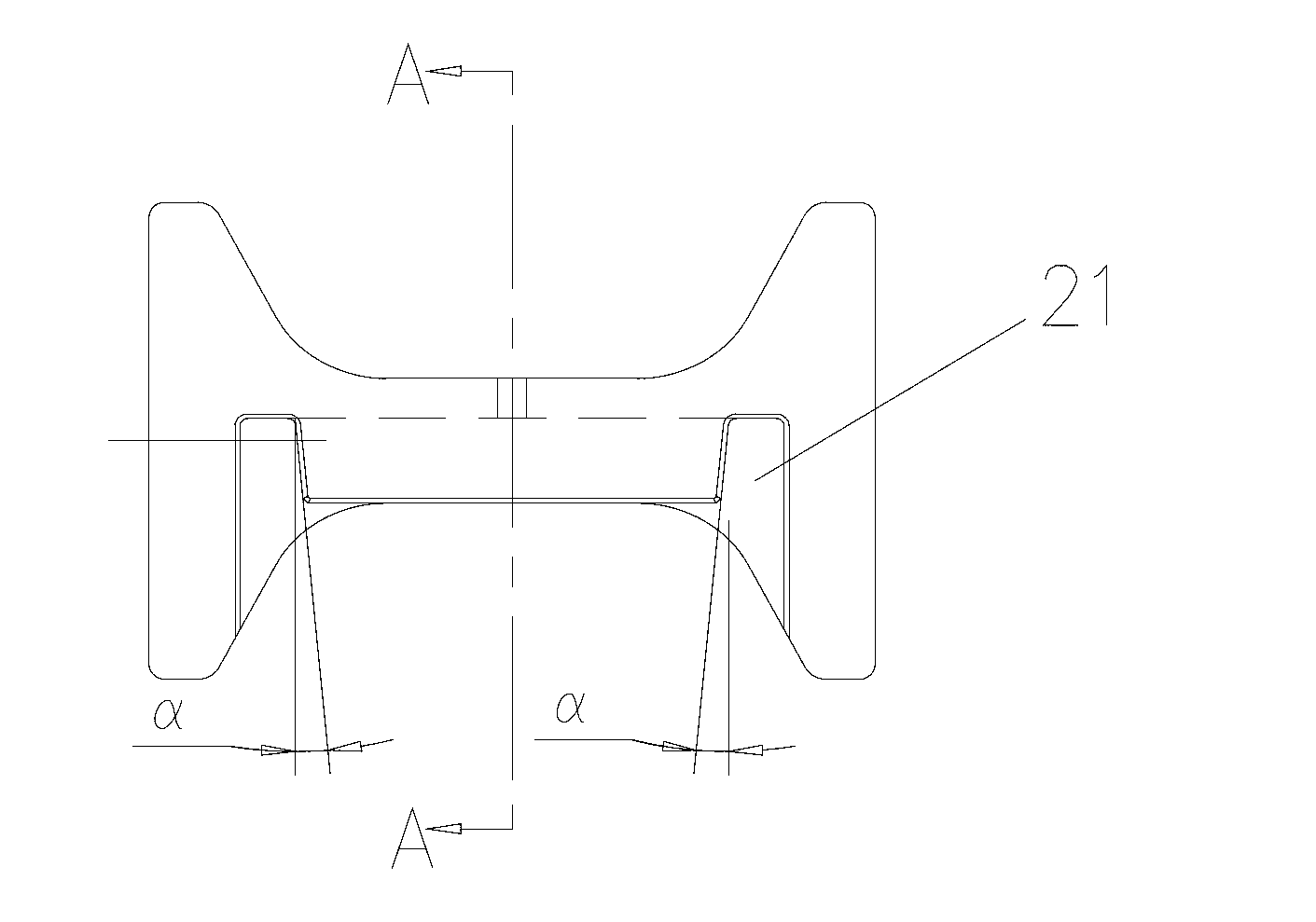

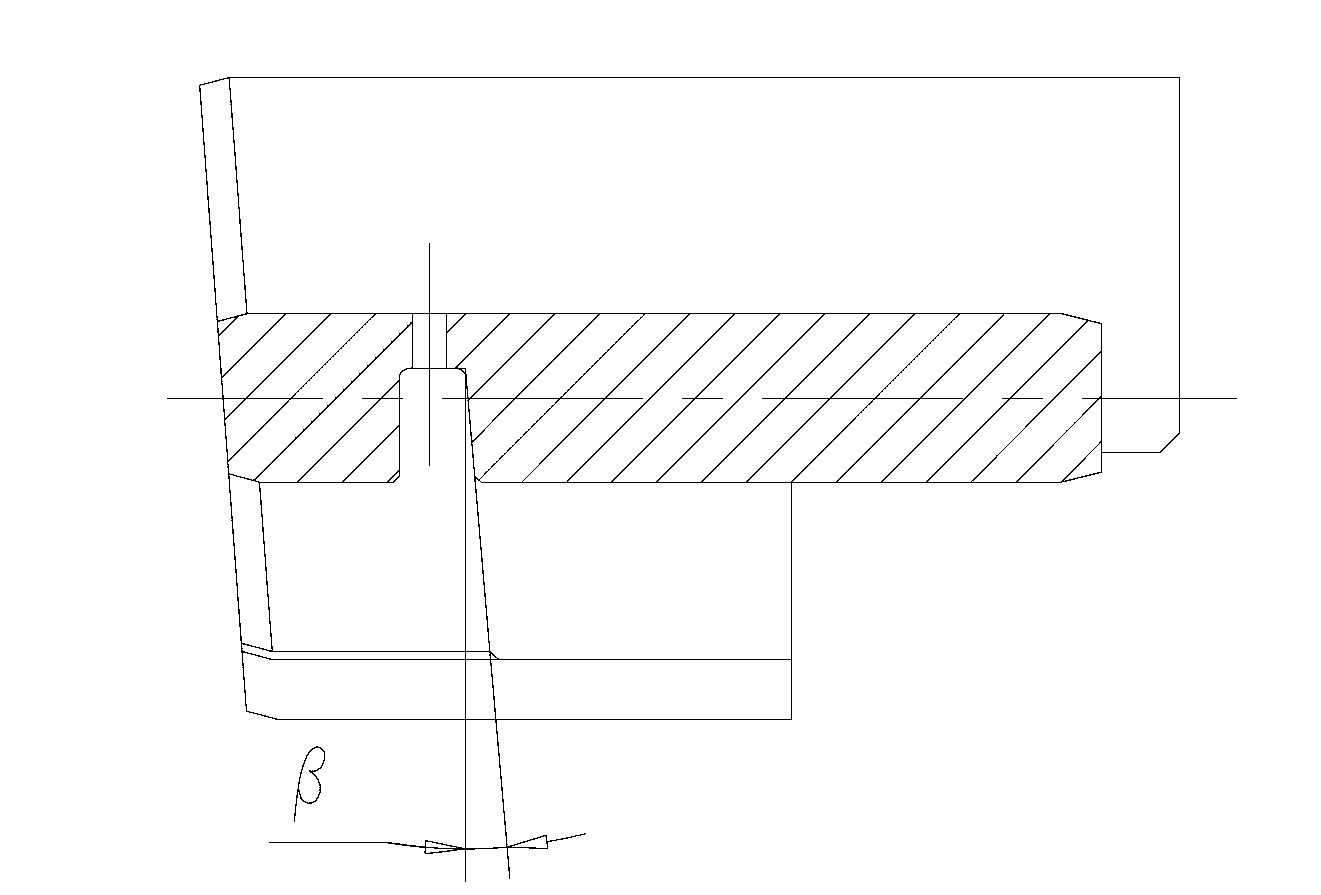

[0021] As shown in the figure, an online dummy removal device for an H-shaped billet continuous casting machine includes a dummy removal ejector rod 3, a protective plate 4, a fixed rod 5, and a dummy rod 2 connected to a billet 1, the dummy rod The end of the rod 2 in contact with the slab is provided with a limiting groove 21, one end of the fixing rod is placed in the limiting groove, and the other end is fixed on the protective plate, and the protective plate is fixed on the dummy bar through the fixing rod.

[0022] In this embodiment, the separation of the dummy rod 2 from the billet 1 can be realized only by raising and lowering the dummy rod 3, which is greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com