A method for measuring the outer spherical surface of a bearing

A measurement method and outer spherical technology, applied in mechanical counter/curvature measurement and other directions, can solve problems such as difficulty in meeting product requirements and large errors, and achieve the effect of guaranteeing requirements, accurate and intuitive measurement, and convenient measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

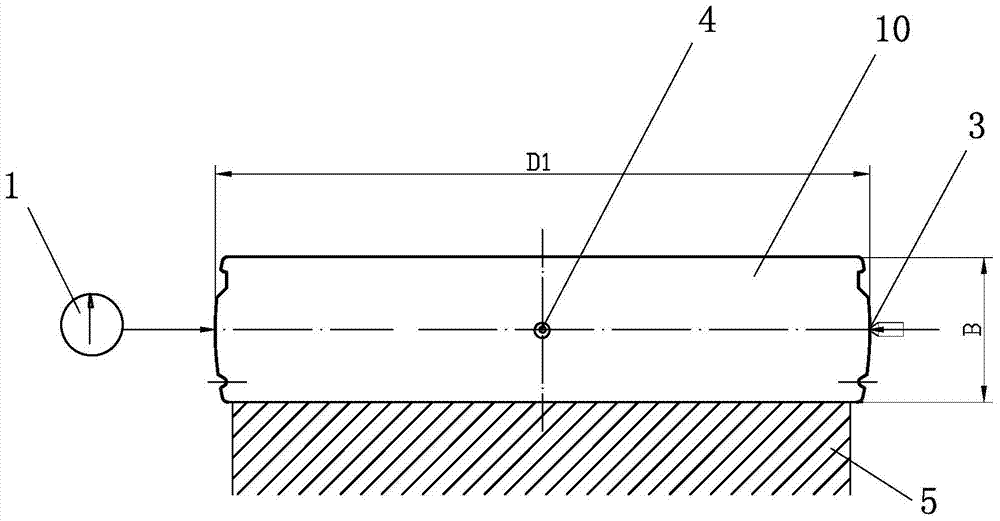

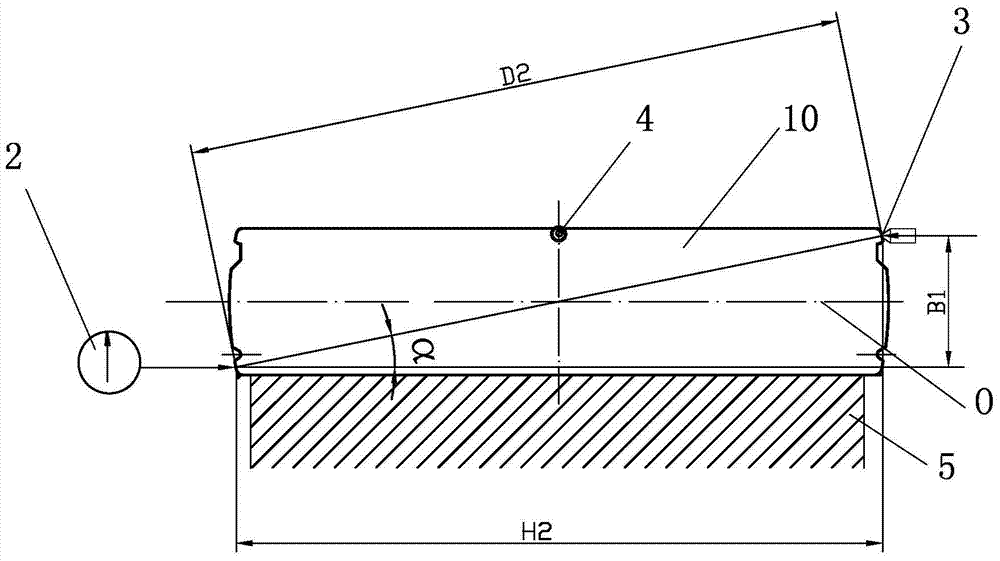

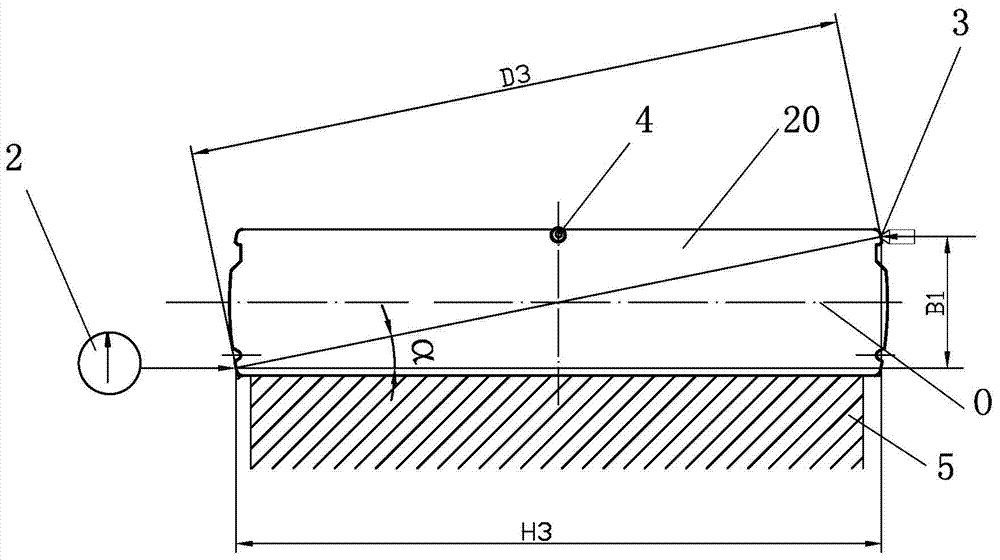

[0020] Such as figure 1 with figure 2 As shown, a method for measuring the outer spherical surface of a bearing is to detect the spherical diameter of the UC207 product, and the spherical size requirement is ф The test includes the following steps:

[0021] (1) Select standard parts from the finished products of this model, measure and mark the ball diameter D1 at the midpoint in the width direction of the standard part and the ball diameter D2 at the opposite corner. The spherical size of the selected standard part is close to the center of the tolerance zone, which is ф71. Around 994mm;

[0022] (2), such as figure 1 As shown, the lower end surface of the standard part 10 is placed on a horizontal spacer block 5, the lower end surface of the standard part 10 and the upper surface of the spacer block 5 are level, the axis of the standard par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com