Tank Siltation Measuring Device

A technology of measuring devices and water tanks, which is applied in measuring devices, lubrication indicating devices, liquid/fluid solid measurement, etc., can solve the problems of power waste of equipment and materials, physical injury of operators, and traditional and primitive methods, etc., to improve service life, Effect of reducing work intensity and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

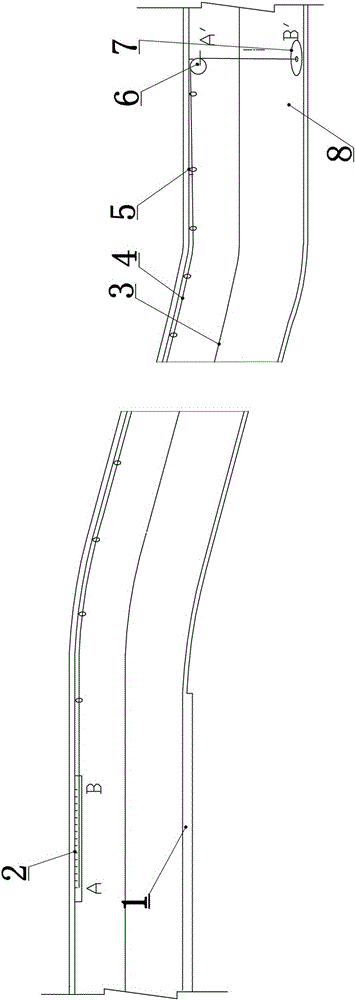

[0022] like figure 1 The installation diagram of the present invention shown. To achieve the above object, the technical solution adopted in the present invention is:

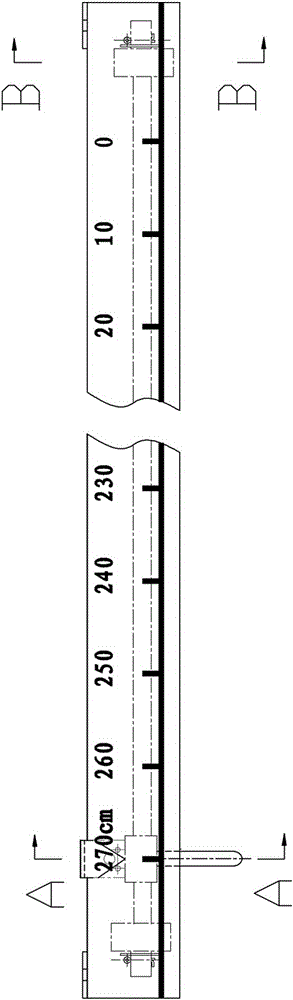

[0023] 1. The length AB of the measuring scale 2 = the stroke A'B' of the pendant 7, that is, the length of the measuring scale is equal to the height of the roadway of the water tank.

[0024] 2. The normal device is kept at point AA', that is, the measuring slider 17 is fixed at point A, and the pendant 7 is at the top.

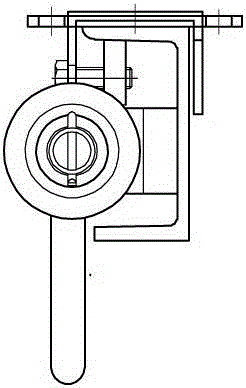

[0025] Nylon rope fixes a sign arrow (measurement slide block 17) at A point, utilizes the steel plate dead weight of pendant 7 to make A point arrow slide to B point direction on the nylon rope along a straight line during measurement.

[0026] 3. If figure 1 shown. When the weight 7 slipped to the upper plane of the deposit, the nylon rope was the stay cord 4 and stopped slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com