Patents

Literature

30results about How to "Intuitive and accurate measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

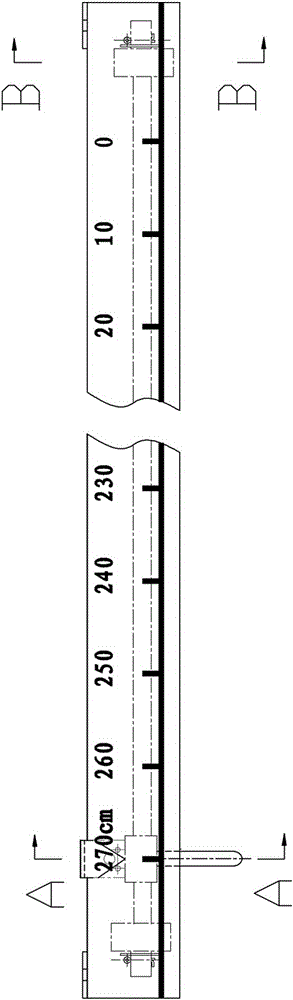

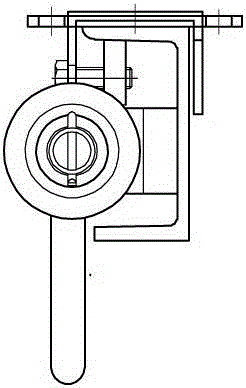

Constraint type experiment supercavity generating device

InactiveCN103257030AQuick and accurate disconnectionAccurately Stabilize CavitationHydrodynamic testingPressure sensorWater tanks

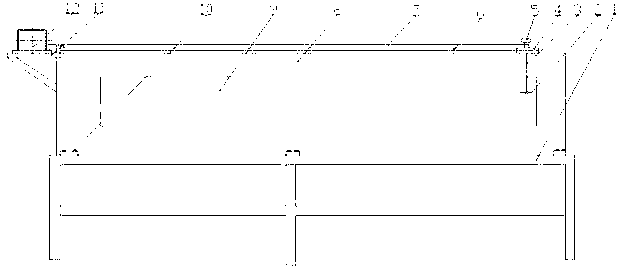

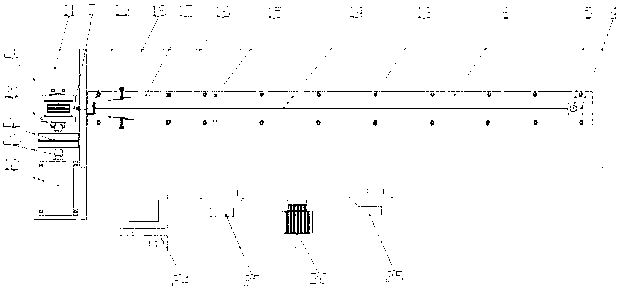

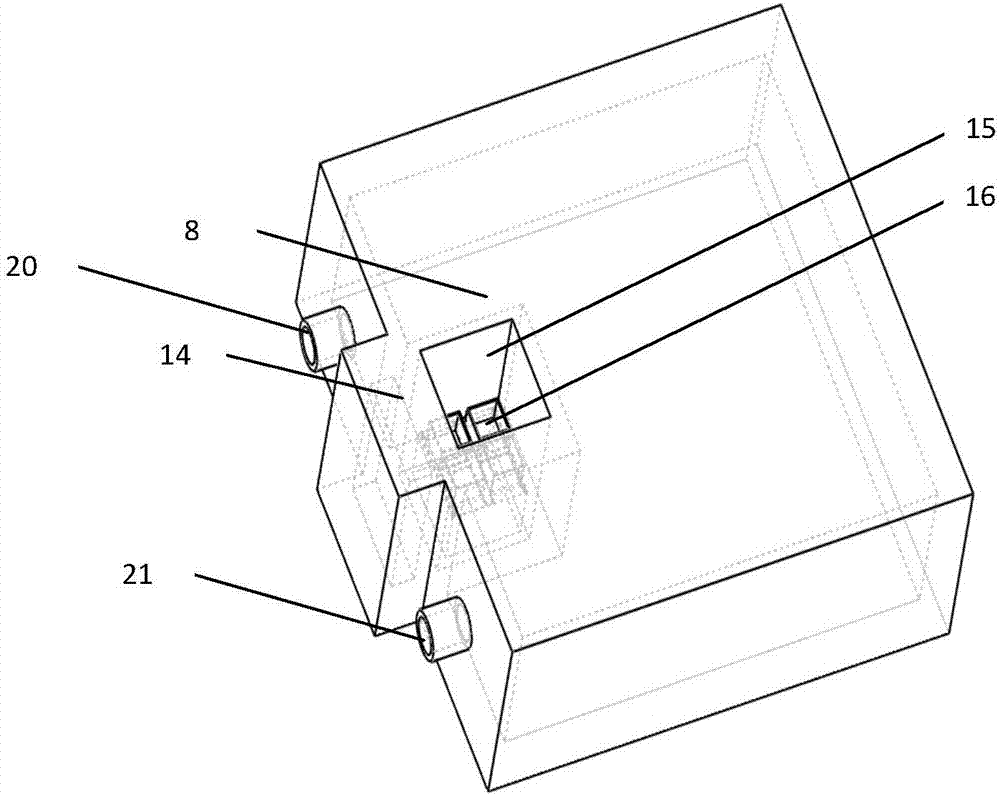

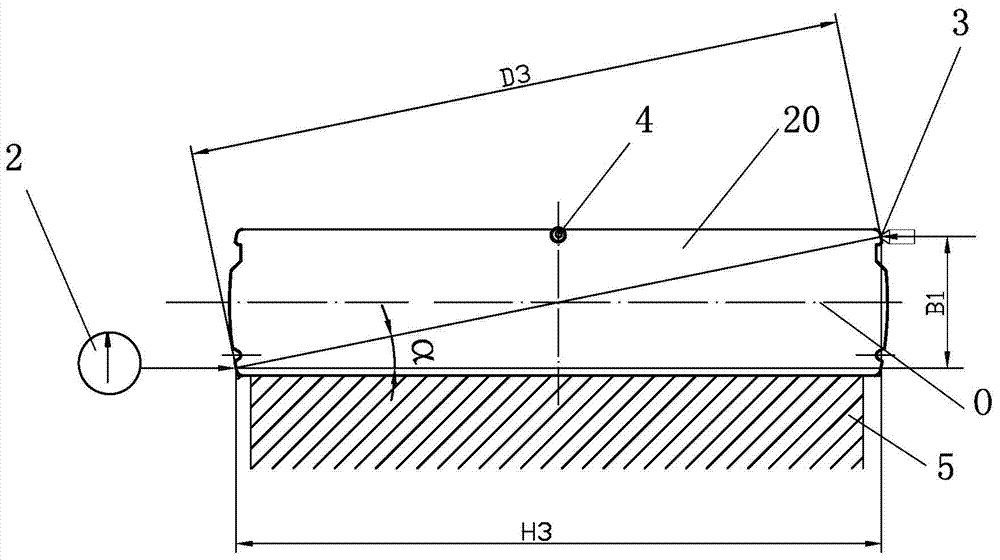

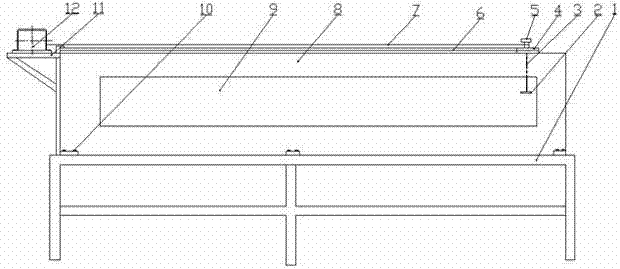

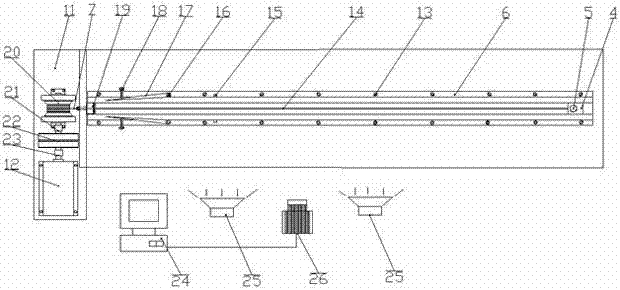

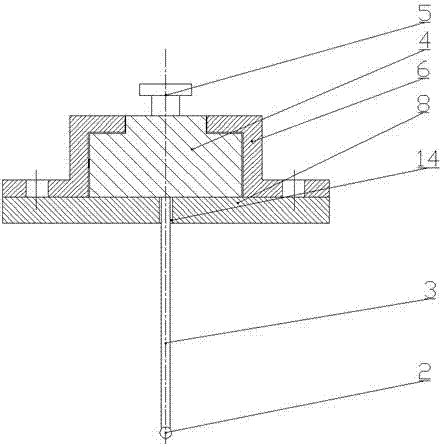

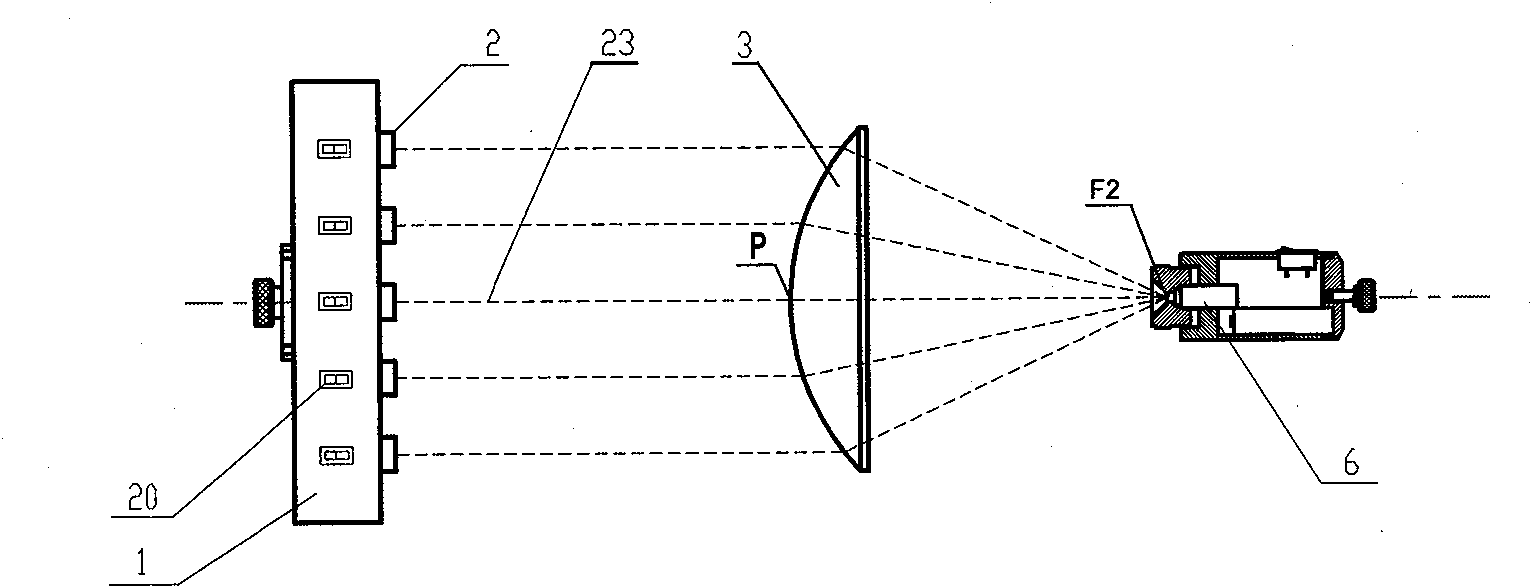

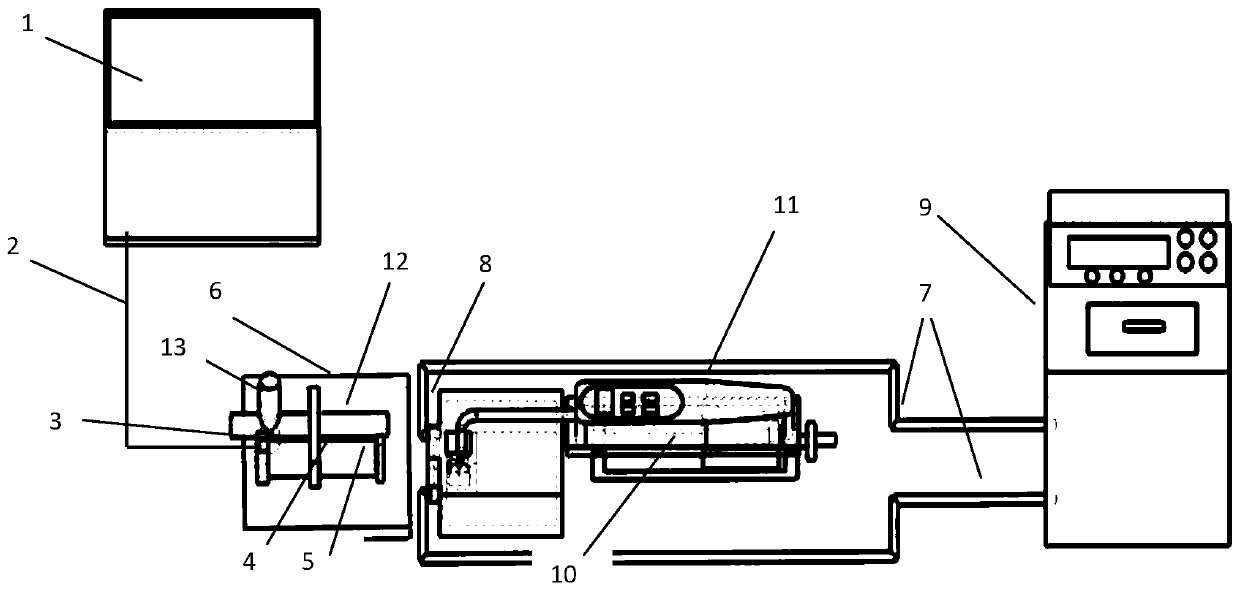

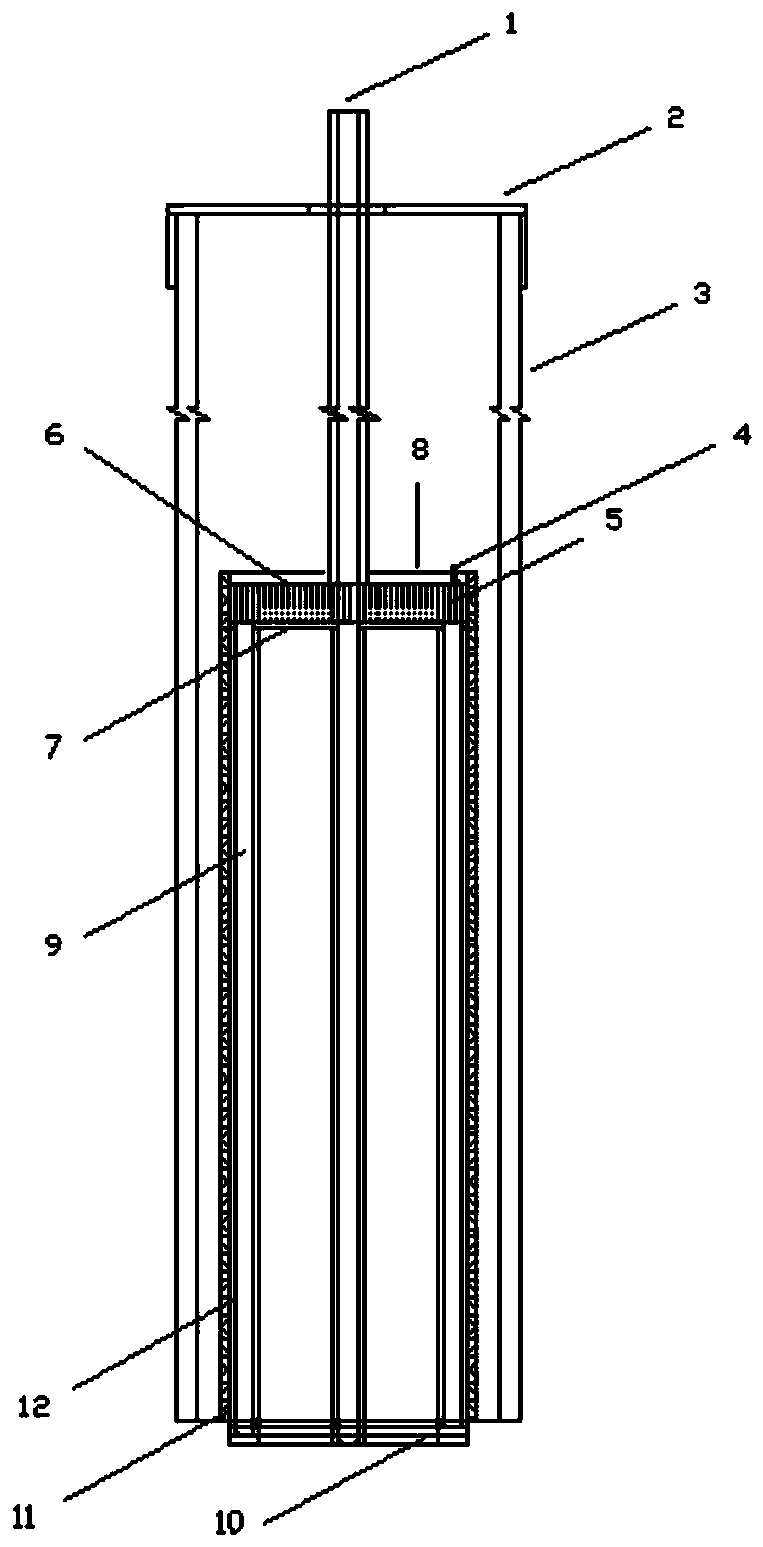

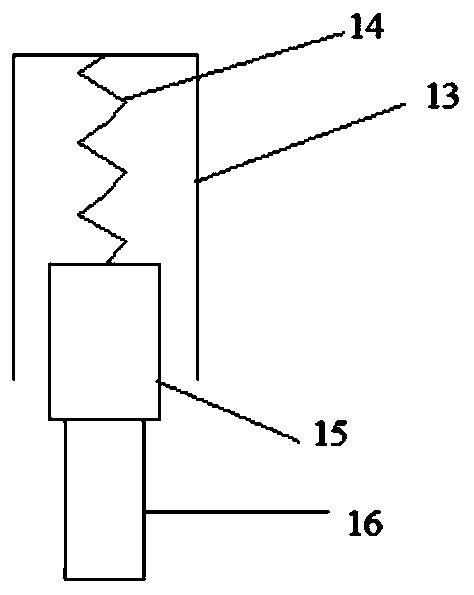

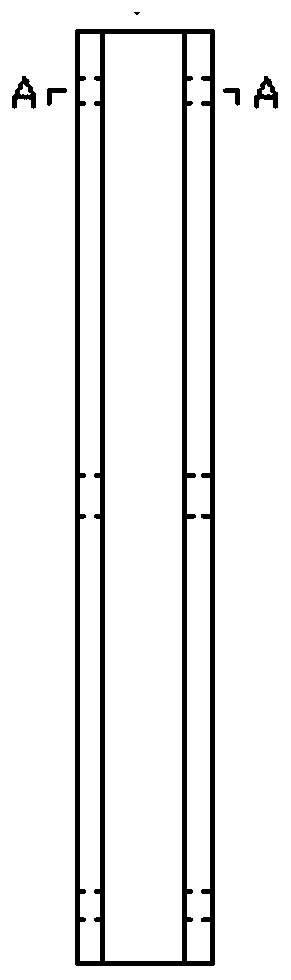

The invention discloses a constraint type experiment supercavity generating device. The front face and the rear face of a water tank are provided with organic glass windows. A through groove is formed in the middle of the upper face of the water tank in the length direction. Two Z-shaped guide rails which are oppositely arranged are installed on the water tank. A sliding pair is formed by a bearing sliding block and the guide rails. One end of a connecting rod is connected with the bearing sliding block and the other end of the connecting rod is provided with an experiment model which extends into the water tank. One end of a steel wire is connected with the bearing sliding block and the other end of the steel wire is connected with a winching wheel in a dragging device. The two guide rails close to one side of the dragging device are respectively provided with a sliding strip. A revolute pair is formed by one end of each sliding strip and one guide rail respectively through a rotary shaft. The side faces of the two guide rails are respectively provided with an adjusting screw. Two pressure sensors are arranged on the guide rails respectively. A high-speed camera and a lighting lamp are arranged in front of one window. The high-speed camera is connected with an industrial control computer. Supercavity generation and development processes around the experiment model are shot through the high-speed camera and accurate and stable experiment speed within a certain range is offered to different models.

Owner:ZHEJIANG SCI-TECH UNIV

Visual experiment device of wall adhesion mechanical properties of hydrate and working method of visual experiment device

ActiveCN107024428AEliminate conditionalityIntuitive and accurate measurementPreparing sample for investigationUsing mechanical meansAdhesion forceUnit system

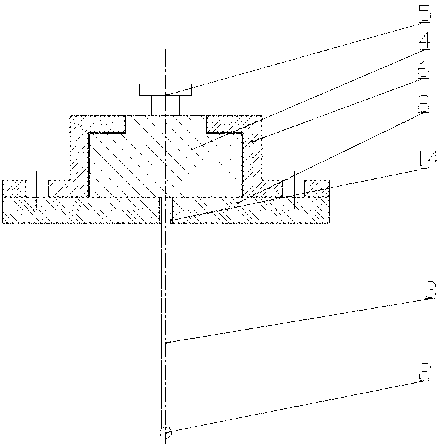

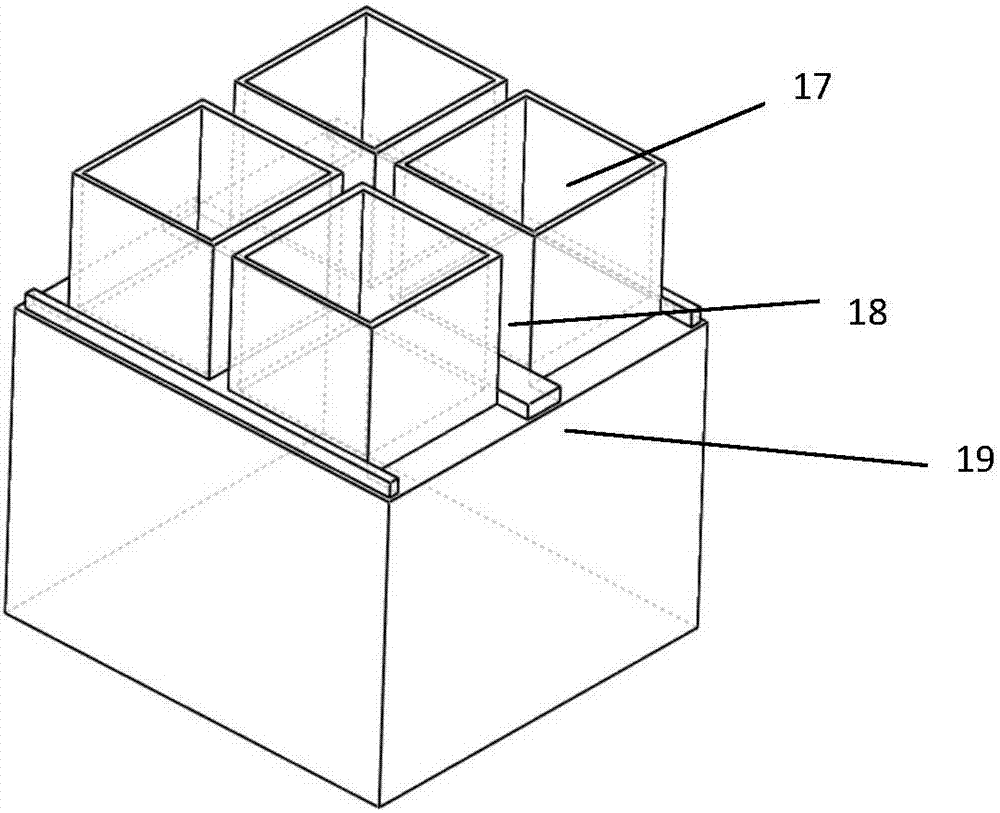

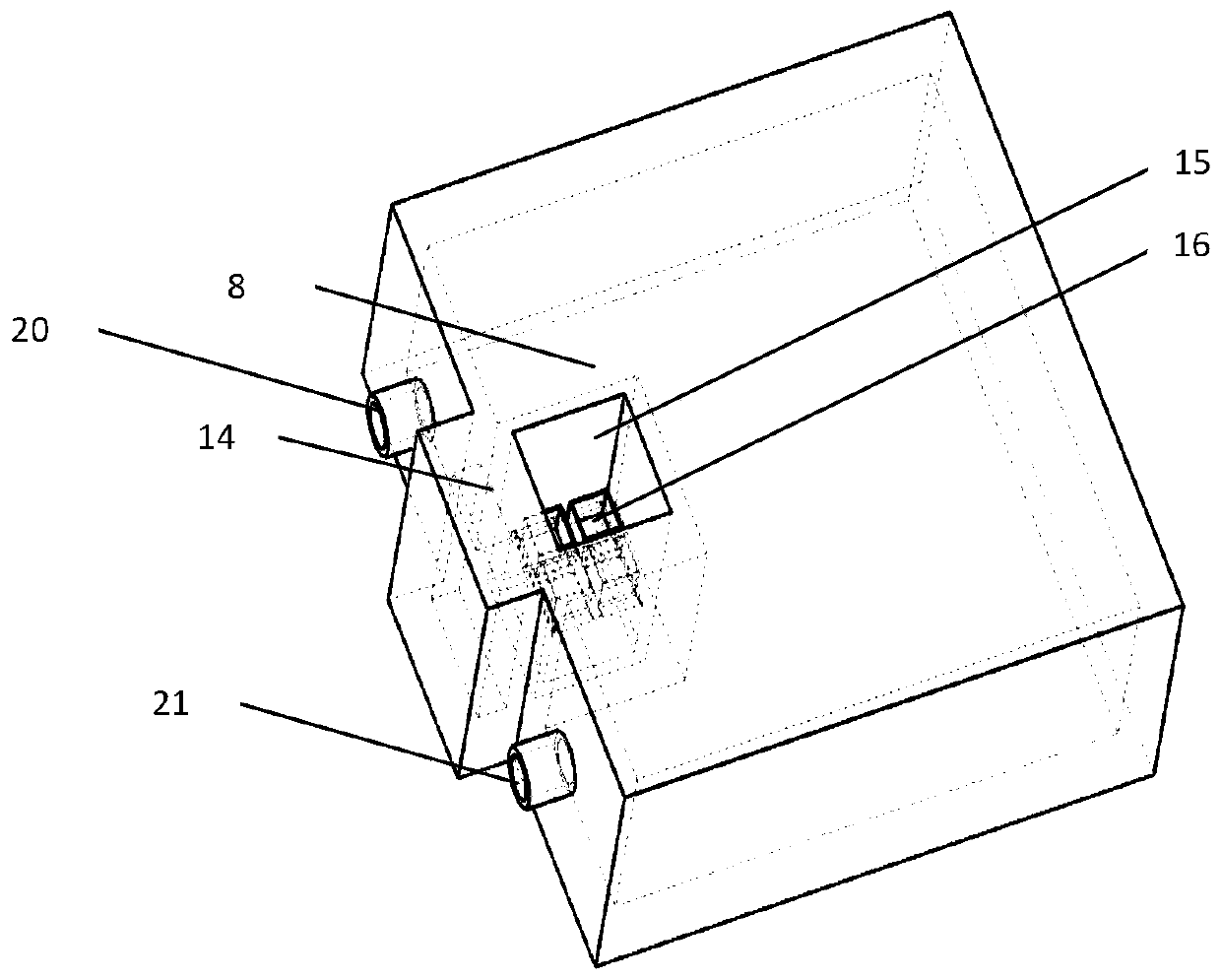

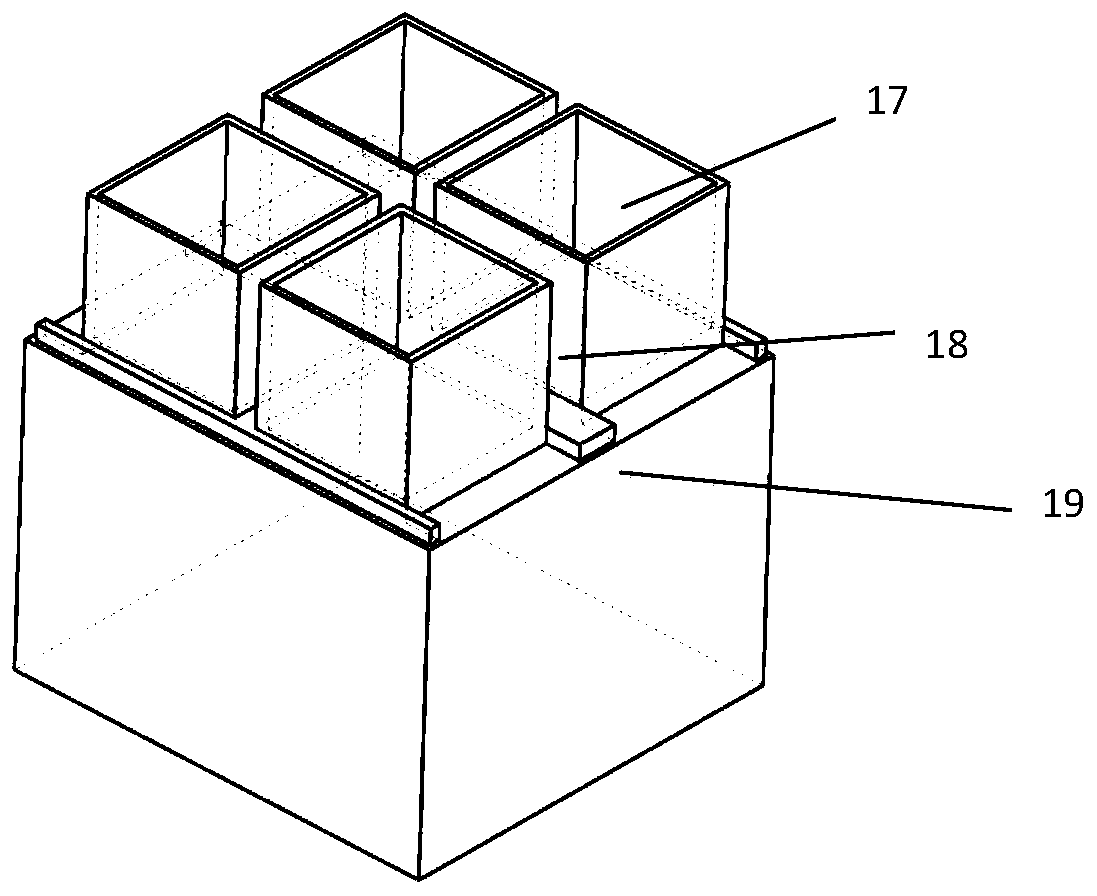

The invention relates to a visual experiment device of wall adhesion mechanical properties of hydrate and a working method of the visual experiment device. The visual experiment device comprises a circulating refrigeration system, a testing unit system, a microcosmic operation system and a microscopic observation system, wherein the testing unit system comprises a normal-pressure visual reaction device, a normal-pressure reaction groove, a liquid inlet, a liquid outlet and a testing unit element; the normal-pressure reaction groove is arranged on one side wall of the visual reaction device; the liquid inlet and the liquid outlet are formed in the side wall in a communicating manner; a visual window is further arranged on the side wall; the testing unit element is arranged in the normal-pressure reaction groove; the testing unit element comprises a solid metal block and transparent quartz frames; a plurality of transparent quartz frames are arranged on the solid metal block. By adopting the visual experiment device provided by the invention, generation, growth and deposition conditions of cyclopentane hydrate on a wall can be researched and monitored relatively well, and condition limitation that the hydrate only can be generated under a high-pressure environment is eliminated, so that an adhesion force of the cyclopentane hydrate generated on the wall is more accurately and directly measured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

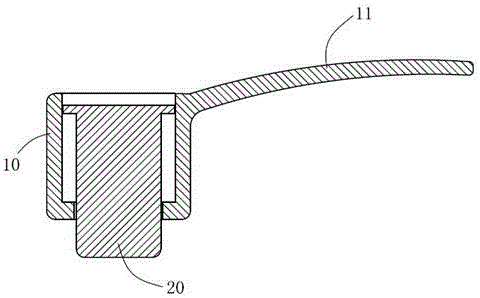

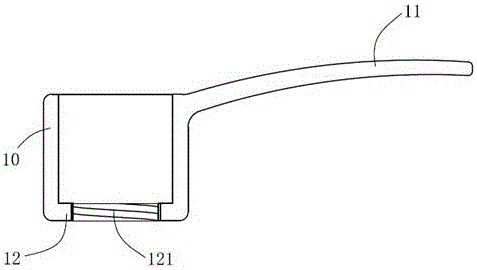

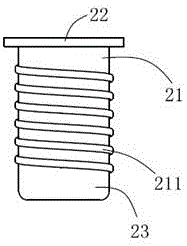

Salt spoon capable of accurately regulating dosage

ActiveCN105982486AIntuitive and accurate measurementReduce or expand volumeKitchen equipmentTablewaresInterference fitEngineering

The invention relates to a salt spoon capable of accurately regulating dosage. The salt spoon comprises a container cavity and a piston, wherein the container cavity is used for containing salt; the piston can be connected with the container cavity through interference fit and can move up and down along the inner wall of the container cavity to change the internal capacity of the container cavity. The salt spoon capable of accurately regulating dosage has the beneficial effects that by arranging the piston capable of moving up and down inside the container cavity and rotating the piston to move up and down along the container cavity to reduce or enlarge the capacity of the cavity, users can conveniently, intuitively and accurately measure the salt in required mass, thus the defect that existing spoons can not regulate the capacity is effectively overcome; the technical effect of being removable can be achieved between the container cavity and the piston, so the aim of facilitating washing can be achieved; the salt spoon capable of accurately regulating dosage has a simple structure, is ingenious in design, is convenient to use, enables the usage amount of the salt to be more accurate and is beneficial to human health.

Owner:HUIZHOU UNIV

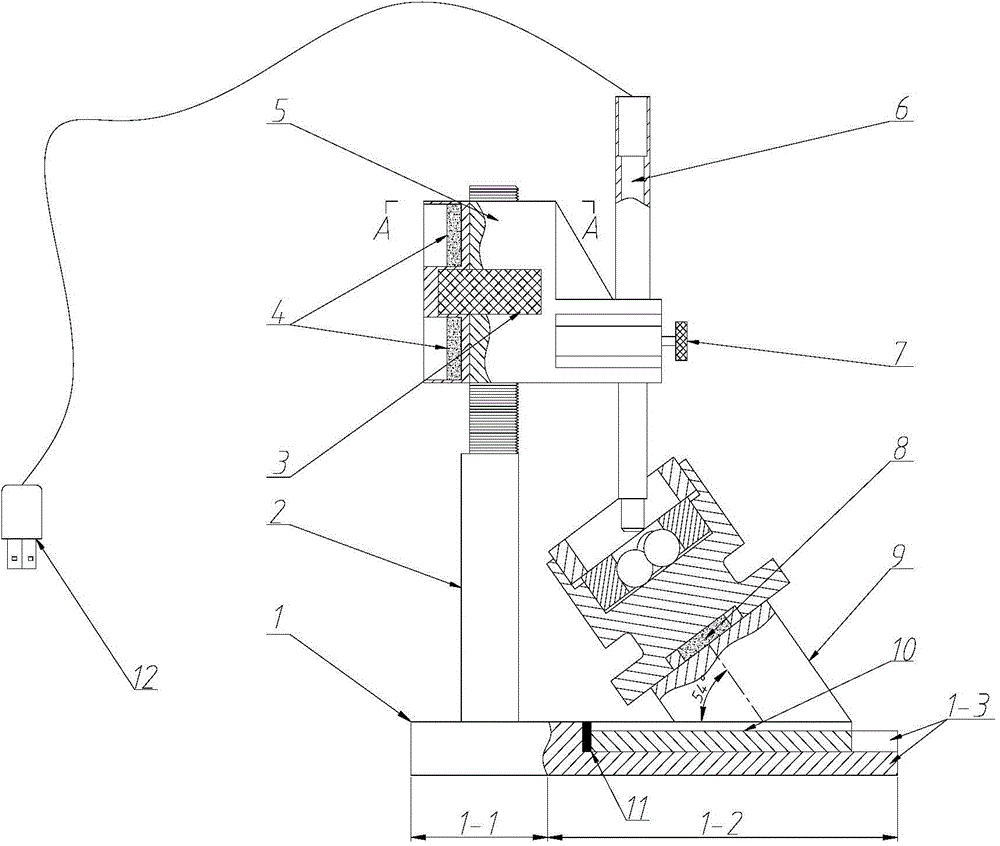

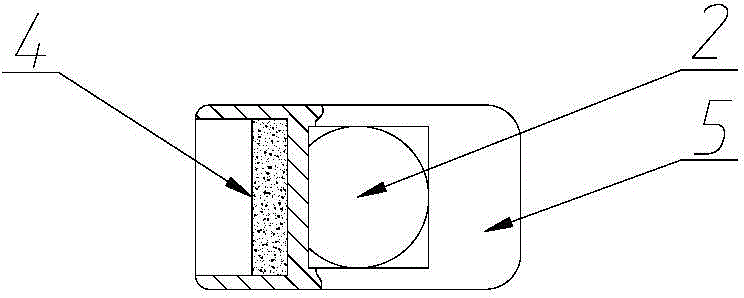

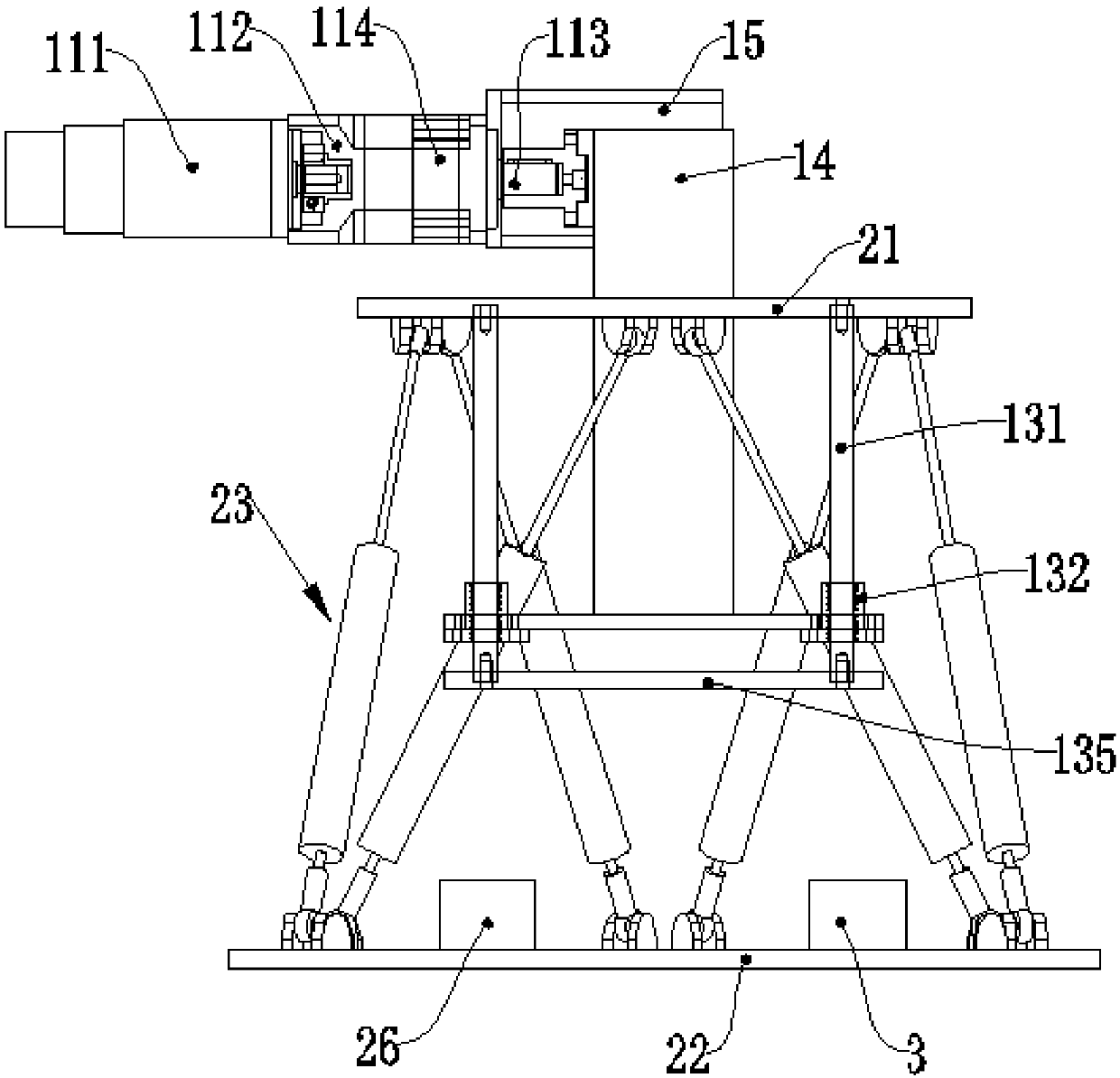

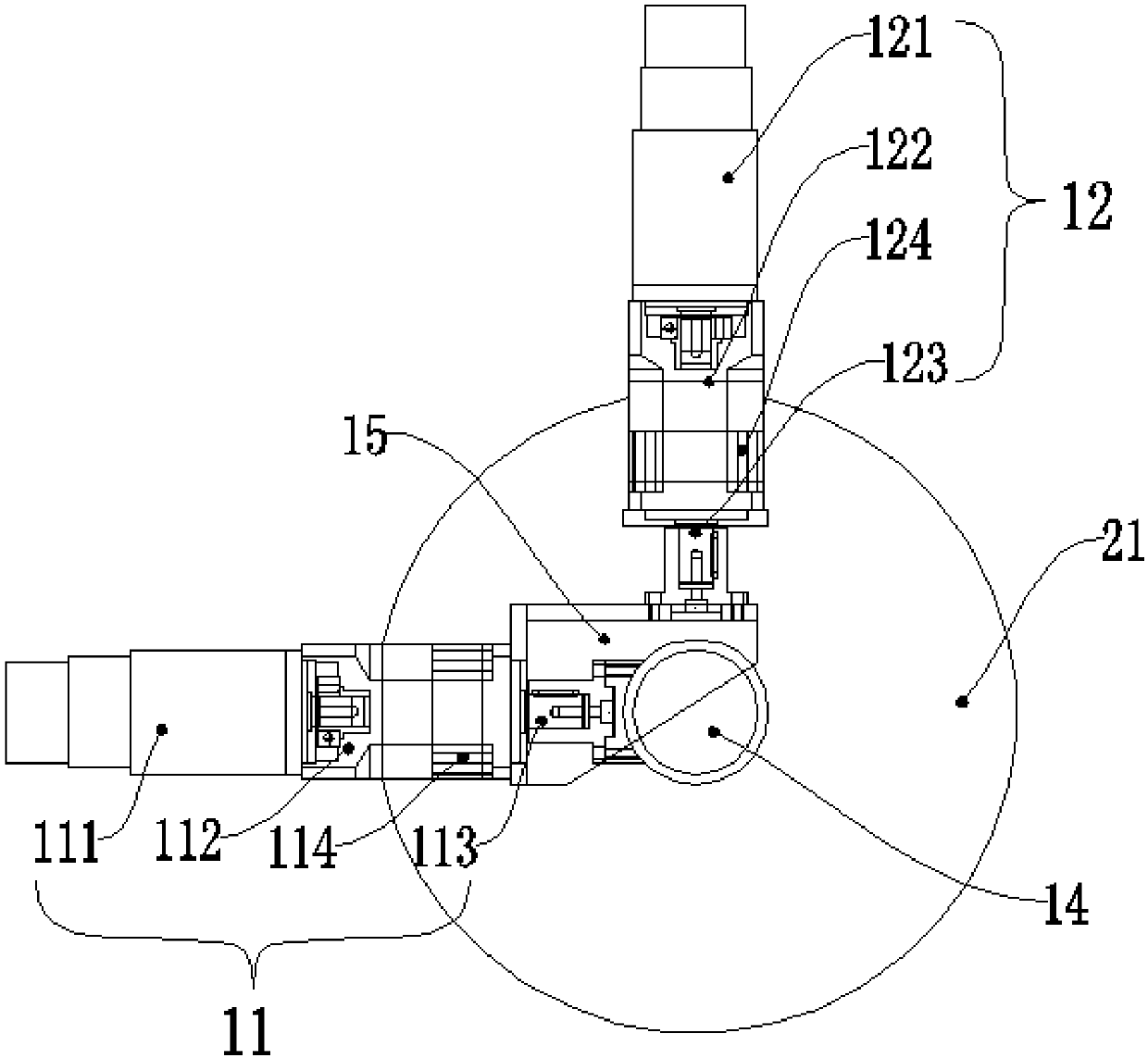

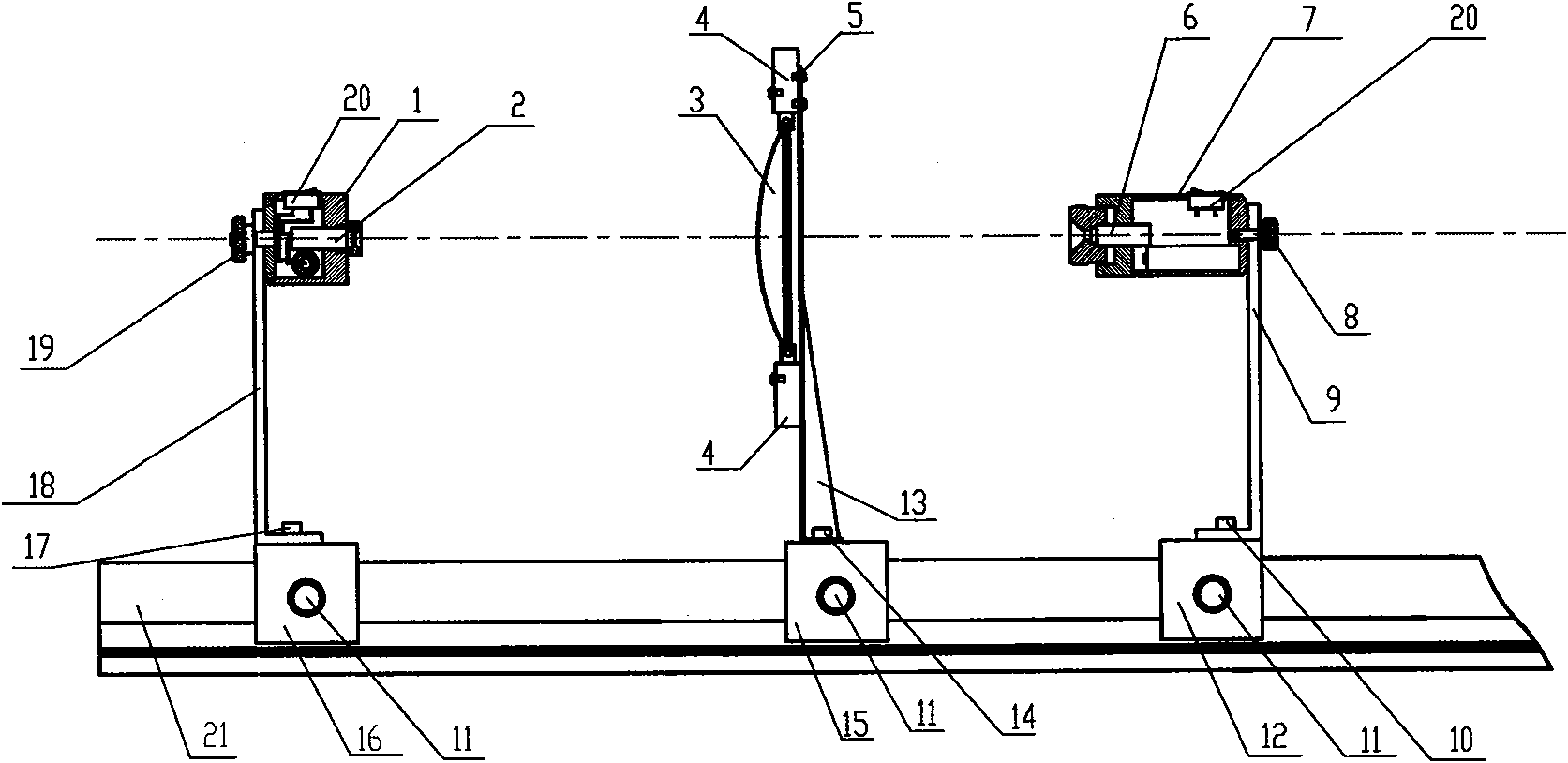

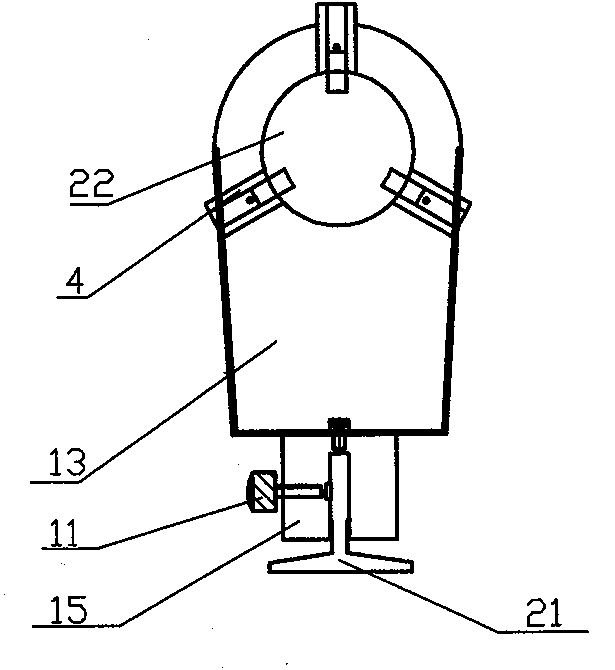

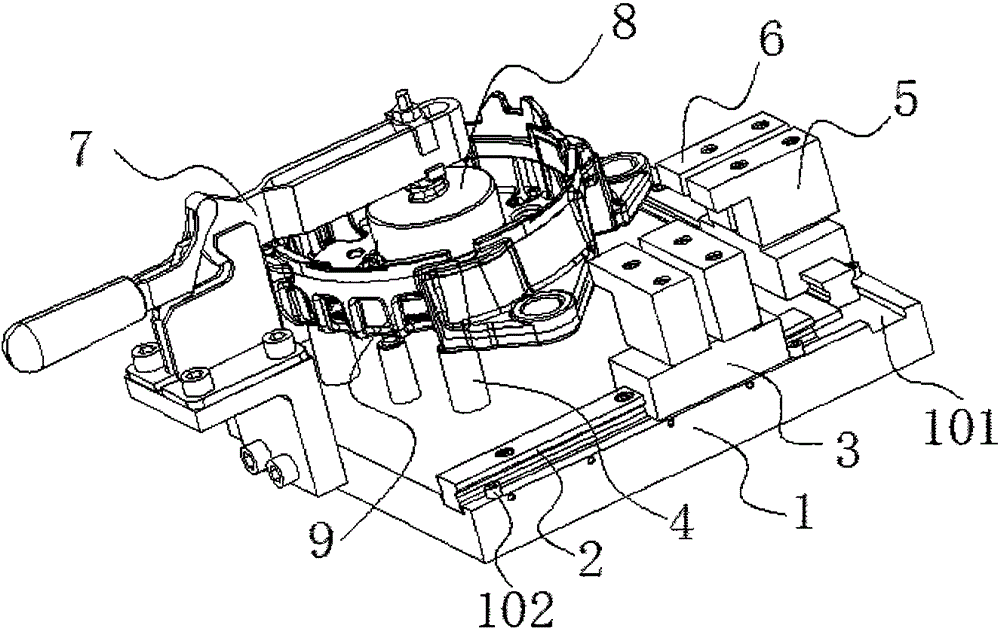

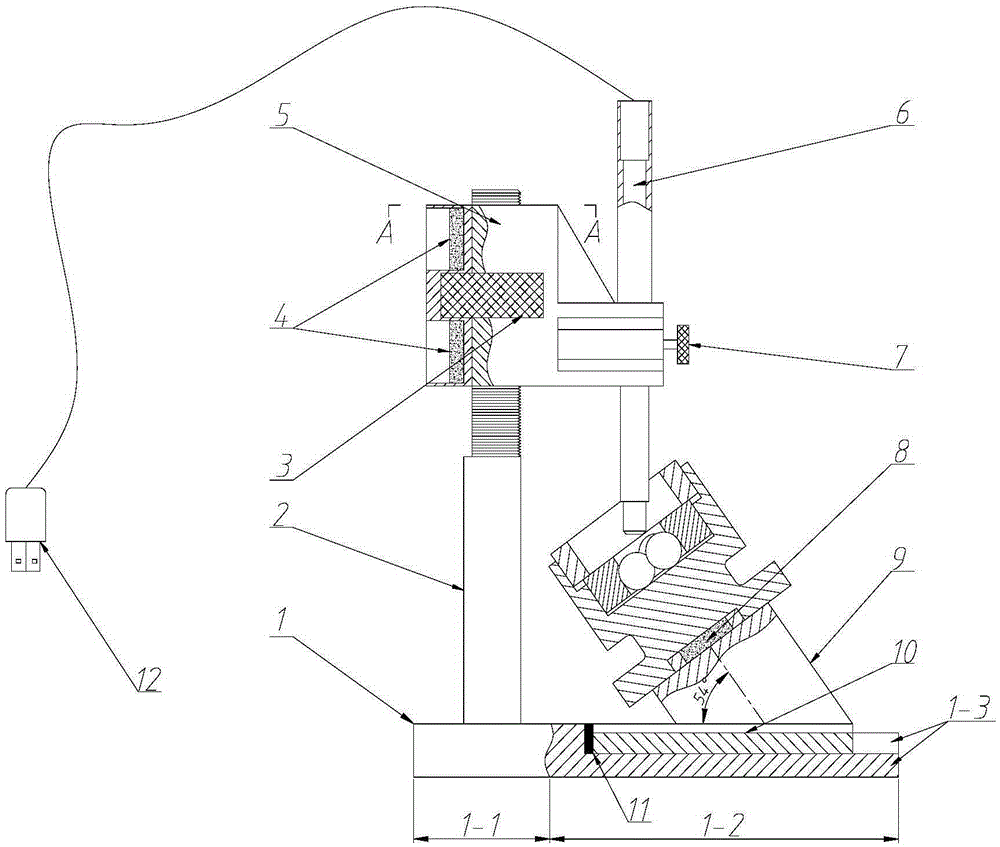

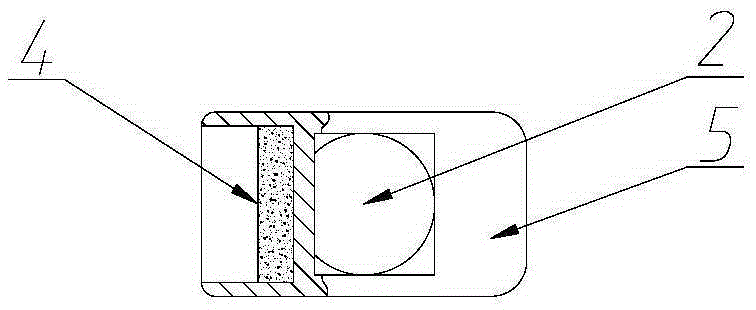

Digital microscope wear scar measurement device

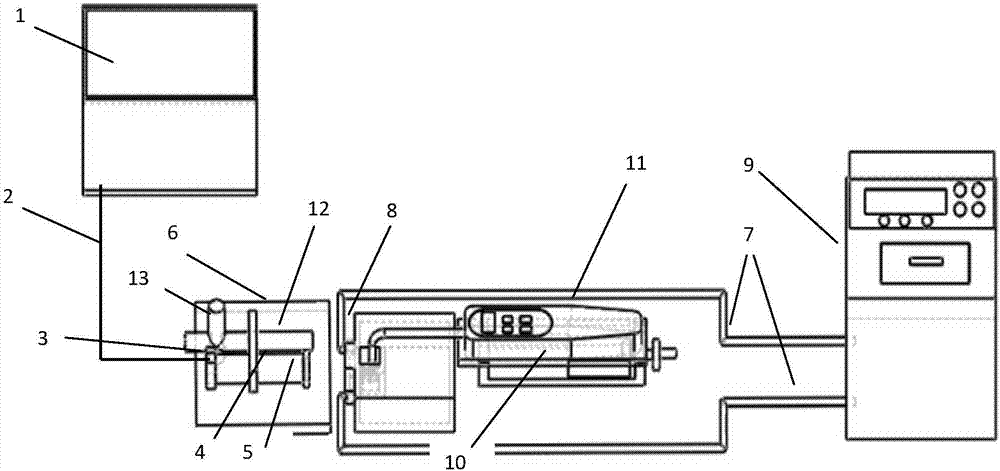

ActiveCN104020044AAvoid measurement errorsRealize integrationStrength propertiesMeasurement deviceOptical axis

The invention relates to a digital microscope wear scar measurement device and belongs to the field of four-ball friction testing machine detecting equipment. The digital microscope wear scar measurement device comprises a bottom plate seat, a supporting beam, a fine thread supporting rod, a working platform, a digital microscope and a cylinder oil box base, wherein the bottom plate seat is composed of a seat body and a bottom plate, and the working platform is matched with the bottom plate in a sliding manner and provided with a sliding limiting block; the cylinder oil box base is arranged on the working platform in a manner that the axial lead of the cylinder oil box base has an included angle of 54 degrees with the working platform; the fine thread supporting rod is fixedly connected with the seat body, and the lifting of the supporting beam is adjusted relative to the fine thread supporting rod through an embedded nut of the supporting beam; two strong magnet pieces are arranged in two counter bores in one side in the supporting beam; the optical axis of the digital microscope has an included angle of 36 degrees with the axis of the cylinder oil box base, and the digital microscope is vertically connected to a connecting arm of the supporting beam. The digital microscope wear scar measurement device ensures the accurate centering and high-precision fine-tuning focal length of the working platform and provides quick and accurate observation and measurement for the wear scar detection of four-ball friction testing machines.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

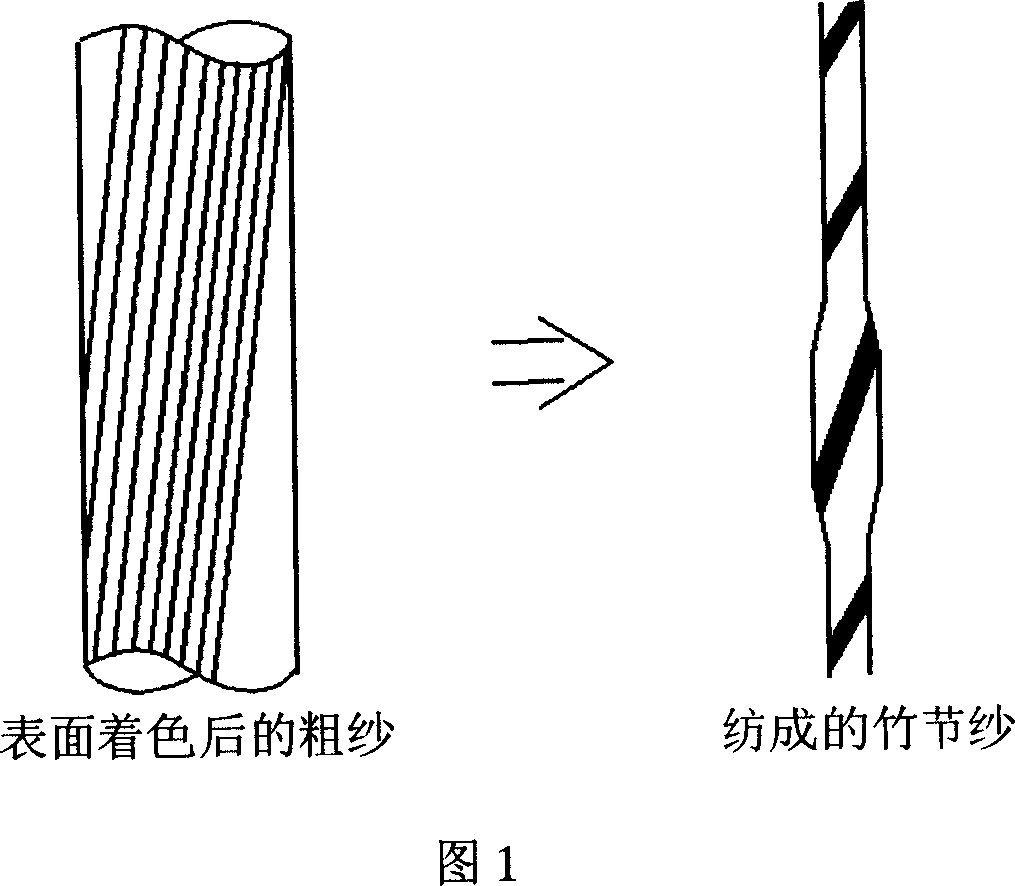

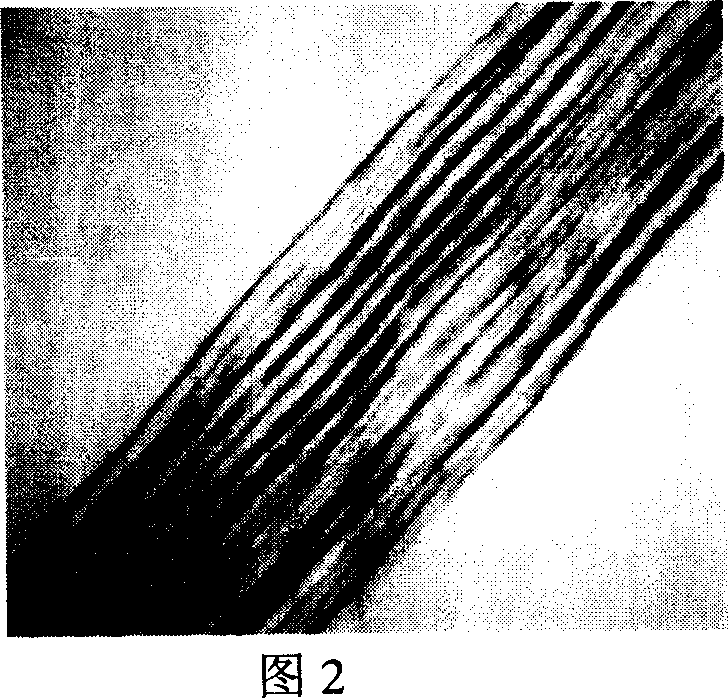

Method of measuring the twist angle between slub and base yarn of slub yarn

InactiveCN1974897ATowards Intuitive and ClearAccurate measurementUsing optical meansTextiles and paperYarnFiber

The combined fiber tracer method and image method for measuring the twist angles of different parts of bunchy yarn. The roving is first surface dyed to reach the bunchy yarn spinning effect similar to that of two kind of roving in different colors; and the spun bunchy yarn is then wound onto one deep color paper board in certain tension for easy measurement. The images capable of showing the fiber trend in the yarn surface are obtained with DZ3 type microscope and image acquiring software and processed with image processing software to measure the twist angles of different sections of bunchy yarn.

Owner:JIANGNAN UNIV

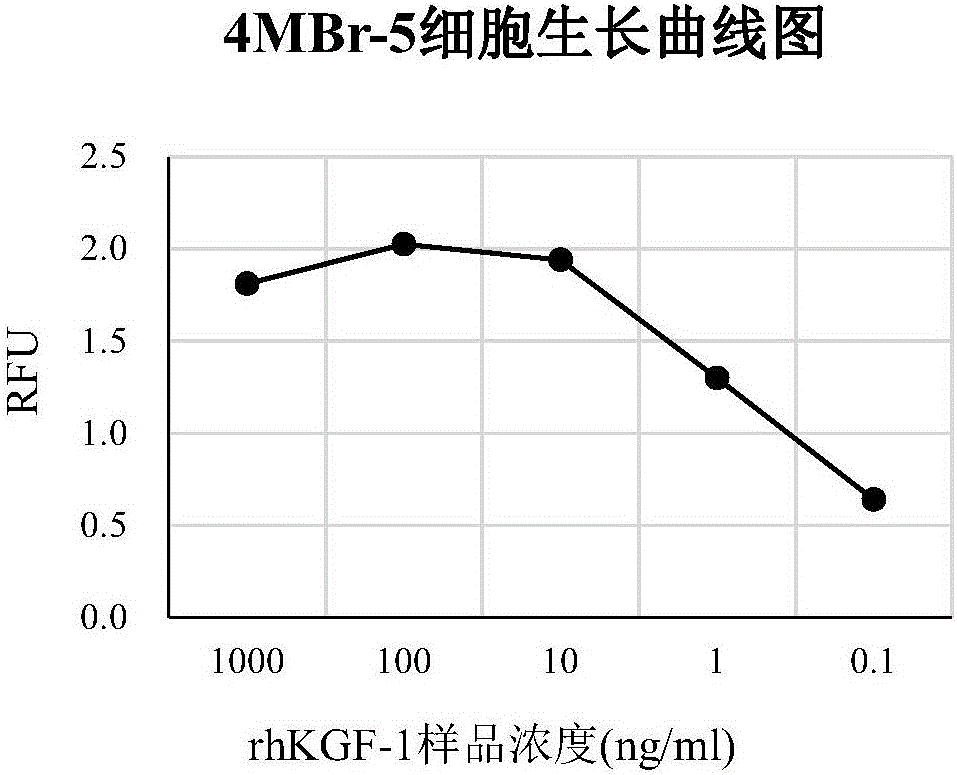

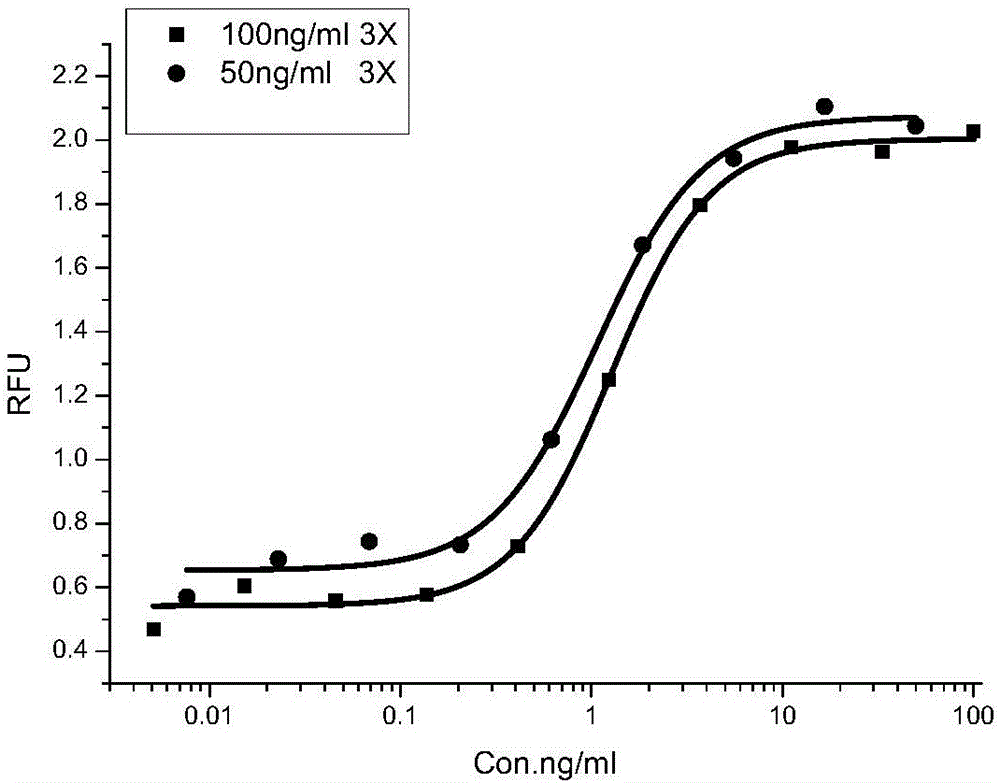

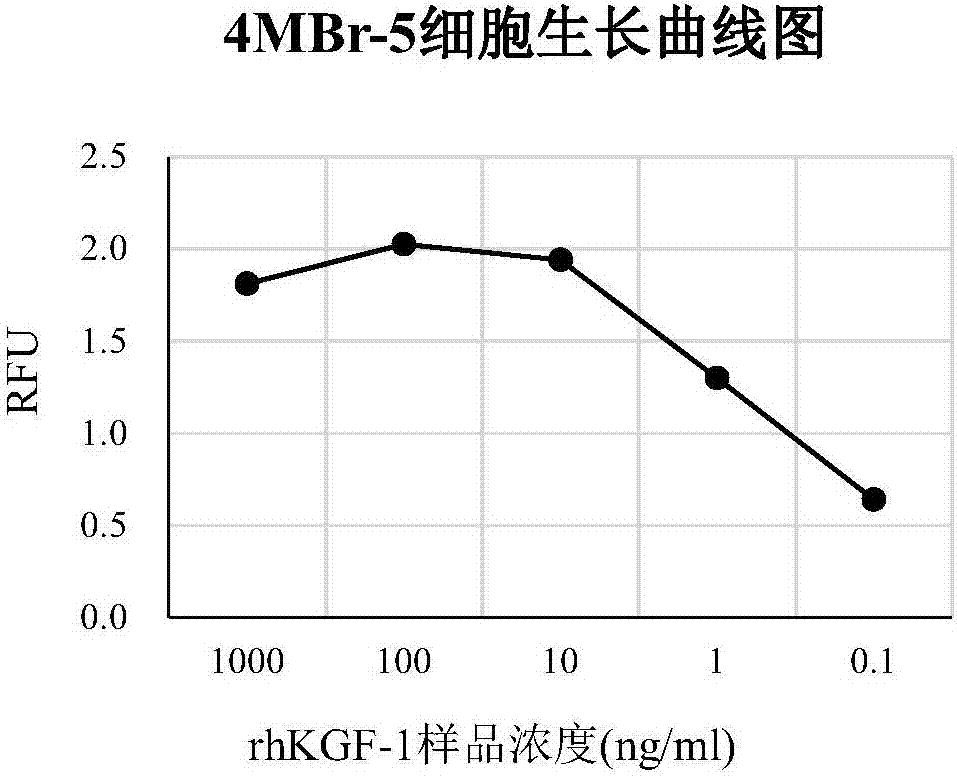

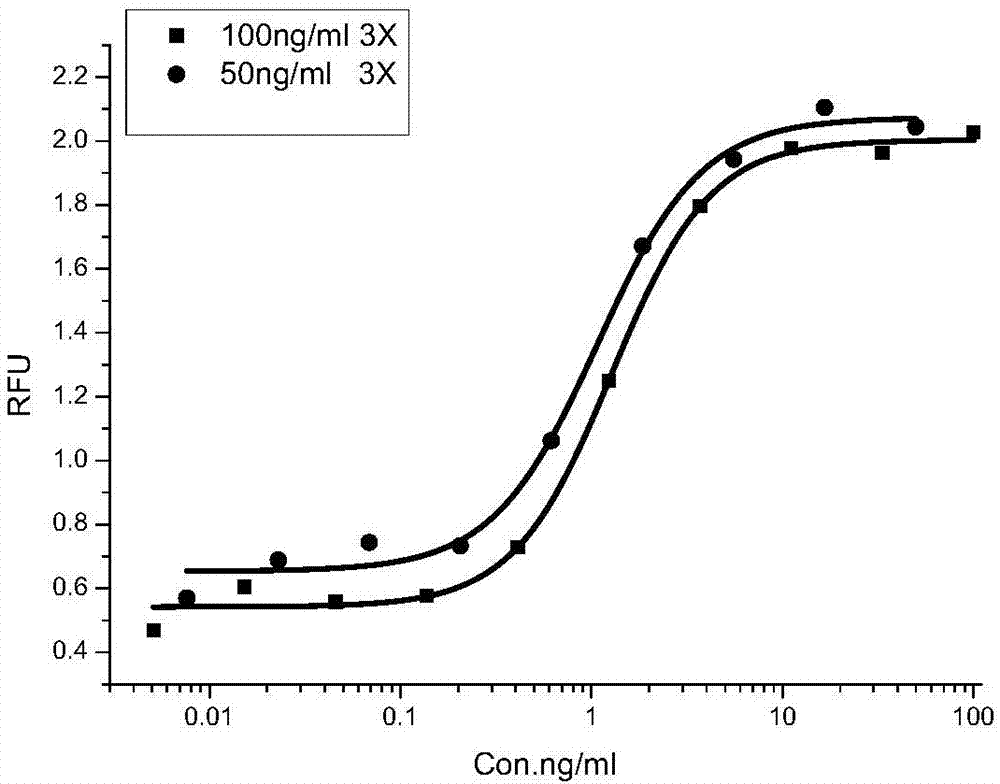

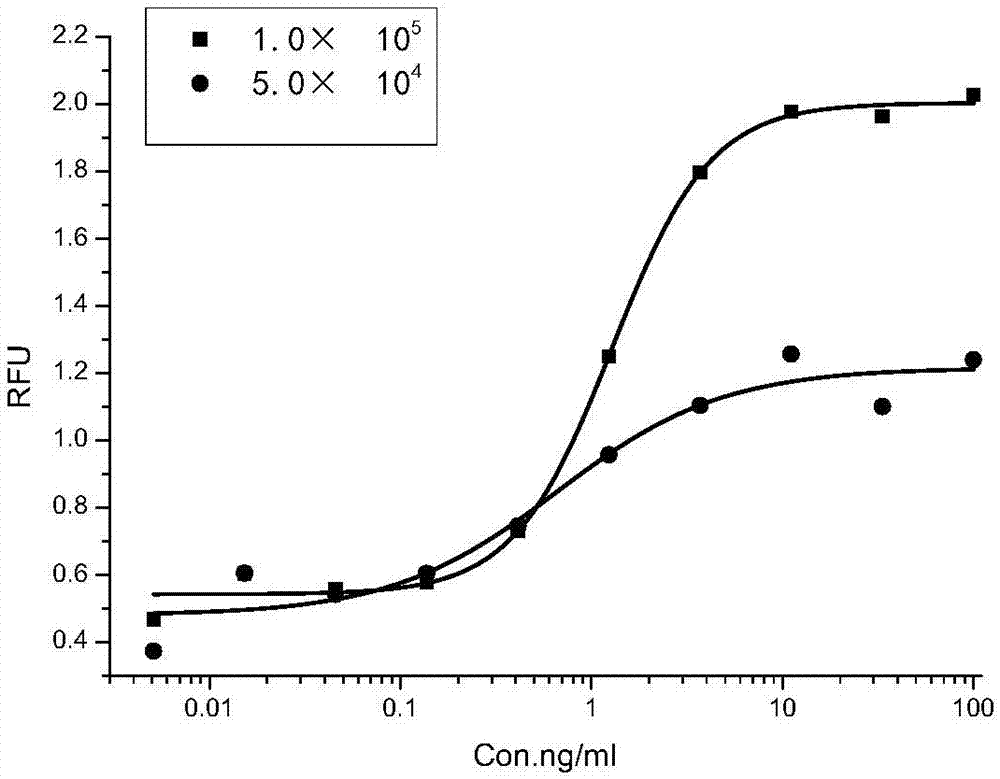

Method for detecting biological activity of recombinant human keratinocyte growth factors

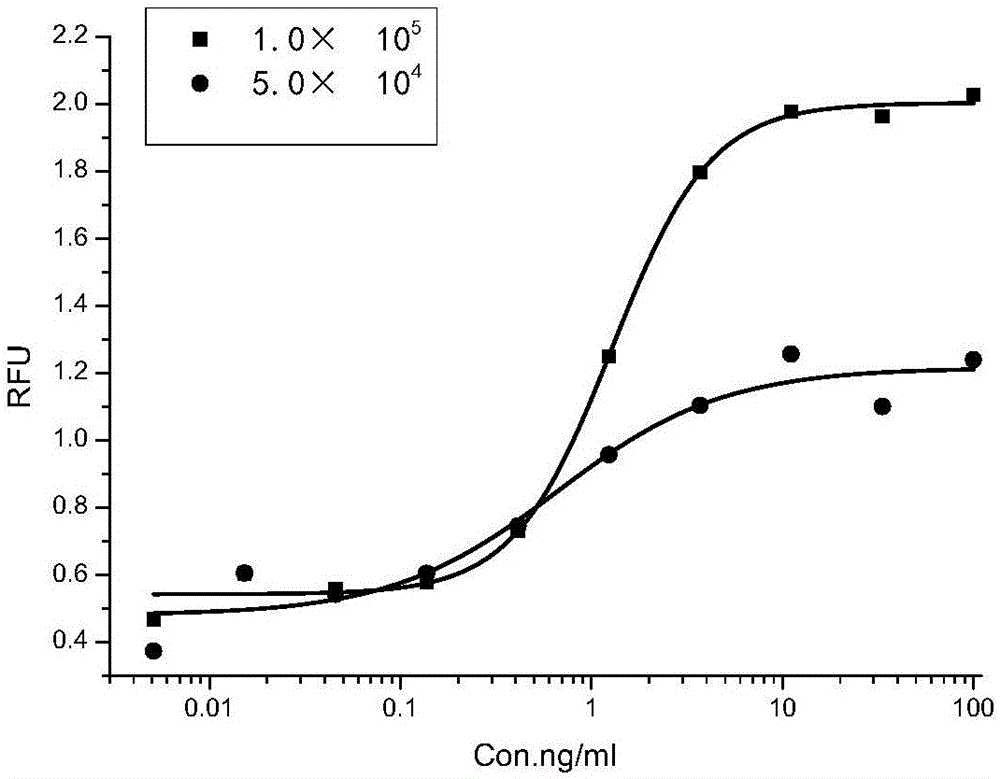

ActiveCN106226511APromote proliferationIntuitive and accurate measurementBiological testingRecombinant Human Keratinocyte Growth FactorVolumetric Mass Density

The invention provides a method for detecting recombinant human keratinocyte growth factors (rhKGF-1). The method includes steps of 1), cultivating keratinocytes; 2) inoculating the keratinocytes and controlling the density of the keratinocytes; 3), treating rhKGF-1 samples, carrying gradient dilution on the concentration of the rhKGF-1 samples and adding 5-acetenyl-2'-deoxyuridine (EdU) into the rhKGF-1 samples with various rhKGF-1 concentration dilution degrees to prepare loading samples with the series of rhKGF-1 concentration dilution degrees; 4), washing the keratinocytes in keratinocyte plates obtained at the step 2) and removing cultivation media; 5), loading the loading samples obtained at the step 3) into keratinocyte cultivation plates obtained at the step 4) and cultivating and incubating the keratinocytes; 6), solidifying and permeabilizing the keratinocytes, and then carrying out 'Click-iT' reaction on the EdU; 7), arranging the keratinocytes treated at the step 6) in a multifunctional microplate reader, reading the fluorescence intensity (RFU) and computing the biological activity of the rhKGF-1. The method has the advantages of low detection background, high sensitivity, specificity and accuracy, good repeatability and the like. Besides, the method is particularly applicable to detecting the biological activity of the rhKGF-1 and establishing quality standards.

Owner:信立泰(苏州)药业有限公司

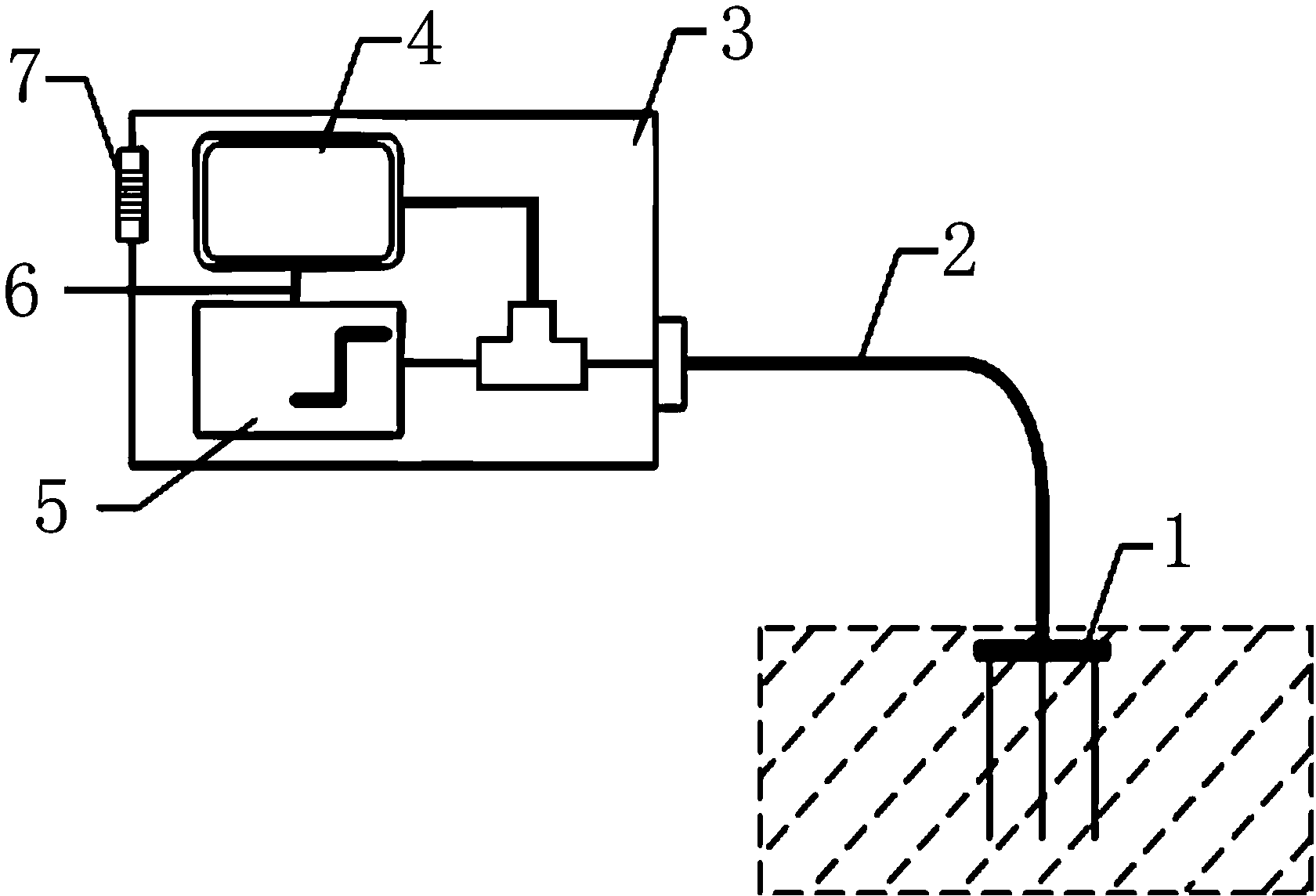

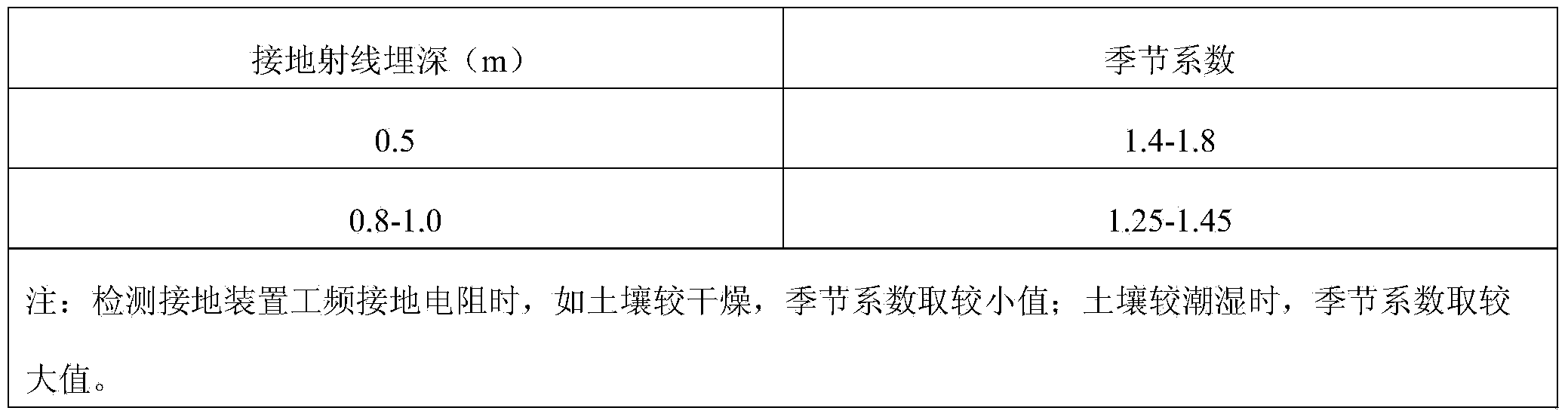

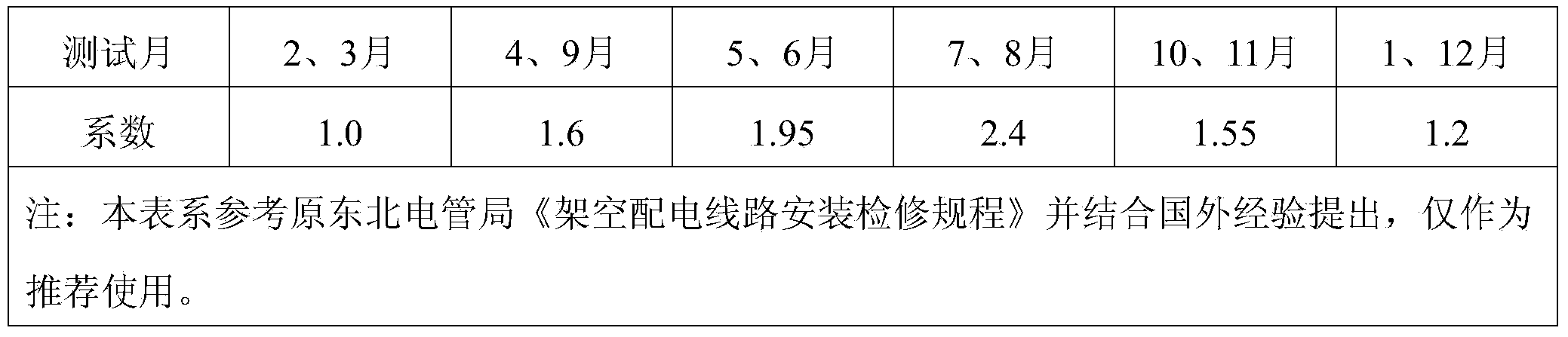

Portable seasonal factor tester

InactiveCN104375009AImprove scienceImprove accuracyEarth resistance measurementsDot matrixEngineering

The invention relates to the technical field of electric power testing instruments, in particular to a portable seasonal factor tester. A probe is connected with a tester body through a coaxial transmission line; a pulse signal generator is arranged in the tester body, connected with the probe through the coaxial transmission line and further connected with a high-frequency oscillograph through a synchronizing signal generator; the other end of the high-frequency oscillograph is connected with the probe through the coaxial transmission line. The portable seasonal factor tester can visually and accurately measure the seasonal factor; according to the physical phenomenon that the running speed of electromagnetic waves will change when the electromagnetic waves are spread in media of different dielectric constants, the dielectric constant of a gas-solid-liquid mixture in soil is obtained by measurement. The portable seasonal factor tester has the advantages of convenient carrying, a touch-type button, large-screen dot-matrix type liquid crystal display, all Chinese menu operation, easy, rapid and convenient operation and high practicability, and the scientificity and accuracy of ground resistance testing work can be improved remarkably.

Owner:STATE GRID CORP OF CHINA +1

Low-voltage wire section measuring instrument

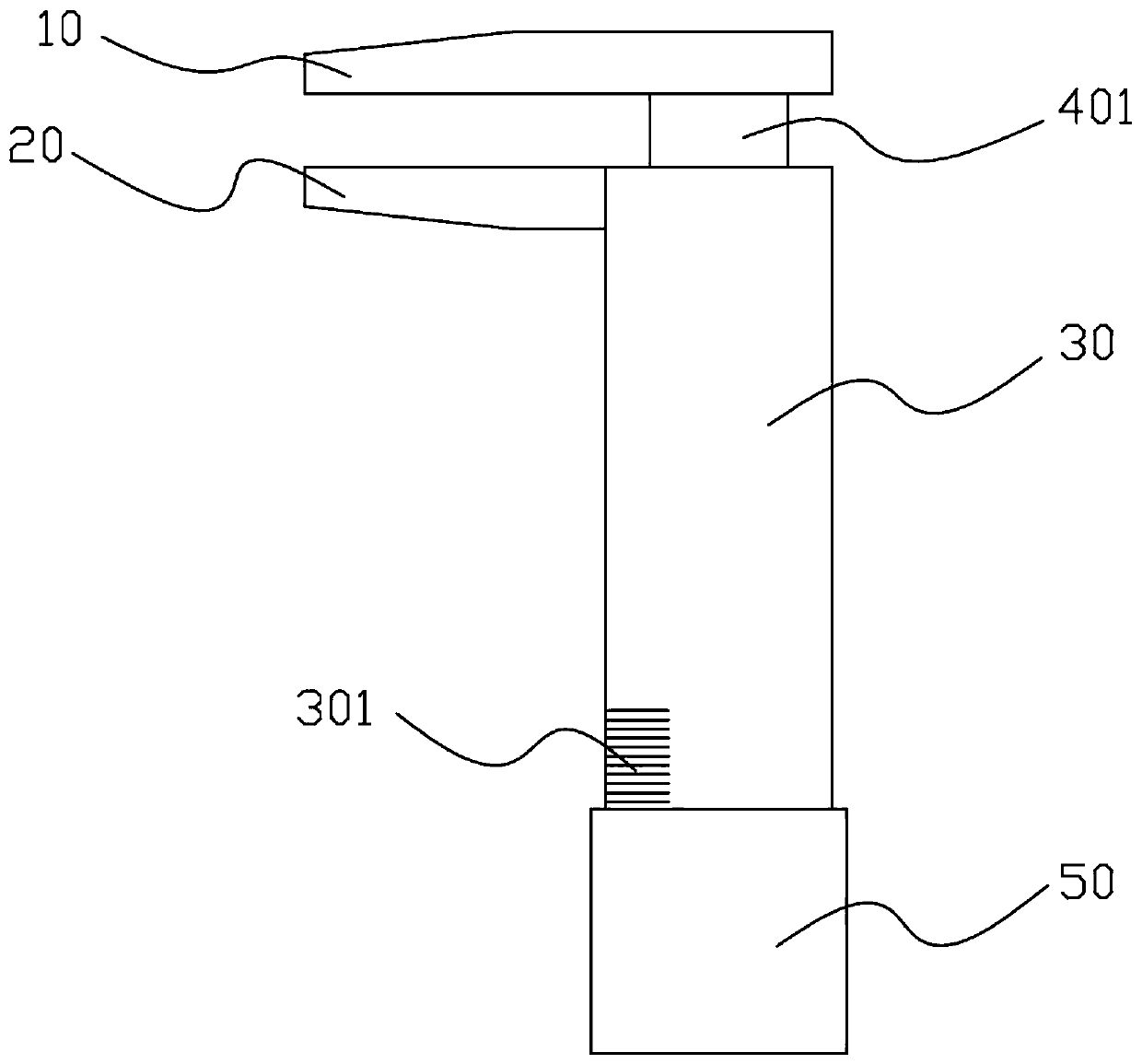

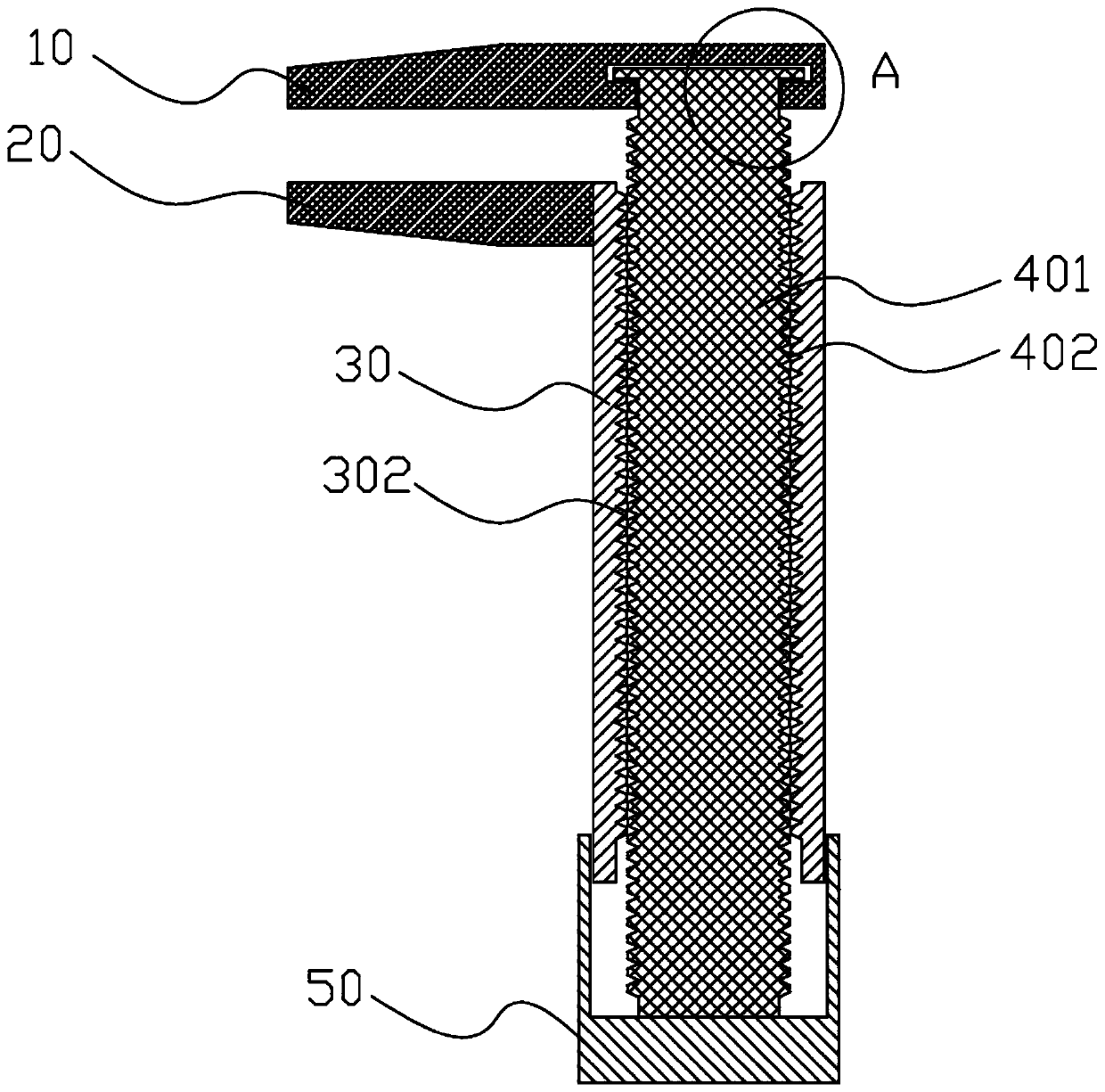

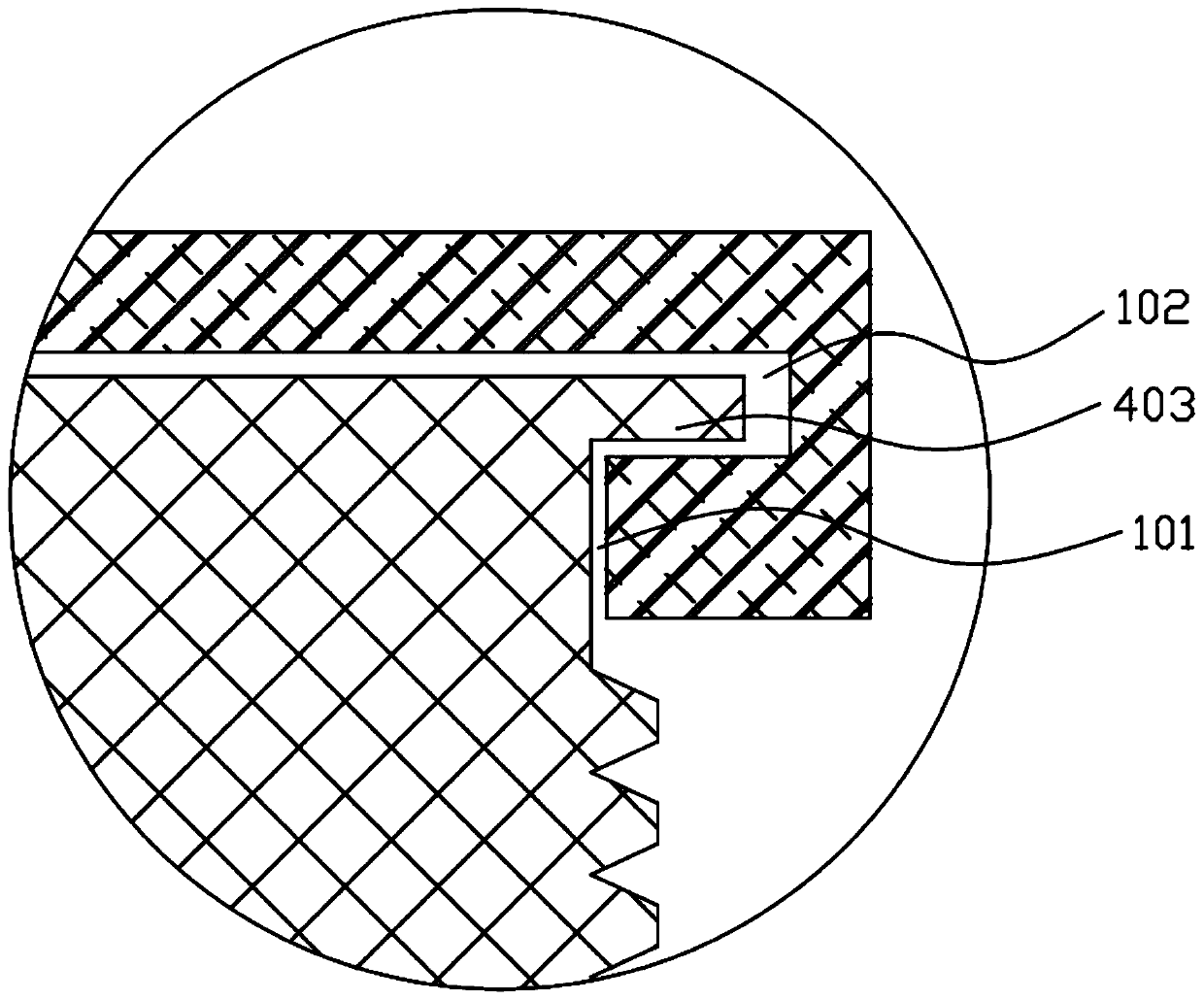

InactiveCN111595224AEasy and intuitive measurementWon't move easilyMechanical diameter measurementsMeasurement deviceMeasuring instrument

The invention relates to the technical field of measuring devices, and in particular, relates to a low-voltage wire section measuring instrument which comprises an upper clamping piece, a lower clamping piece, a main body and a driving rod, the driving rod is connected with the upper clamping piece, the lower clamping piece is connected with the main body, scale marks are arranged on the main body, and the driving rod is movably connected with the main body through a thread pair. A wire can be measured accurately and efficiently.

Owner:GUANGDONG POWER GRID CO LTD +1

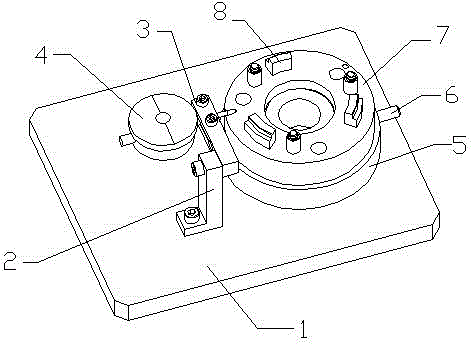

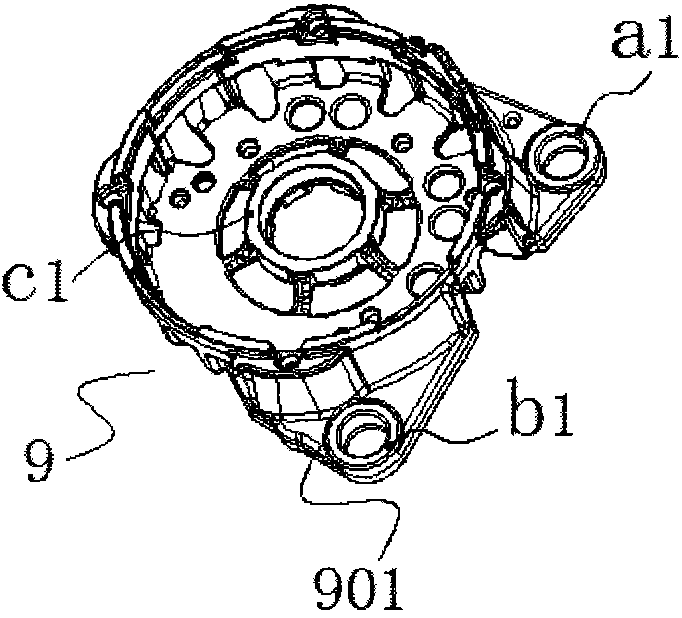

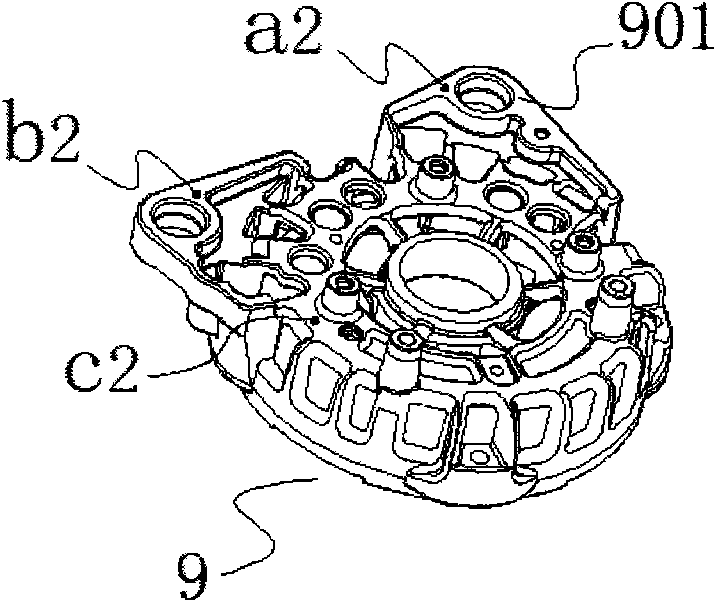

Small end cover surface roundness dial plate type measuring instrument

InactiveCN104390566AReliable detectionImprove efficiencyMechanical counters/curvatures measurementsMeasuring instrumentSpare part

The invention belongs to the fixture and gauge field and discloses a small end cover surface roundness dial plate type measuring instrument. The small end cover surface roundness dial plate type measuring instrument comprises a base; the base is horizontally provided with an elastic clamping plate through a vertical main upright rod; the elastic clamping plate is provided with a dial indicator; a supporting seat is arranged beside the main upright rod; the upper surface of the supporting seat is provided with a plurality of supporting blocks for limiting an end cover to be measured; and the pointer of the dial indicator points to the supporting seat. The small end cover surface roundness dial plate type measuring instrument of the invention has the advantages of effective and reliable detection, being intuitive, high efficiency, low error rate, no technical requirements for operation personnel, being conducive to manual operation, little possibility of causing fatigue, high work high precision, low manufacturing cost, easiness in manufacture and processing, easiness in spare part replacement and high interchangeability.

Owner:蒋剑锋

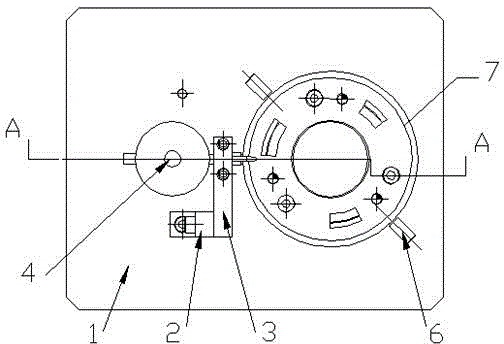

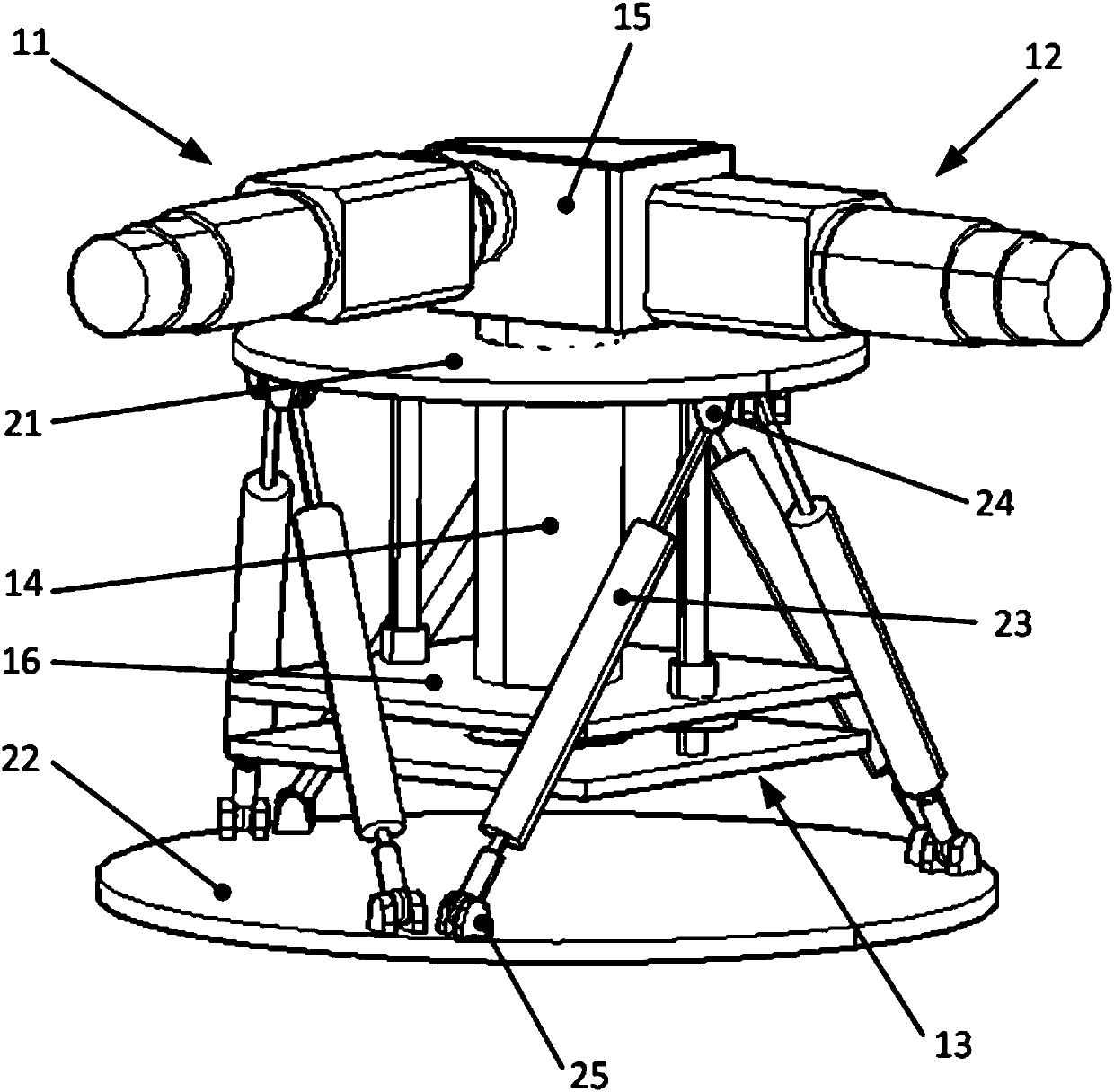

A wave compensation measurement device, measurement method and ocean platform using the same

ActiveCN106882344BReduce the difficulty of heave compensation measurementReduce cost of measurementShip vibration reductionMovement controllersMarine terraceMeasurement device

The invention discloses a wave compensation measuring device, a measuring method and an applicationthereof in an ocean platform. The wave compensation measuring device comprises acompensation drive unit and a platform displacement measurement unit, the compensation drive unit comprises a rolling compensation drive device, a pitch compensation drive device, a heave compensation drive device and a drive connection rod; the connection between an upper measurement plate and a lower measurement plate is connected with six linear displacement sensors. The platform displacement measurement unit is arranged to simulatethe six degrees of freedom platform, whereinthe six linear displacement sensors correspond to the six servo cylinders of the six degrees of freedom platform; a compensation drive unit is arranged so as to conductwave compensations on theplatform displacement measurement unit, thus the wave compensation volume of theservo cylinders of the six degrees of freedom platform six is measured, the complex parallel connection machine program algorithm is converted into a mechanical news transmission mechanism, and the wave compensation measurement difficulty is reduced.

Owner:KEEN OFFSHORE ENG CO LTD

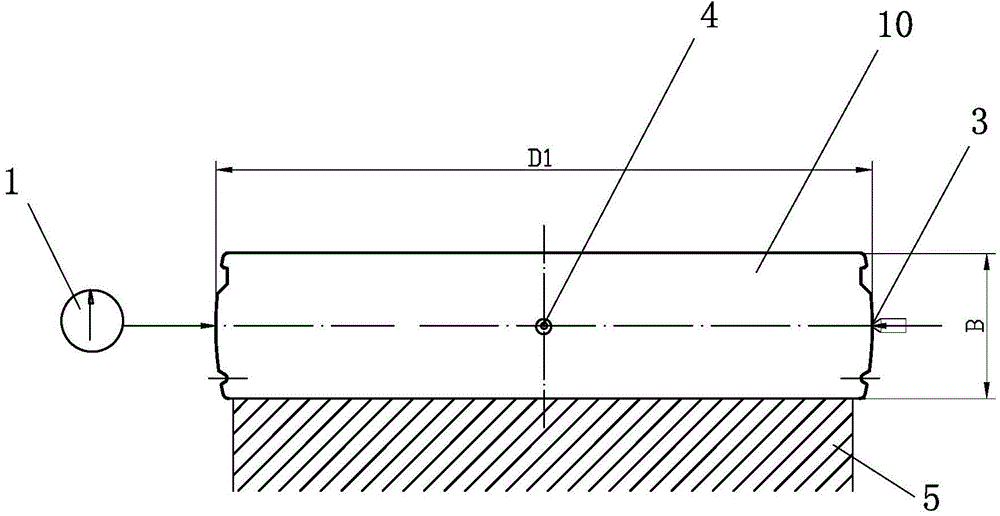

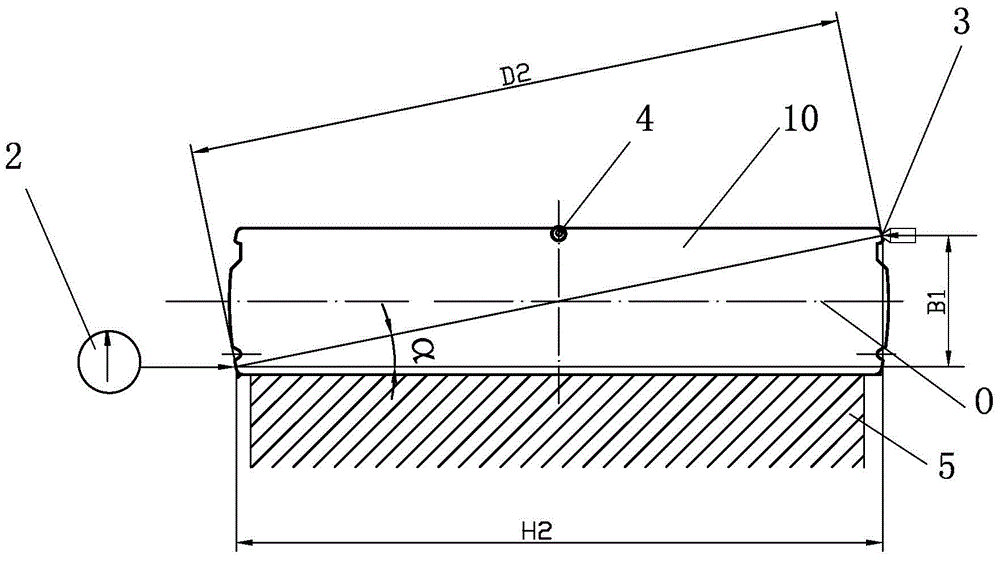

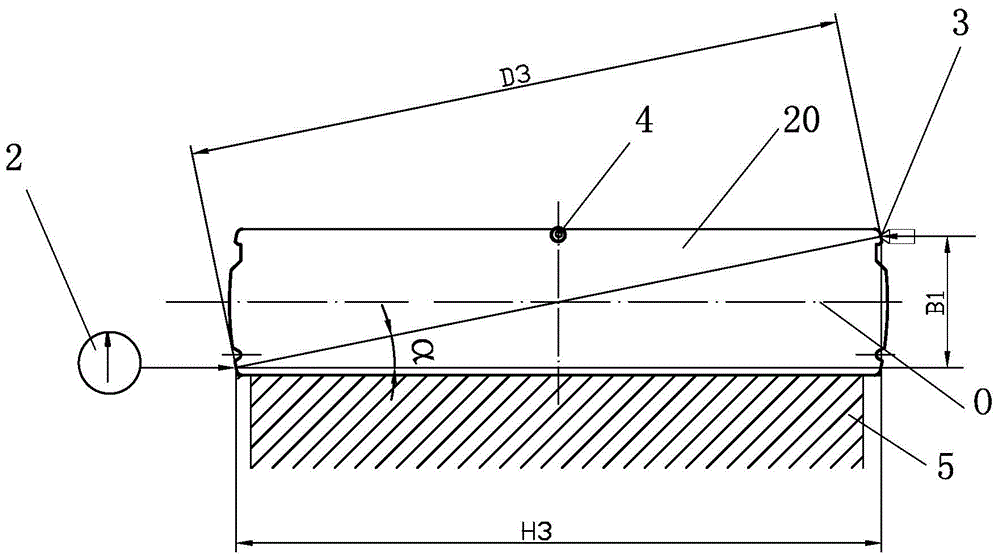

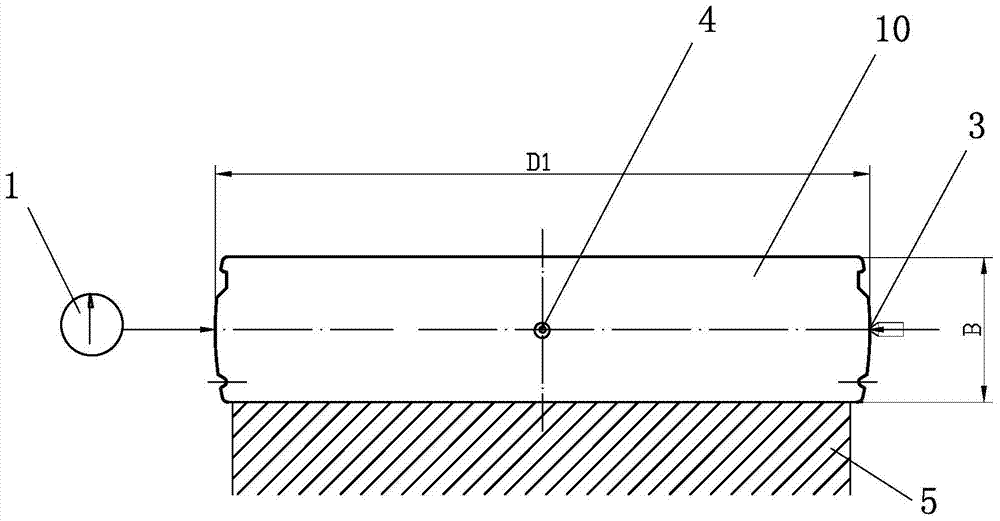

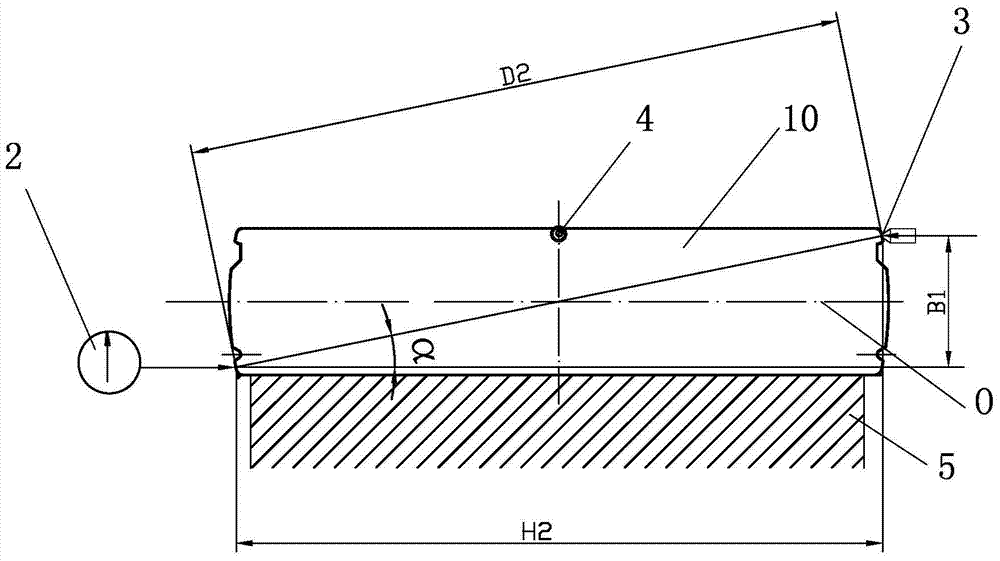

Method for measuring spherical outside surface of bearing

InactiveCN104019727AEasy to measureSimple stepsMechanical counters/curvatures measurementsSpherical shapedEngineering

The invention provides a method for measuring a spherical outside surface of a bearing. The method comprises the following steps: (1) selecting a standard element, measuring and labeling a sphere diameter D1 at the center point in the width direction of the standard element and a sphere diameter D2 at opposite angles; (2) calibrating a first instrument by using the spherical diameter D1 at the center point of the standard element; (3) calibrating a second instrument by using the sphere diameter D2 at opposite angles of the standard element, wherein the support force of a measurement head and a support point of the second instrument points to the axis of the standard element; (4) measuring the sphere diameter in the middle of a workpiece by using the first instrument under the condition that the calibration state is same as the calibration states in the steps (2) and (3), so as to obtain a deviation value D1', and measuring the sphere diameter at the opposite angles by using the second instrument, so as to obtain a deviation value D2'; and (5) obtaining a difference value by using D1'-D2' and comparing the difference value with the set spherical deviation. The method is convenient and accurate to measure, and is not dependent on the judgment experience of detecting personnel, and the requirements of the product quality are ensured.

Owner:奥新(厦门)轴承有限公司

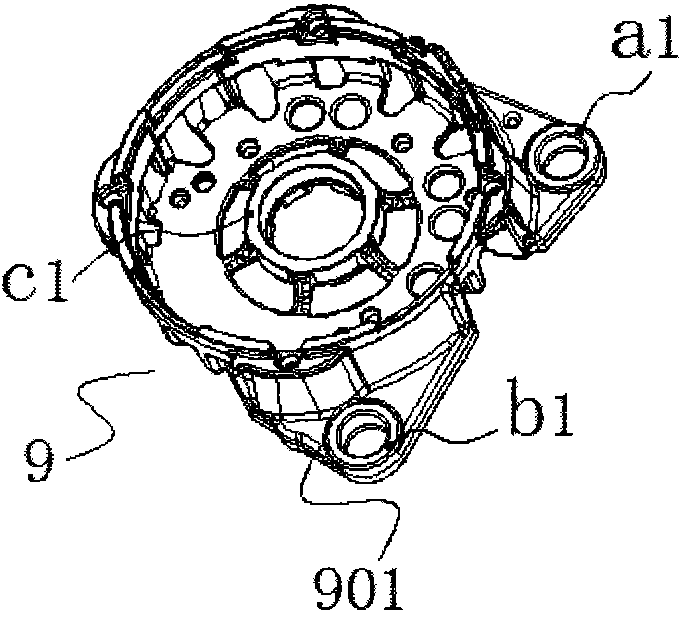

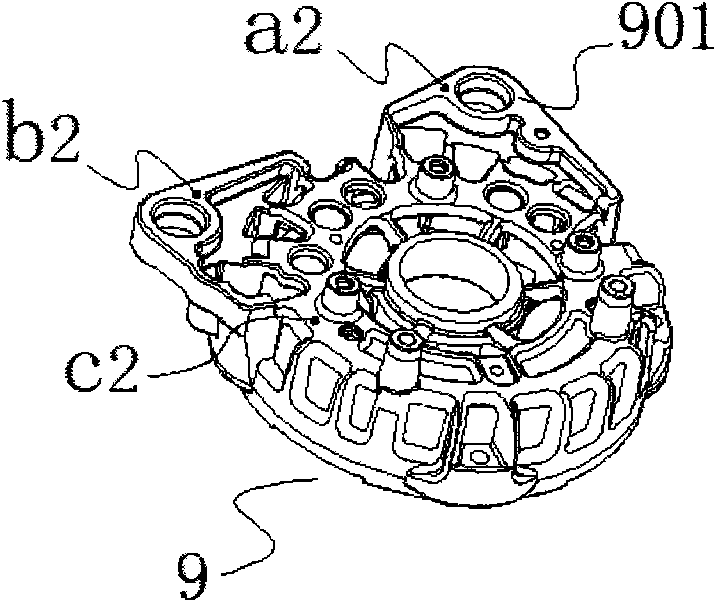

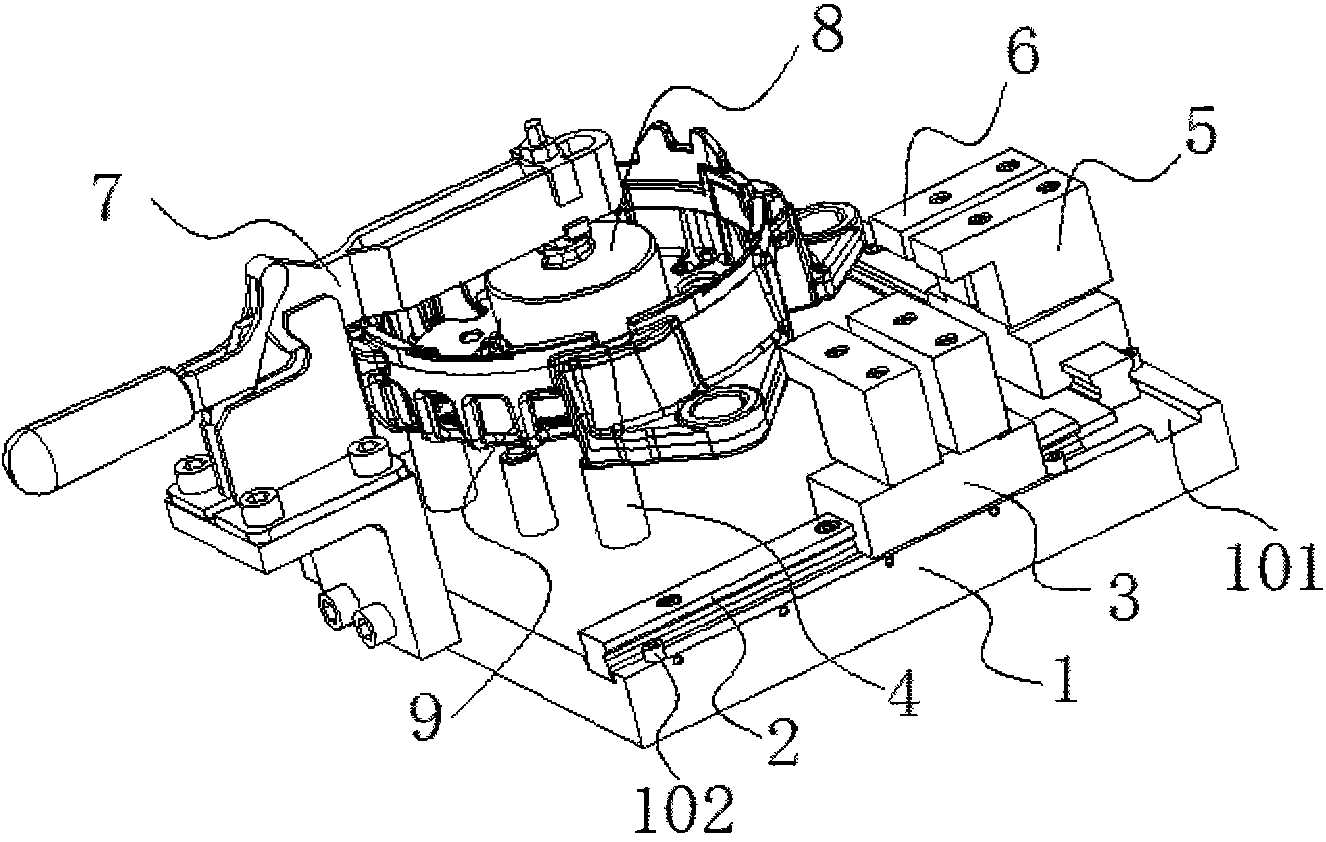

Small end cap end face height guide rail detection device

ActiveCN103913104AImprove working precisionReduce manufacturing costMechanical measuring arrangementsSpare partEngineering

The invention belongs to the field of clamp detection devices, and discloses a small end cap end face height guide rail detection device. The device comprises a bottom plate, wherein the left of the bottom plate is provided with a clamping mechanism, the lower end of the clamping mechanism is provided with a pressing plate, the side edge of the bottom plate is provided with a guide rail where a sliding block is arranged, and the sliding block is provided with a non-go gauge and a go gauge. According to the small end cap end face height guide rail detection device, in terms of the principle of the non-go gauge and the go gauge, the detection process is visual, detection efficiency is high, the error rate is low, the device has no requirements for techniques of operators, manual operation is facilitated, fatigue is not prone to occurrence, work precision of the detection device is high, manufacturing cost is low, the device is easy to manufacture and machine, spare parts are easy to replace, and interchangeability is high.

Owner:CHANGSHA BODA MACHINERY PARTS CO LTD

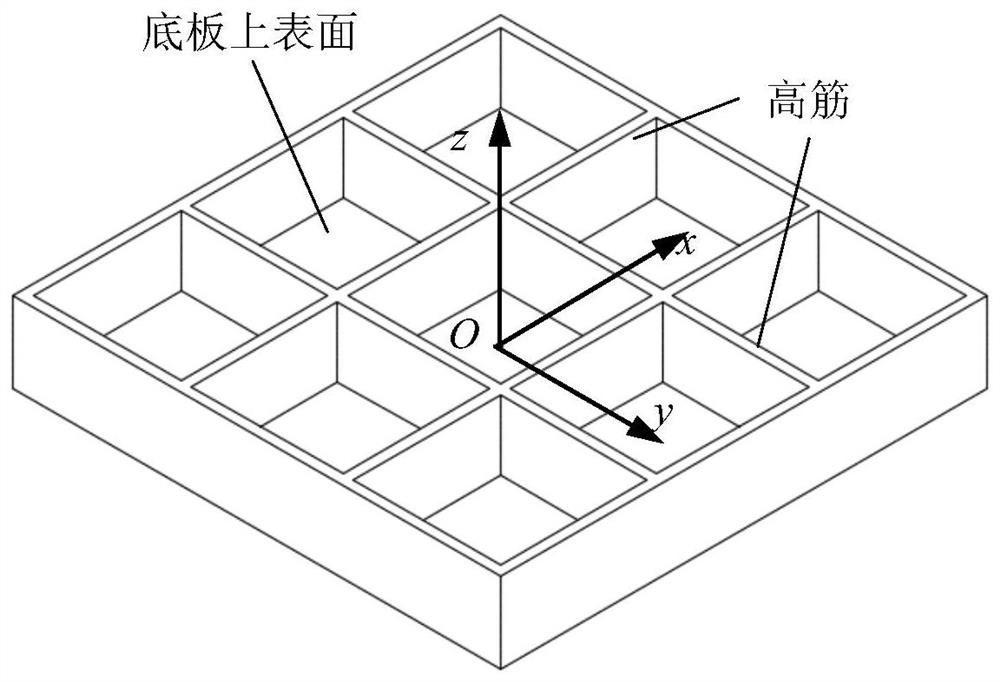

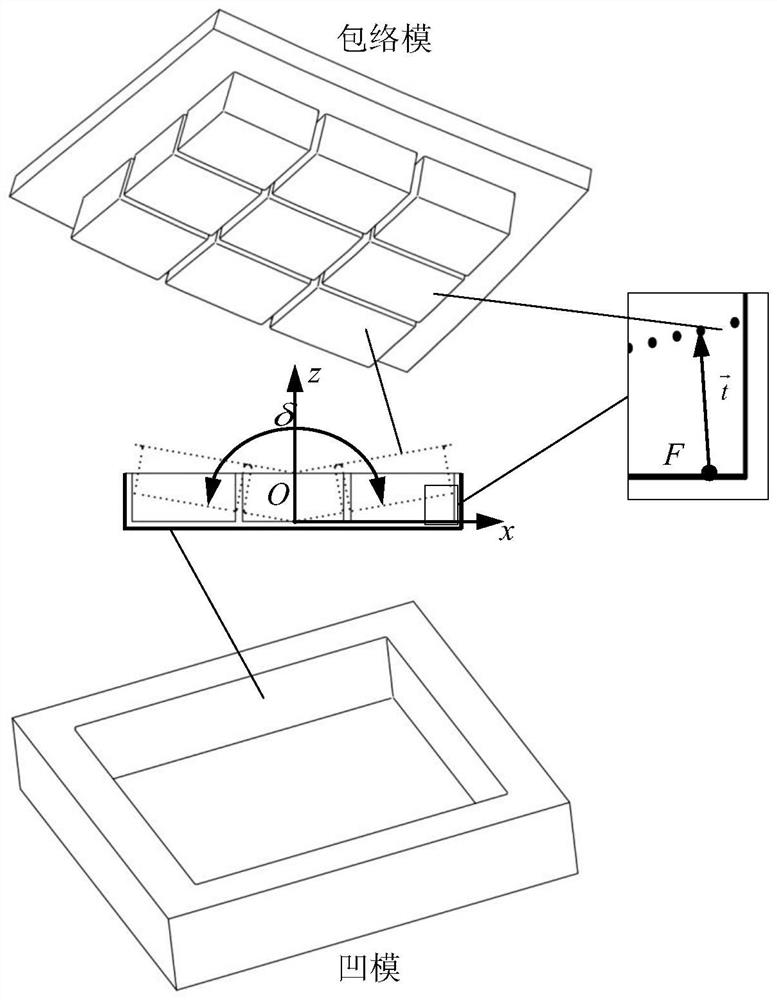

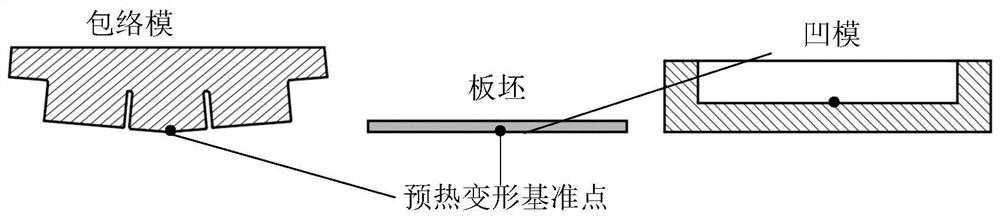

Method for predicting space envelope forming precision of high-rib thin-wall component

ActiveCN113076598ARefined cooling shrinkage forgingsAccuracy Prediction Model Enables Accurate Cooling of Shrinkage ForgingsGeometric CADDesign optimisation/simulationAlgorithmMechanical engineering

The invention relates to a method for predicting the space envelope forming precision of a high-rib thin-wall component. The method comprises the following steps: S1, a finite element prediction model for the space envelope forming precision of the high-rib thin-wall component is established; S2, the space envelope forming shape deviation of the high-rib thin-wall component is determined; s3, the space envelope forming size deviation of the high-rib thin-wall component is determined; and S4, the space envelope forming geometric deviation of the high-rib thin-wall component is determined. According to the method for predicting the space envelope forming precision of the high-rib thin-wall component, the space envelope forming precision of the high-rib thin-wall component under thermal-mechanical coupling and multi-deformation zone coordination can be accurately predicted, and a foundation is laid for precise forming of the high-rib thin-wall component.

Owner:WUHAN UNIV OF TECH

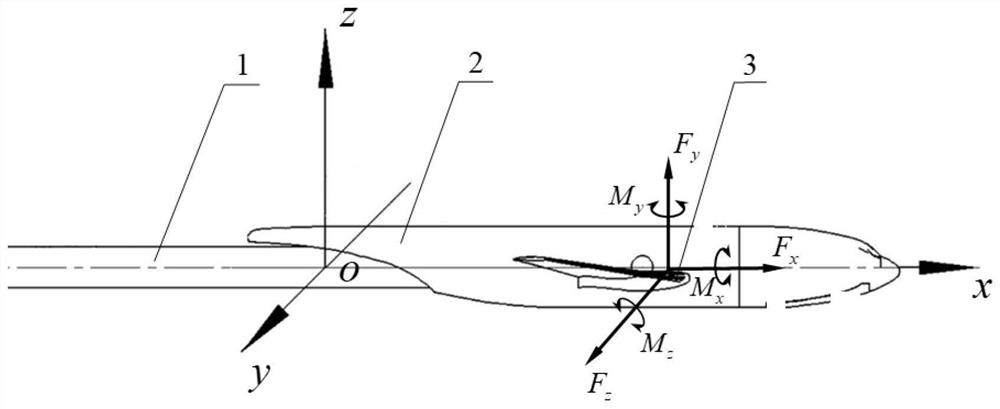

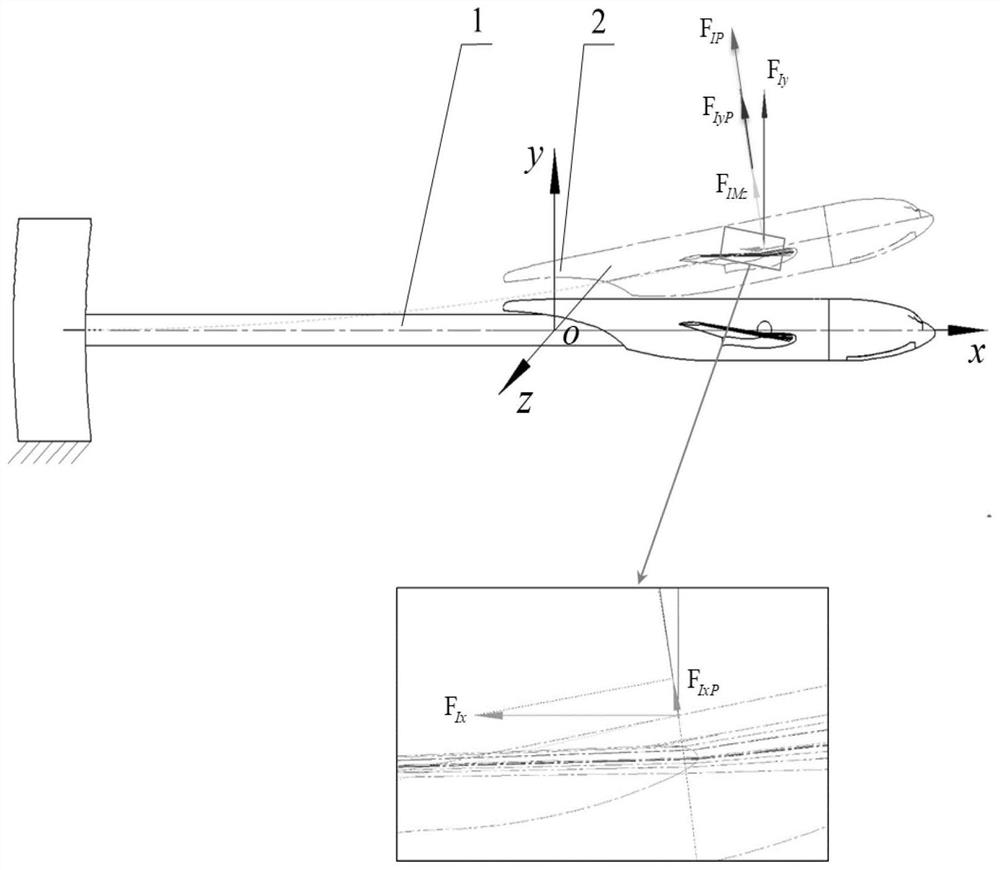

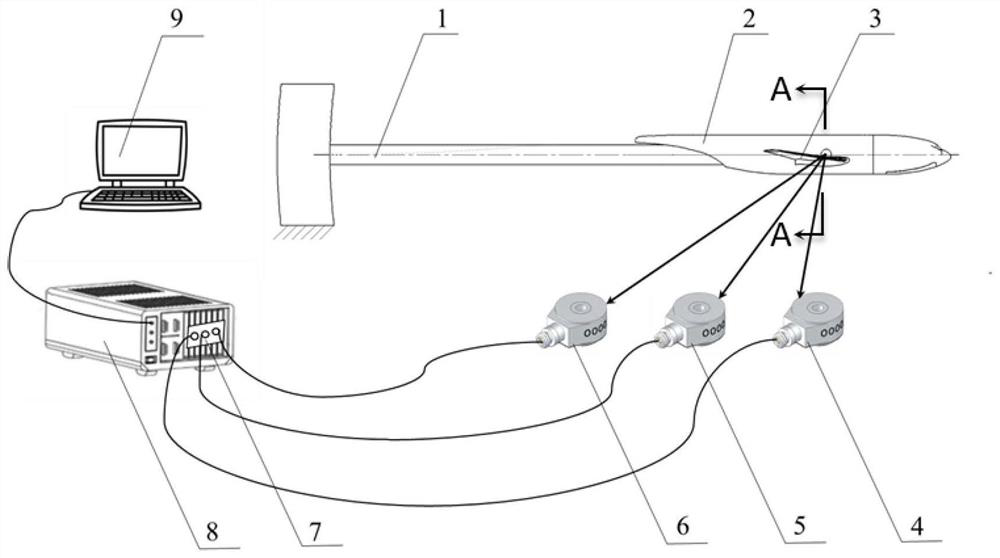

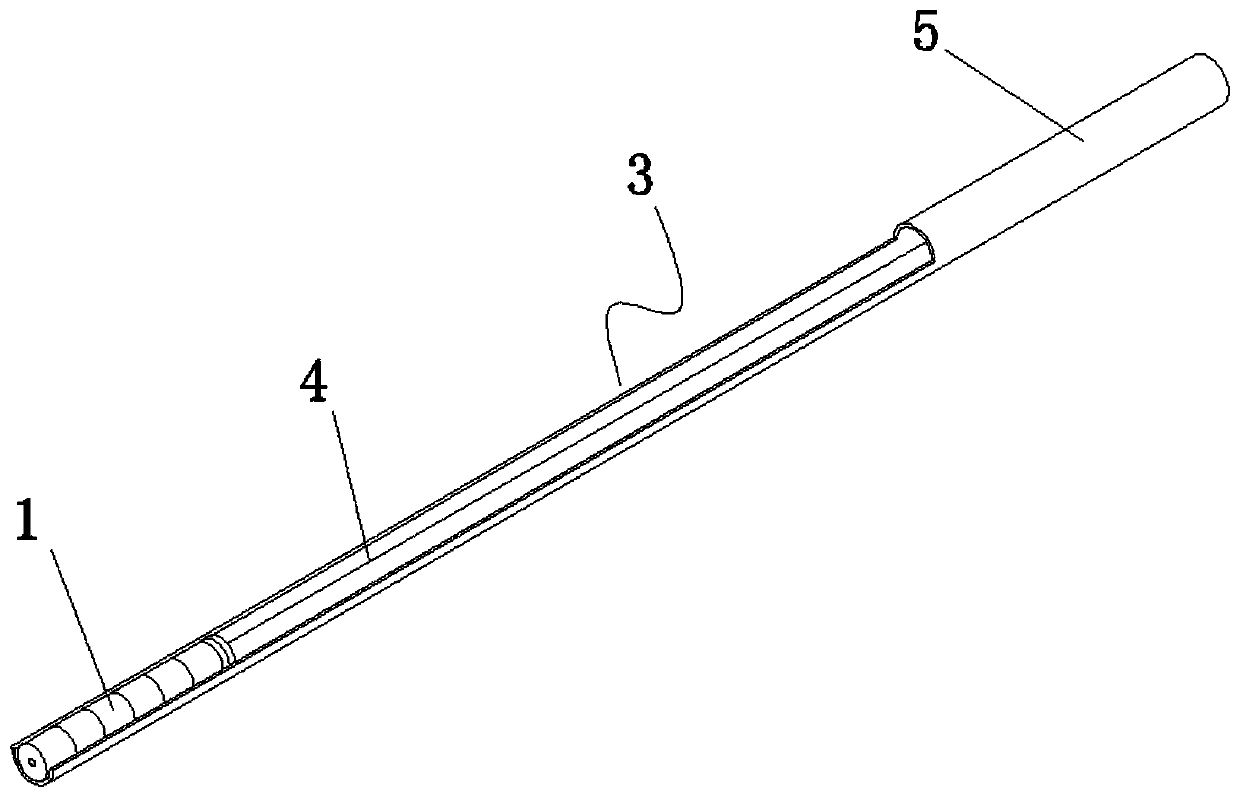

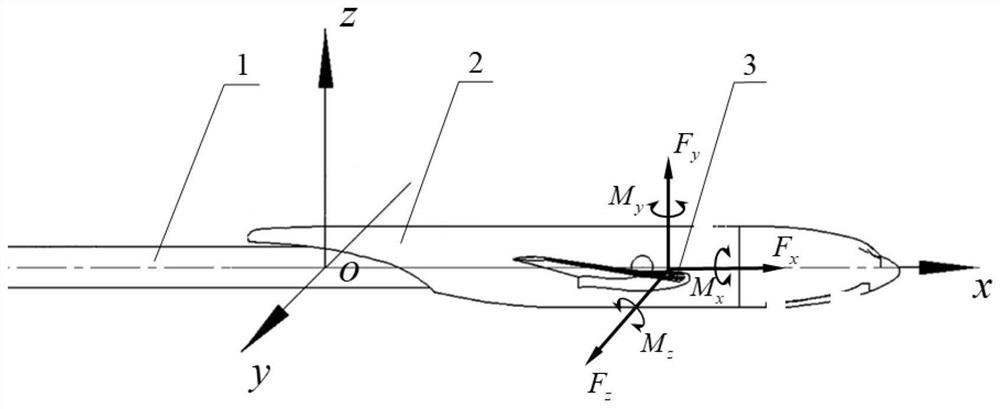

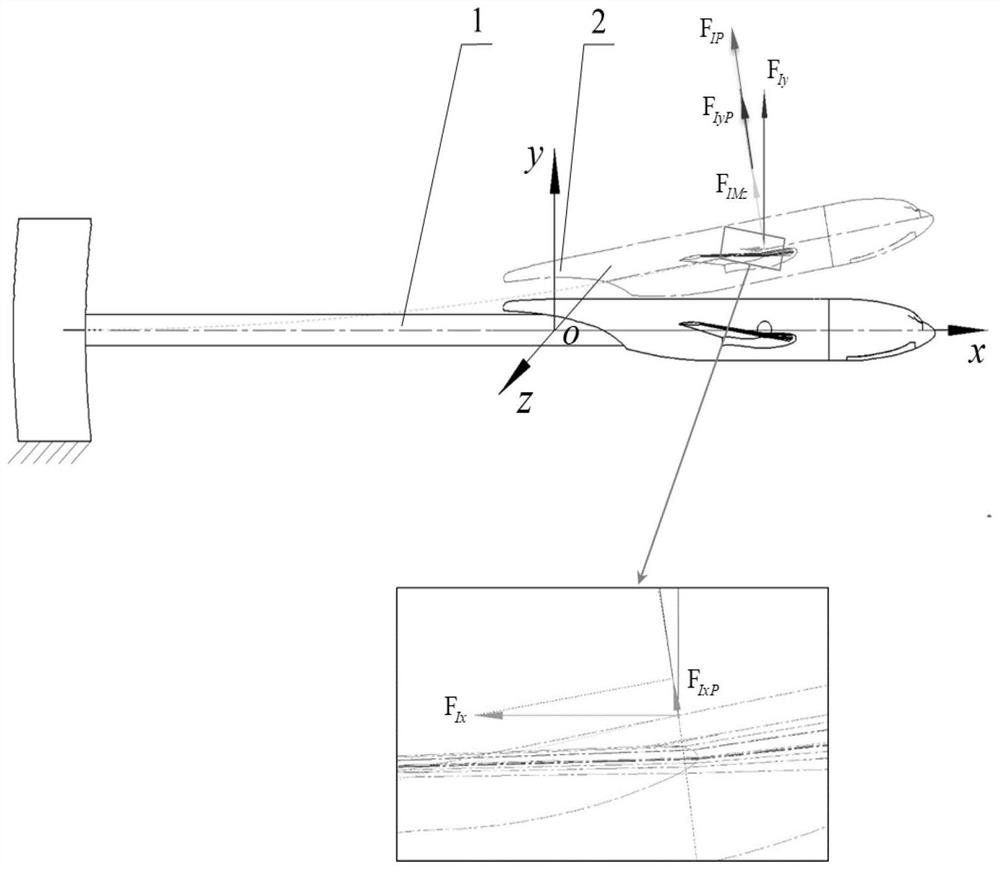

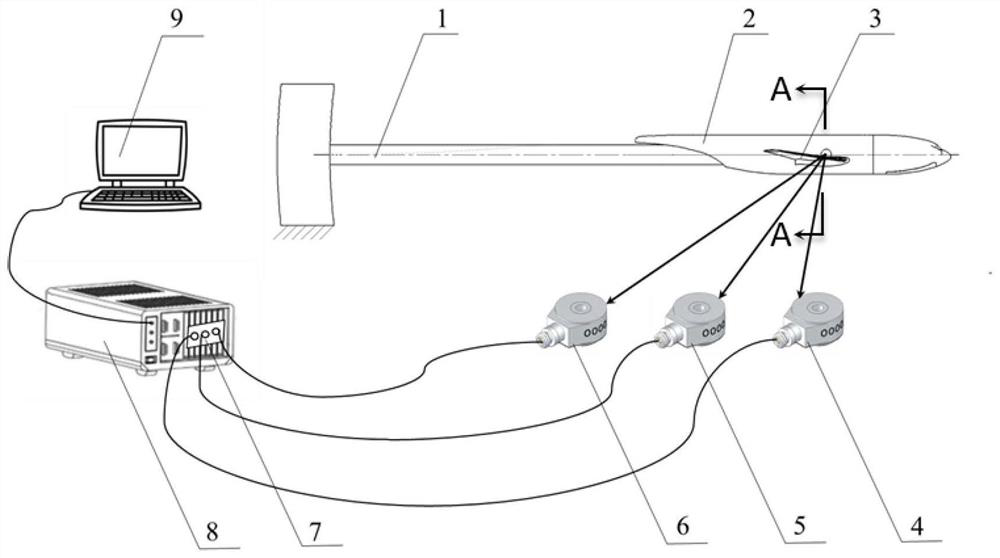

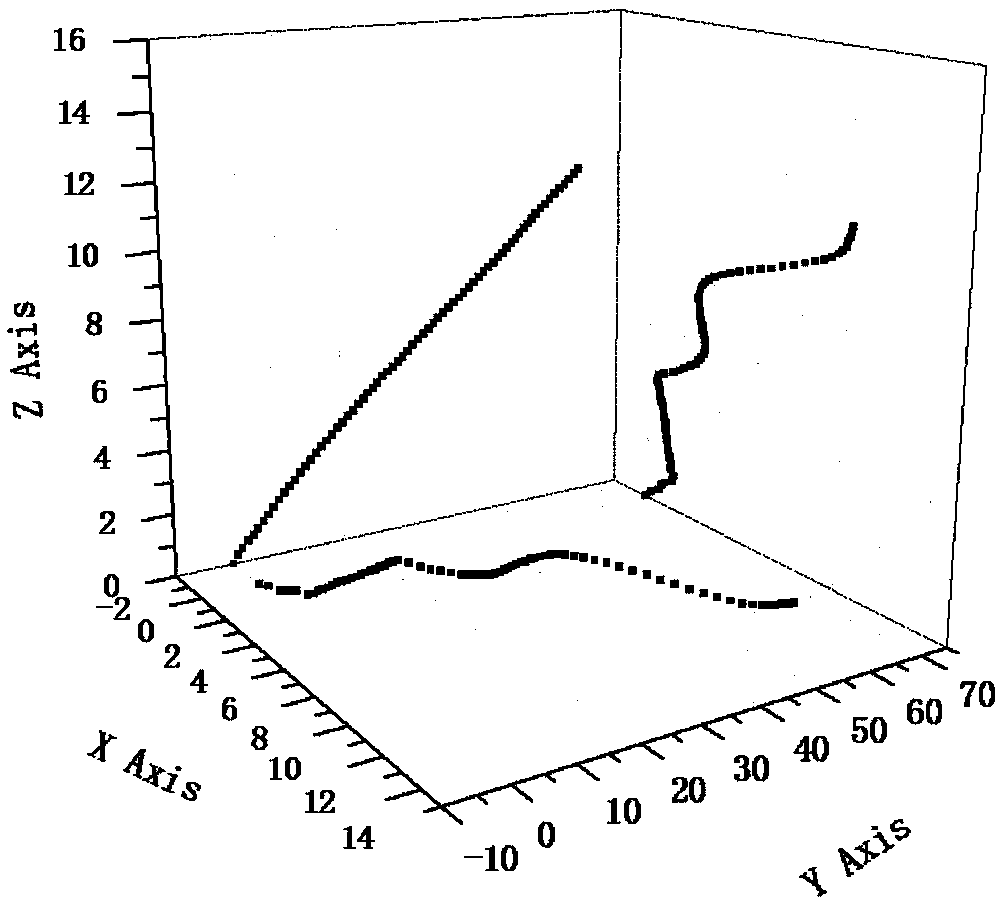

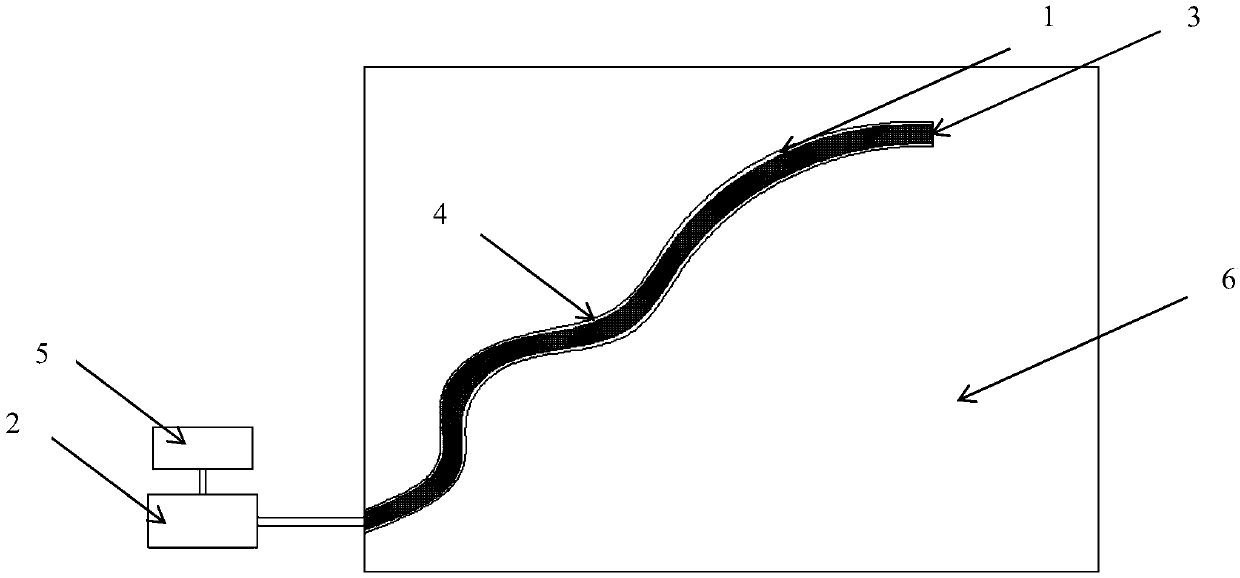

Dimension reduction monitoring method for random multi-dimensional vibration of aircraft model

ActiveCN112033636AIntuitive and accurate multi-dimensional vibrationIntuitive and accurate measurementAerodynamic testingVertical planeFlight vehicle

The invention discloses a dimension reduction monitoring method for random multi-dimensional vibration of an aircraft model, belongs to the field of aircraft wind tunnel model vibration monitoring, and relates to a dimension reduction monitoring method for multi-dimensional vibration applied to a strut tail boom type aircraft model wind tunnel test. According to the dimension reduction monitoringmethod, multi-dimensional vibration of the aircraft model is decoupled in a pitching plane and a yawing plane, dimensionality reduction is expressed as inertia observation forces on two planes perpendicular to each other through utilizing an acceleration sensor arranged on a multi-dimensional vibration monitoring system, vibration characteristics of selected random vibration are observed in the pitching plane and the yawing plane in a dimensionality reduction mode, and random multi-dimensional vibration monitoring of the aircraft model is realized. According to the dimension reduction monitoring method provided by the invention, the measurement accuracy degree is improved, and the observation method is high in feasibility and strong in adaptability, and can be applied to a rapidly developed aircraft wind tunnel simulation test.

Owner:DALIAN UNIV OF TECH

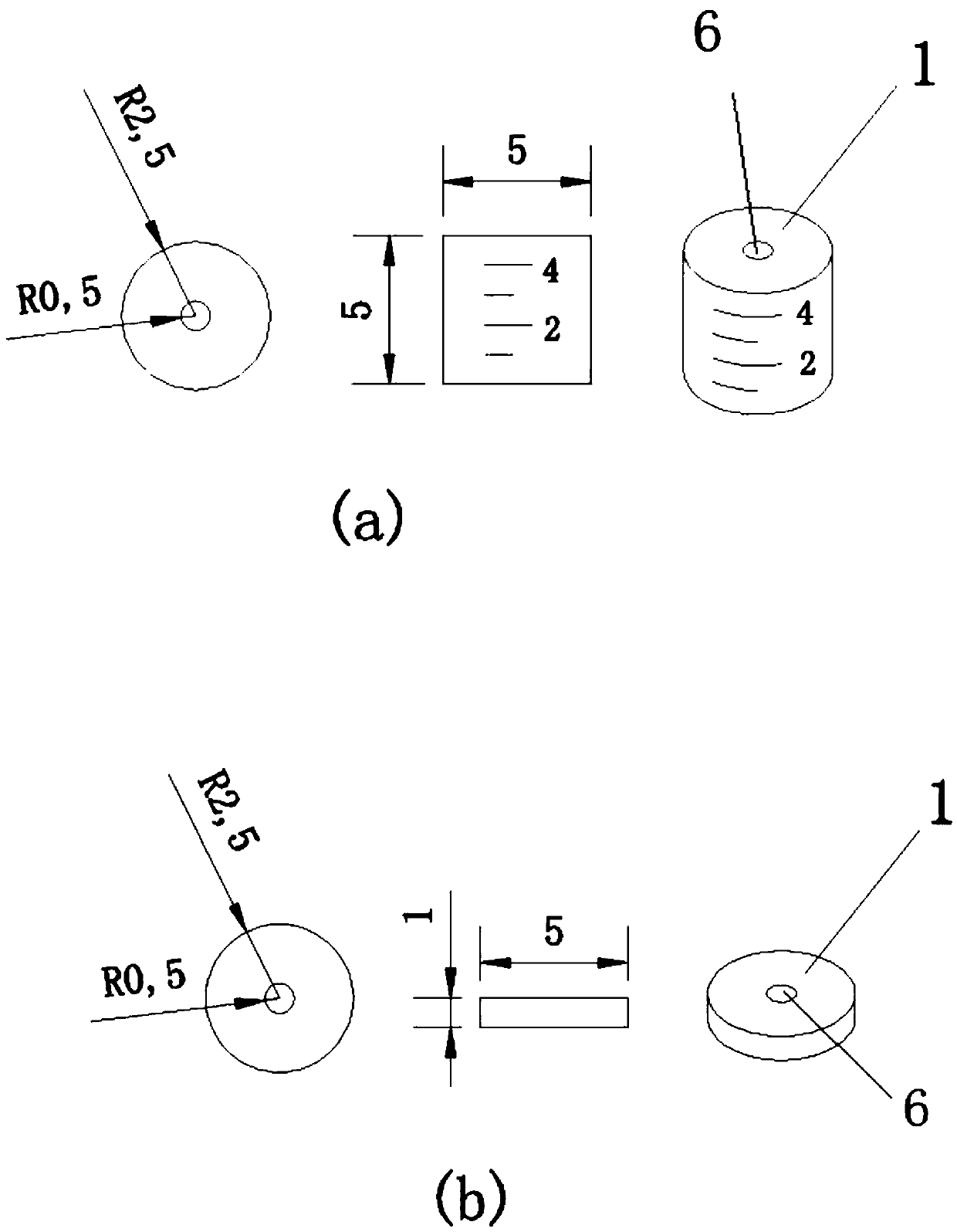

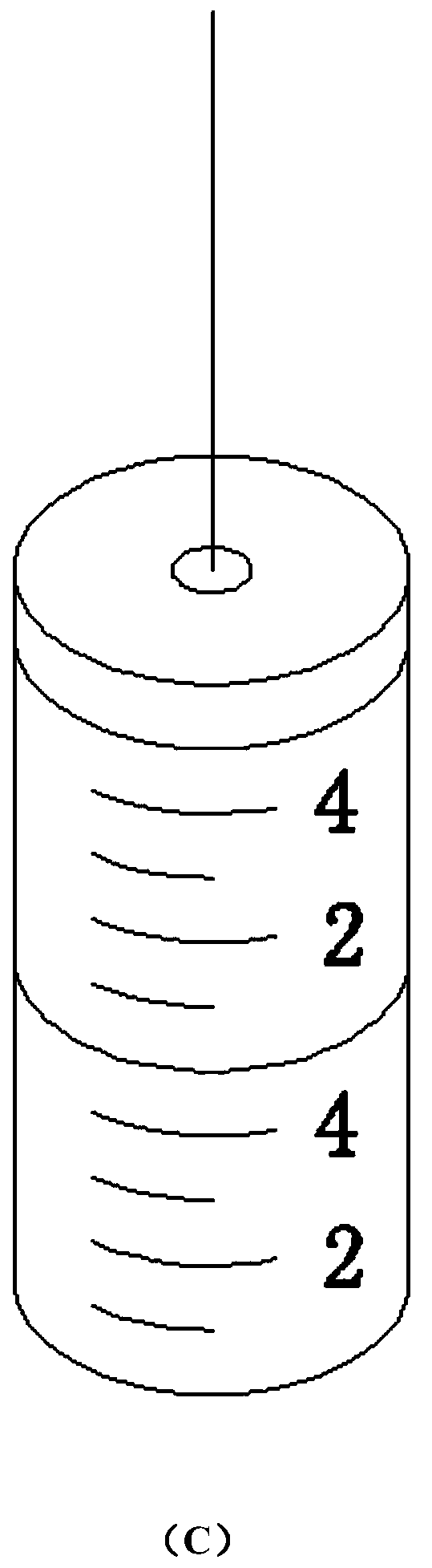

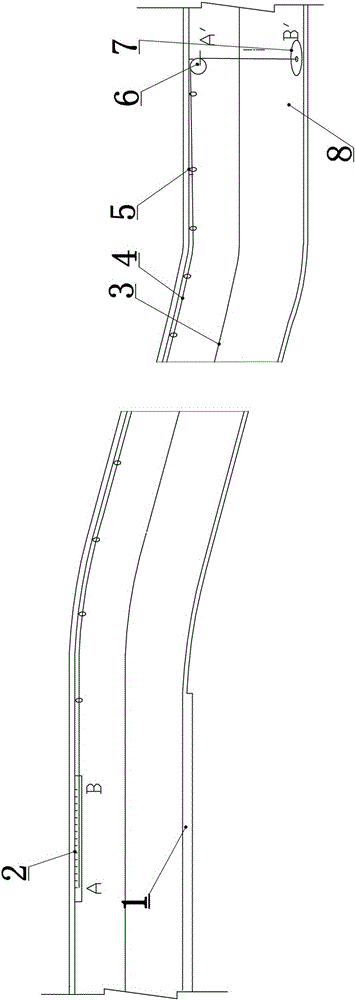

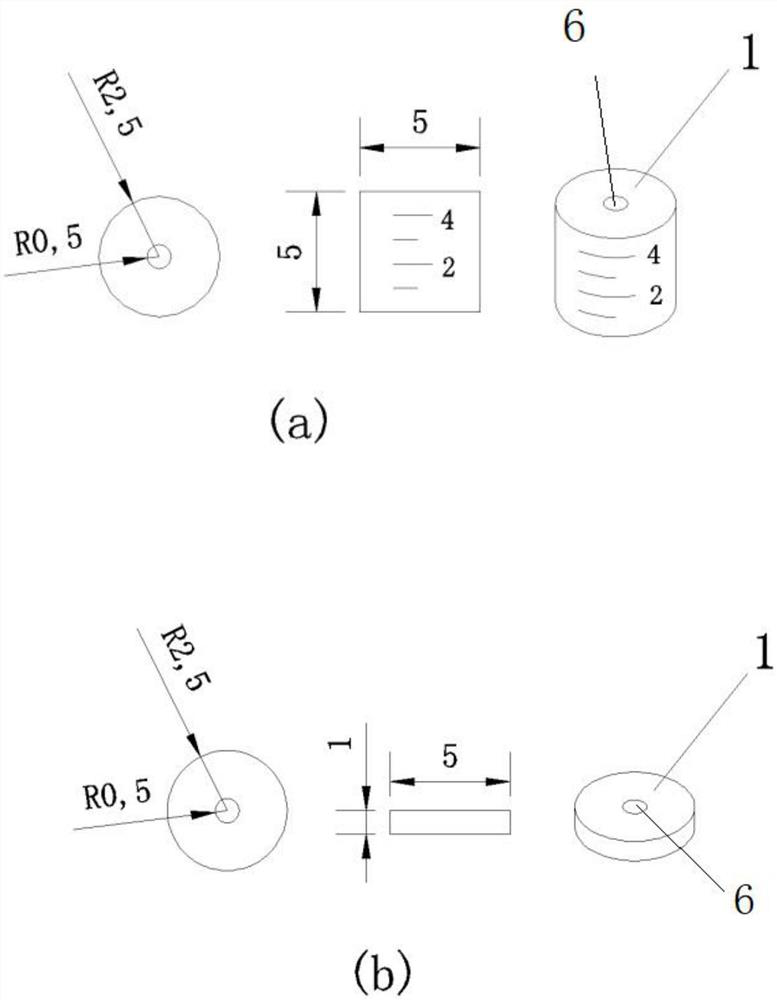

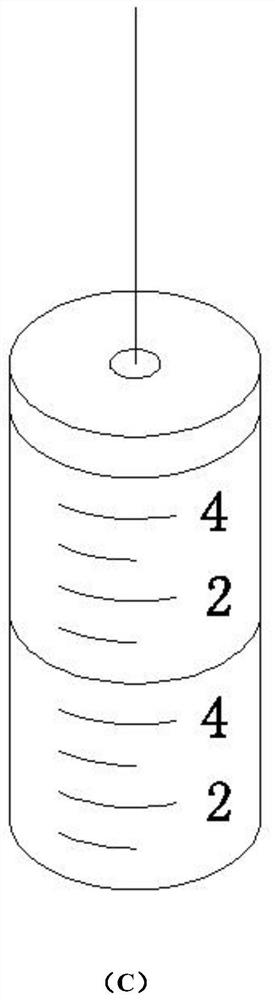

Method for detecting height of slurry surface inside grouting sleeve by using standard thickness weight

ActiveCN110487349ASimple methodLow priceMachines/enginesLevel indicatorsSlurryMechanical engineering

The invention provides a method for detecting the height of the slurry surface inside a grouting sleeve by using a standard thickness weight, wherein the method uses a device for detection. The devicecomprises standard weights (1), a connecting line (2), and a weight tube (3). To be specific, the method comprises: connecting the connecting line (2) to one standard weight (1)fixedly and to other weights in series, arranging the connection part at the front end of the weight tube (3), and holding a connecting end or connecting the connecting end fixedly by a fixed support device and leading theweights out of a to-be-detected grouting sleeve though a slurry outlet hole till exceeding the slurry outlet hole of the sleeve by the weights, and indicating the unfilling height of the grouting sleeve according to the led weight thickness sum and a scale displayed by a last weight. The method is accurate and simple and is easy to operate.

Owner:湖南新懋旭科技有限公司

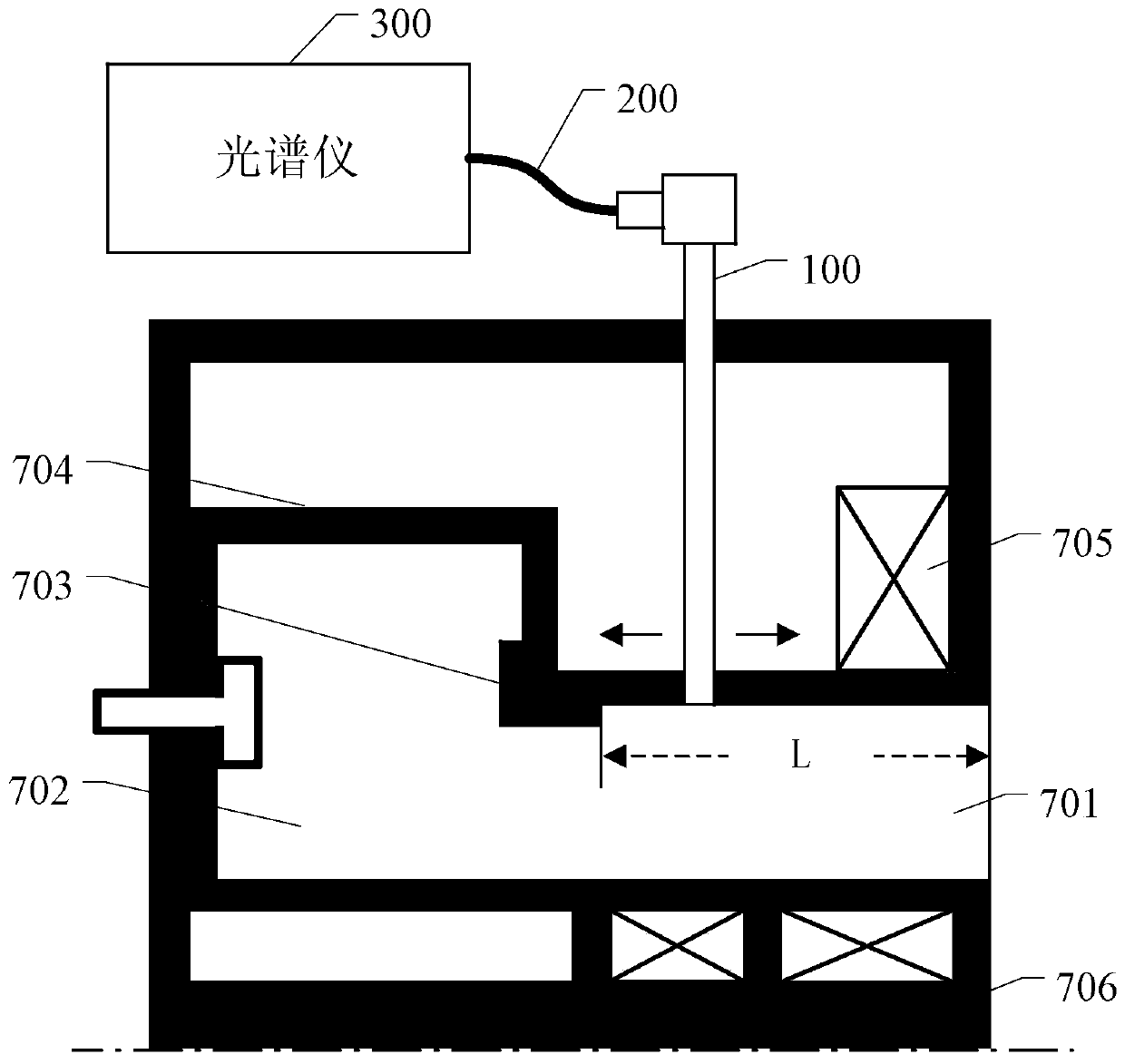

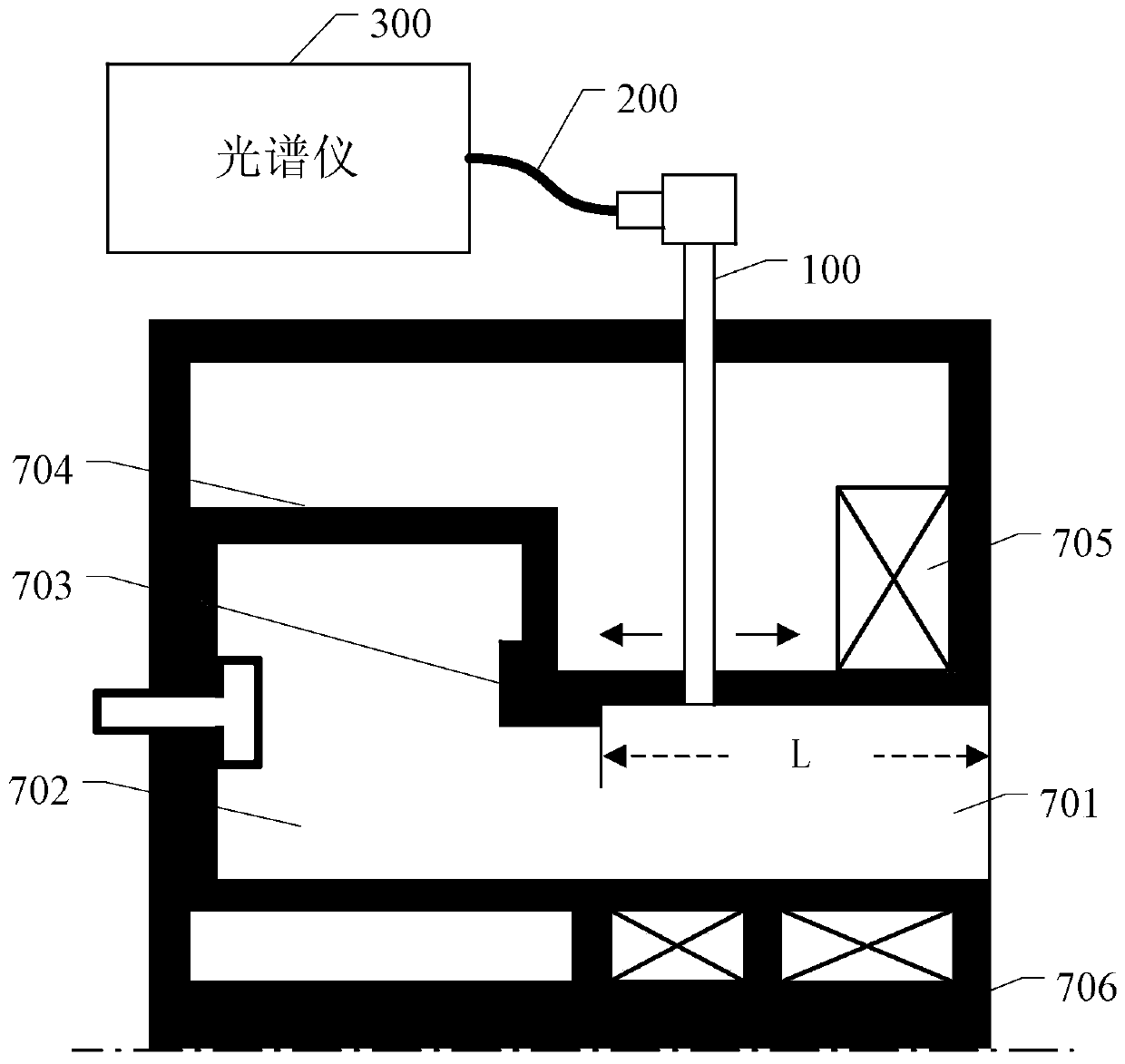

An online monitoring device and method for electronic and atomic parameters in the discharge channel of a kryptonian Hall thruster

ActiveCN107228829BAvoid interferenceDoes not affect the ionization processColor/spectral properties measurementsKryptonLight guide

The invention relates to online monitoring technology for the parameters of electrons and atoms in the discharge channels of krypton Hall thrusters and provides an online monitoring device and method for the parameters of electrons and atoms in the discharge channel of a krypton Hall thruster to meet the demand for monitoring of ionization degrees in the discharge channel of the krypton Hall thruster. The online monitoring device comprises a light guiding pipe, an optical fiber and a spectrometer, wherein the sidewall of the discharge channel of the Hall thruster is provided with an axial testing slit; the light guiding pipe is inserted into the axial testing slit and used for guiding light in the discharge channel into the optical fiber; and the optical fiber is connected with the spectrometer. The spectrometer measures the intensities of krypton atom spectral lines with wavelengths of 805.95 nm, 785.48 nm, 760.15 nm and 758.74 nm, respectively; and the temperature of electrons and the density of krypton atoms are calculated according to the intensities of the krypton atom spectral lines. The online monitoring device and method provided by the invention are applicable to monitoring of the parameters of electrons and atoms in discharge channels.

Owner:HARBIN INST OF TECH

Tank Siltation Measuring Device

ActiveCN103471680BImprove securityReduce harmMachines/enginesLevel indicatorsEngineeringMeasuring ruler

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

A method for measuring the outer spherical surface of a bearing

InactiveCN104019727BEasy to measureSimple stepsMechanical counters/curvatures measurementsSpherical bearingMeasuring instrument

The invention provides a method for measuring the outer spherical surface of a bearing, comprising the following steps: (1), selecting a standard part, measuring and marking the ball diameter D1 at the midpoint in the width direction of the standard part and the ball diameter D2 at the opposite corner; (2), Use the ball diameter D1 at the midpoint of the standard part to calibrate the first meter; (3), use the ball diameter D2 at the opposite corner of the standard part to calibrate the second meter, and the supporting force of the second meter measuring head and the support point points to the axis of the standard part; ( 4) Under the same conditions as the proofreading state of step (2) and step (3), use the first instrument to measure the ball diameter in the middle of the workpiece to obtain the deviation value D1', and then use the second instrument to measure the diagonal position of the workpiece Ball diameter, get the deviation value D2'; (5), use D1'‑D2', get the difference and compare it with the set spherical deviation. The invention is convenient and accurate in measurement, does not rely on the judgment experience of testing personnel, and ensures the requirements of product quality.

Owner:奥新(厦门)轴承有限公司

Constraint type experiment supercavity generating device

InactiveCN103257030BQuick and accurate disconnectionAccurately Stabilize CavitationHydrodynamic testingEngineeringOrganic glass

The invention discloses a constraint type experiment supercavity generating device. The front face and the rear face of a water tank are provided with organic glass windows. A through groove is formed in the middle of the upper face of the water tank in the length direction. Two Z-shaped guide rails which are oppositely arranged are installed on the water tank. A sliding pair is formed by a bearing sliding block and the guide rails. One end of a connecting rod is connected with the bearing sliding block and the other end of the connecting rod is provided with an experiment model which extends into the water tank. One end of a steel wire is connected with the bearing sliding block and the other end of the steel wire is connected with a winching wheel in a dragging device. The two guide rails close to one side of the dragging device are respectively provided with a sliding strip. A revolute pair is formed by one end of each sliding strip and one guide rail respectively through a rotary shaft. The side faces of the two guide rails are respectively provided with an adjusting screw. Two pressure sensors are arranged on the guide rails respectively. A high-speed camera and a lighting lamp are arranged in front of one window. The high-speed camera is connected with an industrial control computer. Supercavity generation and development processes around the experiment model are shot through the high-speed camera and accurate and stable experiment speed within a certain range is offered to different models.

Owner:ZHEJIANG SCI-TECH UNIV

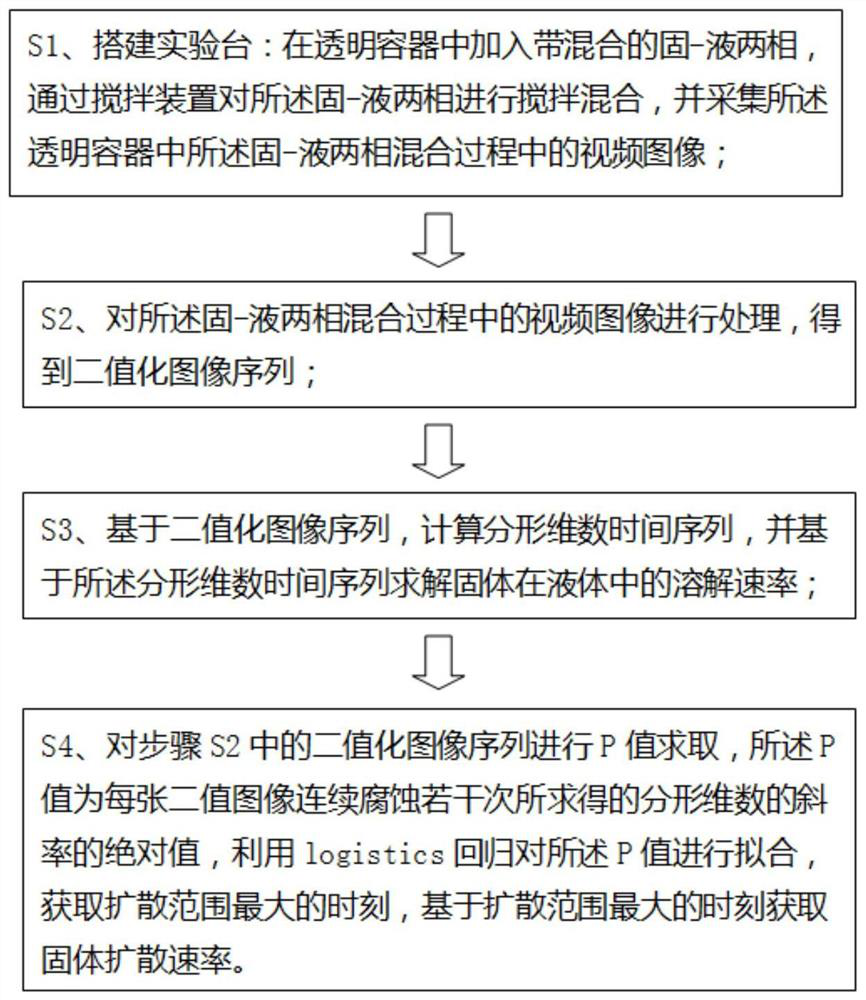

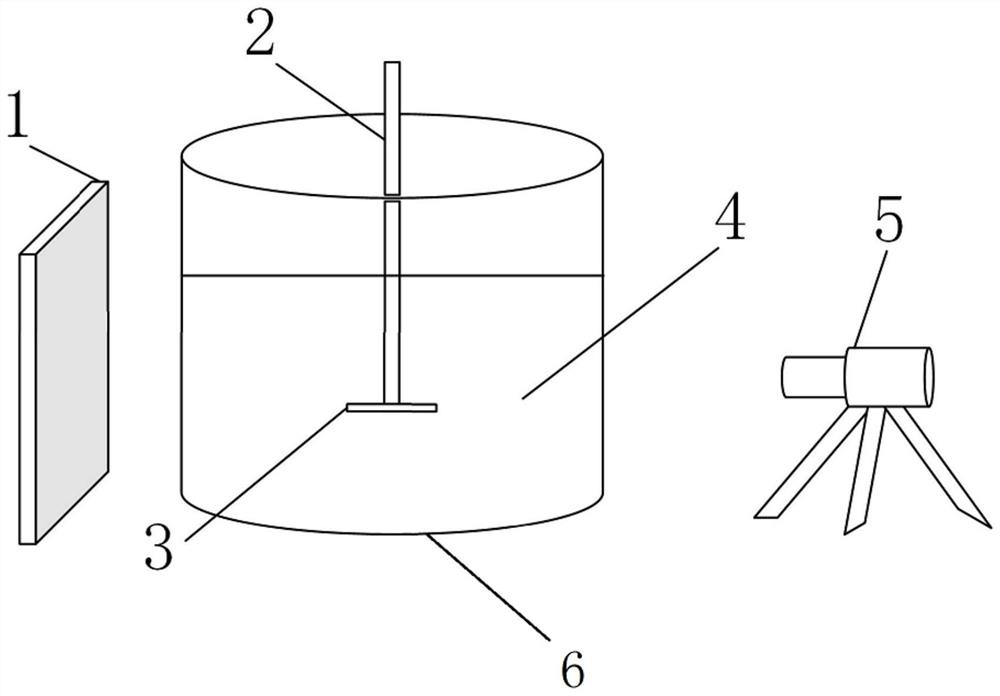

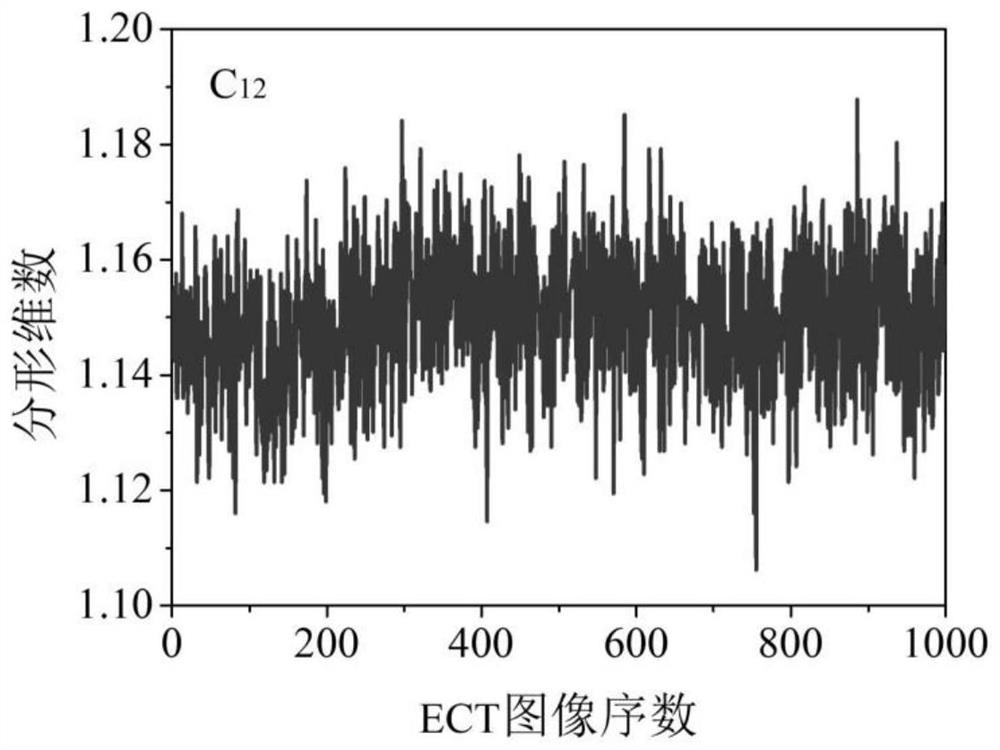

Method for measuring solid diffusion rate and dissolution rate in solid-liquid mixing process

ActiveCN113138141AIntuitive and accurate measurementImprove applicabilityDiffusion analysisBinary imagePhase mixing

The invention discloses a method for measuring a solid diffusion rate and a dissolution rate in a solid-liquid mixing process, which comprises the following steps: S1, building an experiment table: adding a solid-liquid phase to be mixed into a transparent container, stirring and mixing, and collecting a video image in the solid-liquid phase mixing process; S2, processing the collected video image to obtain a binary image sequence; S3, calculating a fractal dimension time sequence based on the binary image sequence, and solving the dissolution rate of the solid in the liquid based on the time sequence; and S4, obtaining a P value of the binary image sequence, the P value being an absolute value of the slope of the fractal dimension obtained by continuously corroding each binary image for a plurality of times, fitting the P value by utilizing logistic regression, obtaining a moment when the diffusion range is maximum, and obtaining the solid diffusion rate based on the moment when the diffusion range is maximum. According to the invention, the solid diffusion rate and the dissolution rate in the solid-liquid mixing process can be measured in a non-invasive, intuitive and accurate manner.

Owner:KUNMING UNIV OF SCI & TECH

A Dimensionality Reduction Monitoring Method for Random Multidimensional Vibration of Aircraft Model

ActiveCN112033636BIntuitive and accurate multi-dimensional vibrationIntuitive and accurate measurementAerodynamic testingVertical planeFlight vehicle

Owner:DALIAN UNIV OF TECH

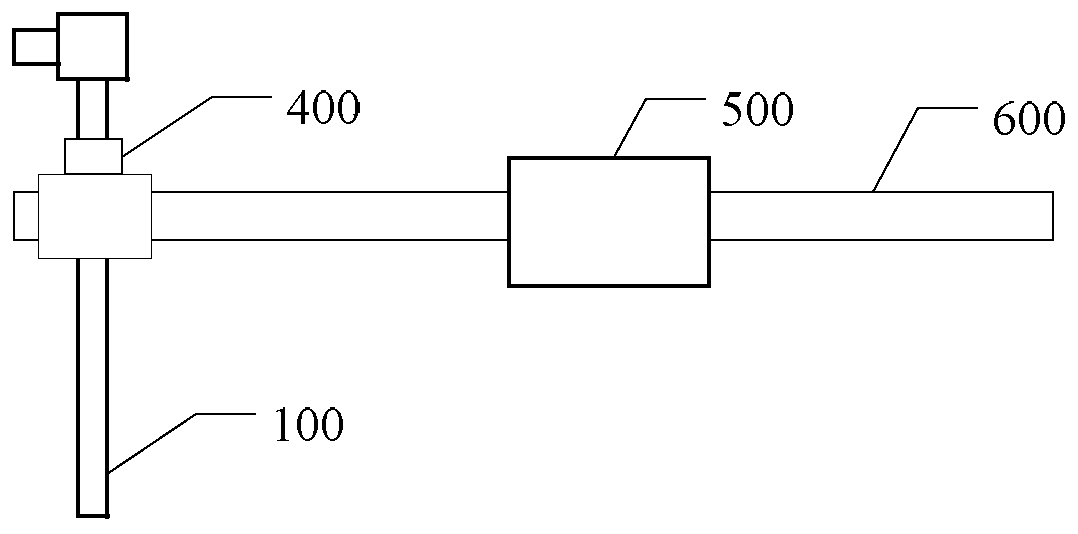

Lens laser focus-measuring device

ActiveCN101290264BEasy to operateIntuitive and accurate measurementTesting optical propertiesLaser transmitterEngineering

The invention relates to a laser focusing device for a lens during the process of manufacturing a stage lamp, comprising a guide rail, a first slide carriage, a second slide carriage and a third carriage which are arranged on the guide rail; one side of each slide carriage is respectively provided with a fixing button, so that each slide carriage can slide and be fastened on the guide rail; the third slide carriage is provided with an L-shaped support having an upper end provided with a laser emitter module which is provided with a laser; the second slide carriage is provided with a lens support above which a lens is arranged; and the first slide carriage is provided with an L-shaped support having an upper end provided with a laser receiver module which is provided with a laser receiver.The device has the advantages of convenient and simple operation, accurate and direct measurement, low cost, simplified calculation during the designing process, reduced error, improved work efficiency, and accurate measurement for both spherical lens and non-spherical lens.

Owner:BEIJING XINGGUANG FILM & TV EQUIP TECH CO LTD

Method for determining hydrophobicity migration of silicone rubber umbrella skirt

PendingCN113848157AIntuitive and accurate determination of hydrophobicity mobilityIntuitive and accurate measurementDiffusion analysisPolymer chemistryEngineering

The invention relates to a method for determining hydrophobicity migration of silicone rubber umbrella skirts, which comprises the following steps: selecting various silicone rubber umbrella skirts with different formulas, different processes and different umbrellas, carrying out artificial aging on the silicone rubber umbrella skirts for 500 hours, washing off dirt on the surfaces of the silicone rubber umbrella skirts, then taking imitated natural dirt for dirt coating, selecting a plurality of brand-new silicone rubber umbrella skirts which are not artificially aged for 500 hours and have different formulas, different processes and different umbrellas for coating, and then carrying out hydrophobicity experiments on the first to-be-tested silicone rubber umbrella skirt and the second to-be-tested silicone rubber umbrella skirt; so that the hydrophobic migration performance change condition of the silicone rubber umbrella skirt before and after 500-hour artificial aging can be intuitively and accurately judged, and the silicone rubber material suitable for the silicone rubber umbrella skirt in the southern coastal area can be selected. compared with the prior art, the method has the advantages that the hydrophobicity experiment is not directly carried out after 500 hours of artificial aging, the adverse influence of environmental factors can be eliminated, and the hydrophobicity migration of the silicone rubber umbrella skirt can be intuitively and accurately measured.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

An experimental device for visualizing the mechanical properties of hydrate wall adhesion and its working method

ActiveCN107024428BEliminate conditionalityIntuitive and accurate measurementPreparing sample for investigationUsing mechanical meansAdhesion forceMicroscopic observation

The invention relates to a visual experiment device of wall adhesion mechanical properties of hydrate and a working method of the visual experiment device. The visual experiment device comprises a circulating refrigeration system, a testing unit system, a microcosmic operation system and a microscopic observation system, wherein the testing unit system comprises a normal-pressure visual reaction device, a normal-pressure reaction groove, a liquid inlet, a liquid outlet and a testing unit element; the normal-pressure reaction groove is arranged on one side wall of the visual reaction device; the liquid inlet and the liquid outlet are formed in the side wall in a communicating manner; a visual window is further arranged on the side wall; the testing unit element is arranged in the normal-pressure reaction groove; the testing unit element comprises a solid metal block and transparent quartz frames; a plurality of transparent quartz frames are arranged on the solid metal block. By adopting the visual experiment device provided by the invention, generation, growth and deposition conditions of cyclopentane hydrate on a wall can be researched and monitored relatively well, and condition limitation that the hydrate only can be generated under a high-pressure environment is eliminated, so that an adhesion force of the cyclopentane hydrate generated on the wall is more accurately and directly measured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Measuring device for deep subsidence of soil mass and its application method

The invention discloses a device for measuring deep settlement of soil and a using method of the device. The device for measuring deep settlement of the soil comprises a settlement plate sleeve, an upper steel plate, a lower steel plate, a first gear, at least two second gears, an extending rod, at least two metal rods and at least two settlement fan blades. The second gears are rotatably arrangedbetween the upper steel plate and the lower steel plate, and the first gear is engaged with the second gears. The metal rods correspond to the second gears one by one, the upper ends of the metal rods are fixed to the centers of the lower surfaces of the corresponding second gears, and the lower ends of the metal rods go downwards vertically and sequentially penetrate through the lower steel plate and the lower end of the settlement plate sleeve. The settlement fan blades correspond to the metal rods one by one, one ends of the settlement fan blades are perpendicularly connected to the lowerends of the corresponding metal rods. The device has the advantages of being low in cost, accurate in measure, capable of being recycled and the like, and can be widely applied to equipment and the technical field for measuring deep settlement of the soil.

Owner:中交二航局建筑科技有限公司

The Method of Using Standard Thickness Weight to Detect the Height of Grouting Sleeve Inner Grouting Surface

The invention provides a method for detecting the height of the slurry surface inside a grouting sleeve by using a standard thickness weight, wherein the method uses a device for detection. The devicecomprises standard weights (1), a connecting line (2), and a weight tube (3). To be specific, the method comprises: connecting the connecting line (2) to one standard weight (1)fixedly and to other weights in series, arranging the connection part at the front end of the weight tube (3), and holding a connecting end or connecting the connecting end fixedly by a fixed support device and leading theweights out of a to-be-detected grouting sleeve though a slurry outlet hole till exceeding the slurry outlet hole of the sleeve by the weights, and indicating the unfilling height of the grouting sleeve according to the led weight thickness sum and a scale displayed by a last weight. The method is accurate and simple and is easy to operate.

Owner:湖南新懋旭科技有限公司

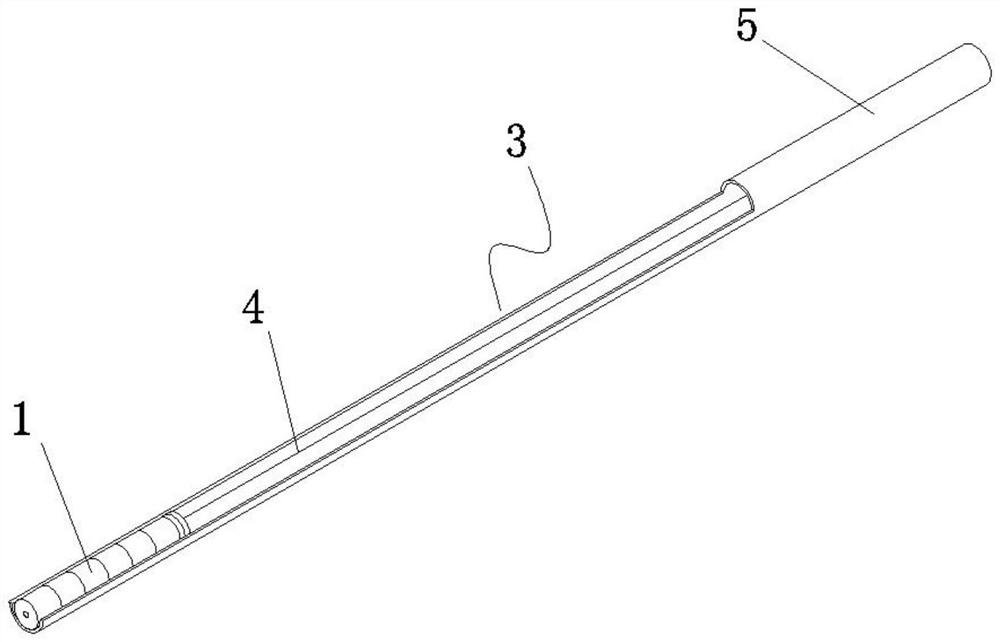

Conventional drill hole injection molding track positioning and measuring method under coal mine

InactiveCN109667572AWide range of hardnessReduce waiting timeSurveyThermoplastic elastomerHigh pressure

The invention relates to a conventional drill hole injection molding track positioning and measuring method under a coal mine, which is applicable to the measurement of a conventional extraction drillhole track under the coal mine. An experiment system device comprises an injection molding extrusion machine, a thermoplastic elastomer (TPE) material raw material, a hose pipe mould and a high-pressure pump; the injection molding extrusion machine is used for heating the TPE material raw material; the hose pipe mould is placed in an extraction drill hole so as to be used for molding the TPE material; and the high-pressure pump is used for pressurizing a injection molding extrusion process. By using the conventional drill hole injection molding track positioning and measuring method under thecoal mine involved in the invention, the conventional drill hole track under the coal mine can be measured and described, so that a track measuring step is simplified, and the track measuring efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A method for detecting biological activity of recombinant human keratinocyte growth factor

ActiveCN106226511BPromote proliferationIntuitive and accurate measurementBiological testingRecombinant Human Keratinocyte Growth FactorCorneocyte

The invention provides a method for detecting recombinant human keratinocyte growth factors (rhKGF-1). The method includes steps of 1), cultivating keratinocytes; 2) inoculating the keratinocytes and controlling the density of the keratinocytes; 3), treating rhKGF-1 samples, carrying gradient dilution on the concentration of the rhKGF-1 samples and adding 5-acetenyl-2'-deoxyuridine (EdU) into the rhKGF-1 samples with various rhKGF-1 concentration dilution degrees to prepare loading samples with the series of rhKGF-1 concentration dilution degrees; 4), washing the keratinocytes in keratinocyte plates obtained at the step 2) and removing cultivation media; 5), loading the loading samples obtained at the step 3) into keratinocyte cultivation plates obtained at the step 4) and cultivating and incubating the keratinocytes; 6), solidifying and permeabilizing the keratinocytes, and then carrying out 'Click-iT' reaction on the EdU; 7), arranging the keratinocytes treated at the step 6) in a multifunctional microplate reader, reading the fluorescence intensity (RFU) and computing the biological activity of the rhKGF-1. The method has the advantages of low detection background, high sensitivity, specificity and accuracy, good repeatability and the like. Besides, the method is particularly applicable to detecting the biological activity of the rhKGF-1 and establishing quality standards.

Owner:信立泰(苏州)药业有限公司

Small end cover end face height guide rail inspection tool

ActiveCN103913104BImprove working precisionReduce manufacturing costMechanical measuring arrangementsEngineeringSpare part

The invention belongs to the field of clamp detection devices, and discloses a small end cap end face height guide rail detection device. The device comprises a bottom plate, wherein the left of the bottom plate is provided with a clamping mechanism, the lower end of the clamping mechanism is provided with a pressing plate, the side edge of the bottom plate is provided with a guide rail where a sliding block is arranged, and the sliding block is provided with a non-go gauge and a go gauge. According to the small end cap end face height guide rail detection device, in terms of the principle of the non-go gauge and the go gauge, the detection process is visual, detection efficiency is high, the error rate is low, the device has no requirements for techniques of operators, manual operation is facilitated, fatigue is not prone to occurrence, work precision of the detection device is high, manufacturing cost is low, the device is easy to manufacture and machine, spare parts are easy to replace, and interchangeability is high.

Owner:CHANGSHA BODA MACHINERY PARTS CO LTD

Digital Microscope Wear Spot Measuring Device

ActiveCN104020044BAvoid measurement errorsRealize integrationStrength propertiesMeasurement deviceOptical axis

The invention relates to a digital microscope wear scar measurement device and belongs to the field of four-ball friction testing machine detecting equipment. The digital microscope wear scar measurement device comprises a bottom plate seat, a supporting beam, a fine thread supporting rod, a working platform, a digital microscope and a cylinder oil box base, wherein the bottom plate seat is composed of a seat body and a bottom plate, and the working platform is matched with the bottom plate in a sliding manner and provided with a sliding limiting block; the cylinder oil box base is arranged on the working platform in a manner that the axial lead of the cylinder oil box base has an included angle of 54 degrees with the working platform; the fine thread supporting rod is fixedly connected with the seat body, and the lifting of the supporting beam is adjusted relative to the fine thread supporting rod through an embedded nut of the supporting beam; two strong magnet pieces are arranged in two counter bores in one side in the supporting beam; the optical axis of the digital microscope has an included angle of 36 degrees with the axis of the cylinder oil box base, and the digital microscope is vertically connected to a connecting arm of the supporting beam. The digital microscope wear scar measurement device ensures the accurate centering and high-precision fine-tuning focal length of the working platform and provides quick and accurate observation and measurement for the wear scar detection of four-ball friction testing machines.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com