Testing machine for detecting child tricycle falling performance

A technology for testing machines and baby carriages, which is applied in impact testing, testing of machine/structural components, measuring devices, etc., and can solve problems affecting the accuracy of test results and defects in children's tricycle drop detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

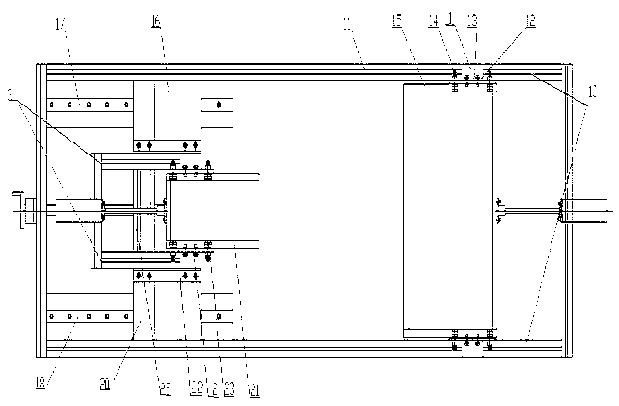

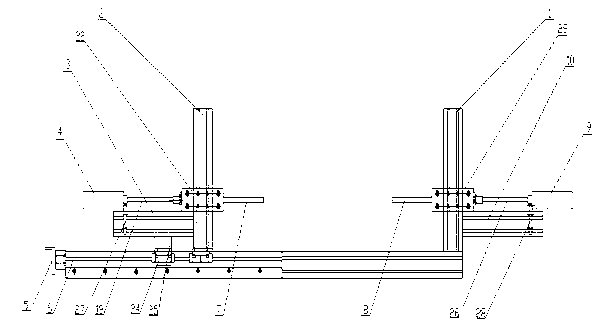

[0016] see figure 1 and figure 2 , the baby carriage drop performance testing machine includes a bottom frame (11), a front wheel disengagement mechanism, a rear wheel disengagement mechanism, a baby carriage front wheel support plate (7), a baby carriage rear wheel support plate (8), and is characterized in that: the bottom frame (11 ) right end is connected with a right vertical aluminum profile (1), and the left end of the bottom frame (11) is connected with a left vertical aluminum profile (2) through a screw and a nut; the right vertical aluminum profile (1) and the left The middle part of the vertical aluminum profile (2) is respectively connected with the rear wheel disengagement mechanism and the front wheel disengagement mechanism through the right horizontal aluminum profile (10) and the left horizontal aluminum profile (3); the front wheel disengagement mechanism and the rear wheel disengagement mechanism The mechanism is connected with the baby carriage front whe...

Embodiment 2

[0018] The structure of the bottom frame (11) is: the upper surface is equipped with two linear guide rails (17, 18), and the guide rails (17, 18) are equipped with guide rail mounting plates (16, 20), and the guide rail mounting plates (16, 18) 20) are connected by an auxiliary beam (25). The hand wheel (5) drives the lead screw nut (24) through the lead screw (6), and the lead screw nut (24) is connected with the left horizontal aluminum profile (3) through the auxiliary beam (25). The rotating hand wheel (5) is transmitted to the driven screw nut (24) by the leading screw (6) to realize that the guide rail mounting plate (16, 20) moves along the direction of the linear guide rail (17, 18), and the moving distance is selected according to the size of the vehicle body.

[0019] The structures of the front wheel disengagement mechanism and the rear wheel disengagement mechanism are as follows: the front wheel disengagement mechanism is composed of a left cylinder (4) and a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com