Conventional drill hole injection molding track positioning and measuring method under coal mine

A technology of trajectory positioning and measuring method, which is applied in the directions of surveying, earth-moving drilling, wellbore/well components, etc., can solve the problems of high cost of positioning the drill bit, high requirements on experimental conditions, complicated operation, etc., and achieves wide practicability, measurement Intuitive, accurate and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

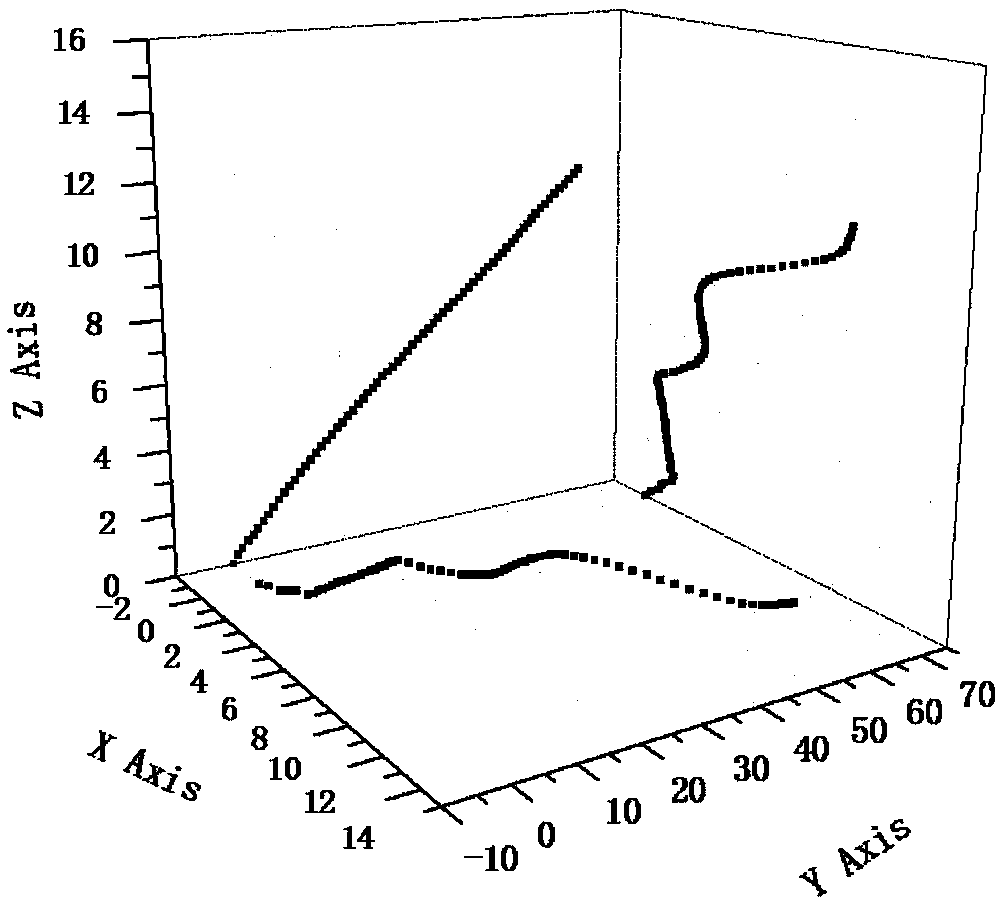

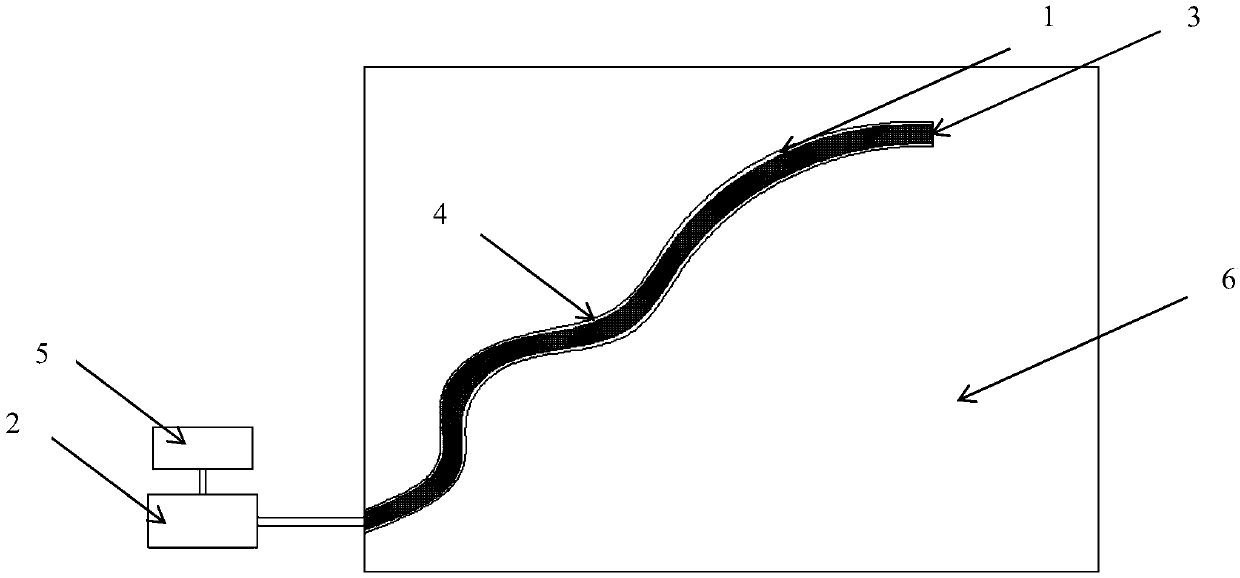

[0016] The injection molding trajectory positioning test system for underground conventional drilling in coal mines of the present invention is composed of an injection molding extruder (2), a TPE material raw material (3), a hose mold (4) and a high-pressure pump (5).

[0017] The method for positioning and testing the trajectory of conventional drilling injection molding in underground coal mines of the present invention has the following specific steps:

[0018] a. After withdrawing the extraction drill pipe, clean the inside of the borehole (1) to prevent debris from clogging the borehole;

[0019] b. Slowly insert the closed end of the hose mold (4) into the borehole (1) until it reaches the bottom of the borehole (1);

[0020] c. Connect the high-pressure pump (5) to the injection molding machine (2) through the hose (4), turn on the power supply, and preheat the inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com