Constraint type experiment supercavity generating device

A technology of generating device and supercavitation, which is used in measurement devices, fluid dynamics tests, instruments, etc., and can solve the problems of inability of scientific research institutions to conduct experiments, errors in the experimental results of ejection experiments, and inaccurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

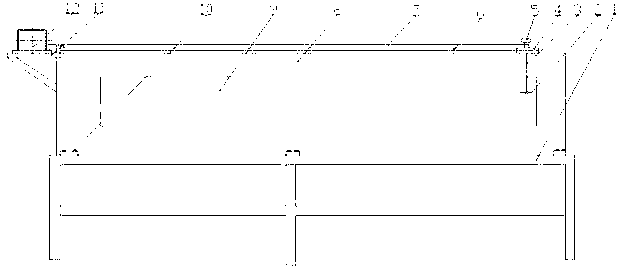

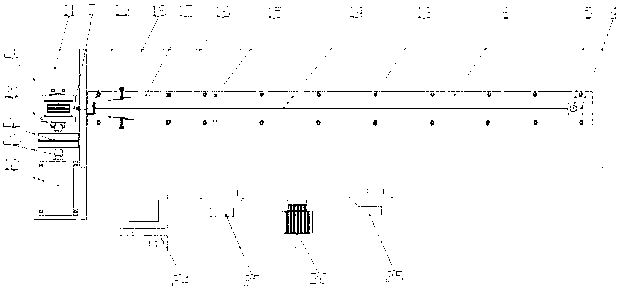

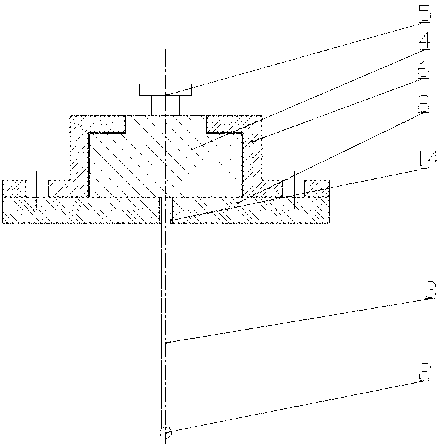

[0018] Such as figure 1 , figure 2 , image 3 As shown, in the present invention, the experimental water tank 8 is horizontally fixed on the experimental support 1 with bolts 10, and the front and back of the experimental water tank 8 are equipped with plexiglass windows 9, and two oppositely arranged "Z"-shaped guide rails 6 are fixed on the experimental water tank with screws 13. 8, along the middle of the length direction, there is a 4mm long through groove 14 on the top of the experimental water tank 8 along the length direction. One end of 3 is connected with the center of bearing slider 4, and the other end of connecting rod 3 passes through the experimental water tank 8 and extends into the experimental water tank 8 through the middle long through groove 14. The other end of connecting rod 3 is equipped with experimental model 2, steel wire One end of 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com