Small end cap end face height guide rail detection device

A technology of guide rails and end caps, which is applied in the field of small end cap end face height guide rail inspection tools, which can solve the problems of high error rate in manual measurement, low detection efficiency, time-consuming and labor-intensive, etc., so as to facilitate manual operation, low production cost, and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

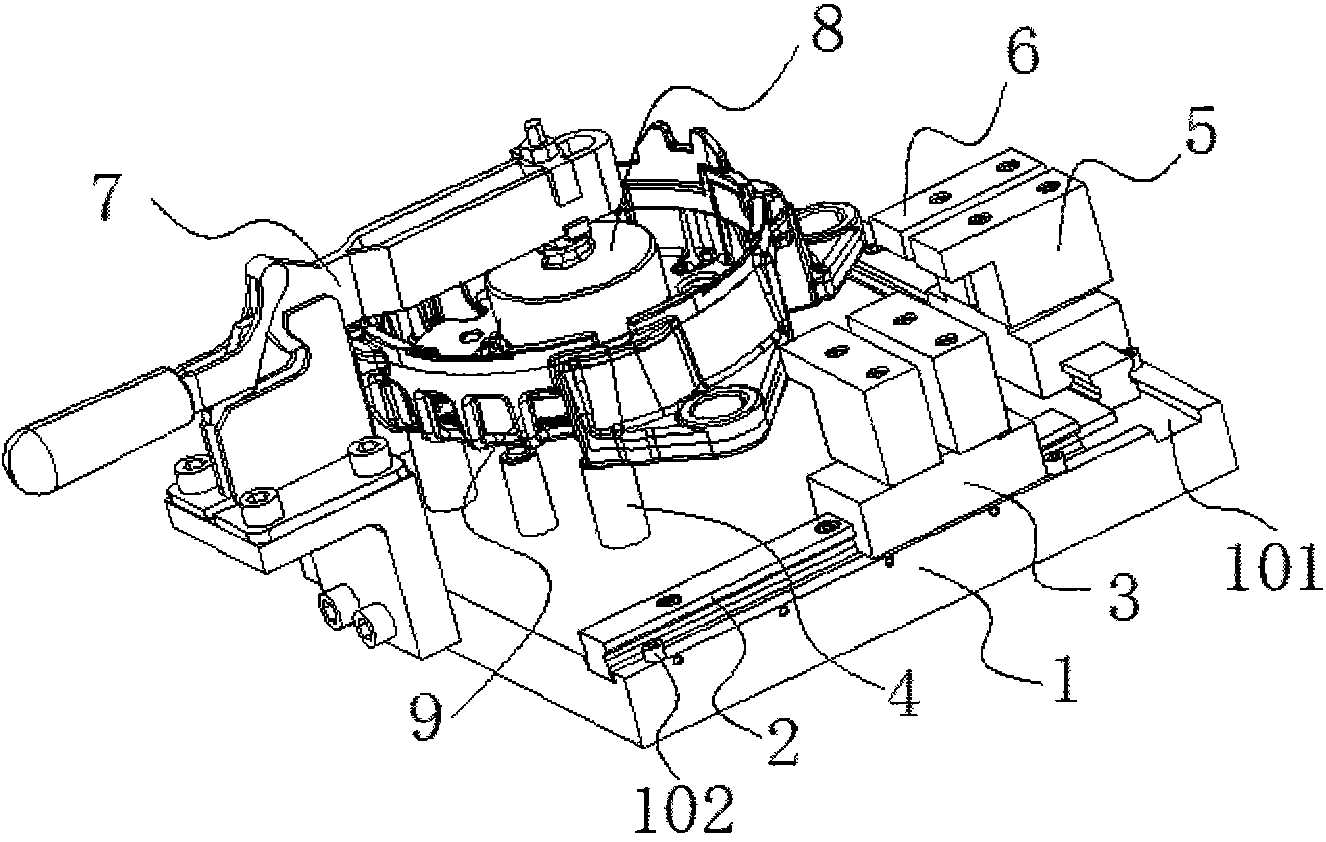

[0026] like Figure 3-4 As shown, the specific structure of the present invention is as follows: it includes a base plate 1, a clamping mechanism 7 is provided on the left side of the base plate 1, a pressing plate 8 is provided at the lower end of the clamping mechanism 7; a guide rail 2 is provided on the side of the base plate 1 , the guide rail 2 is provided with a slider 3 , and the slider 3 is provided with a stop gauge 5 and a through gauge 6 . A positioning column 4 is arranged in the middle of the bottom plate 1 . A guide rail groove 101 is formed on the side of the bottom plate 1 , and the guide rail 2 is fitted in the guide rail groove 1 .

[0027] Preferably, two adjacent sides of the bottom plate 1 are provided with guide rail grooves 101 , and the guide rail grooves 101 are vertically staggered, and the guide rails 2 are fitted therein. A block 102 is provided near the end of the guide rail 2 . The stopper 102 is arranged on the bottom plate 1 near the end of ...

Embodiment 2

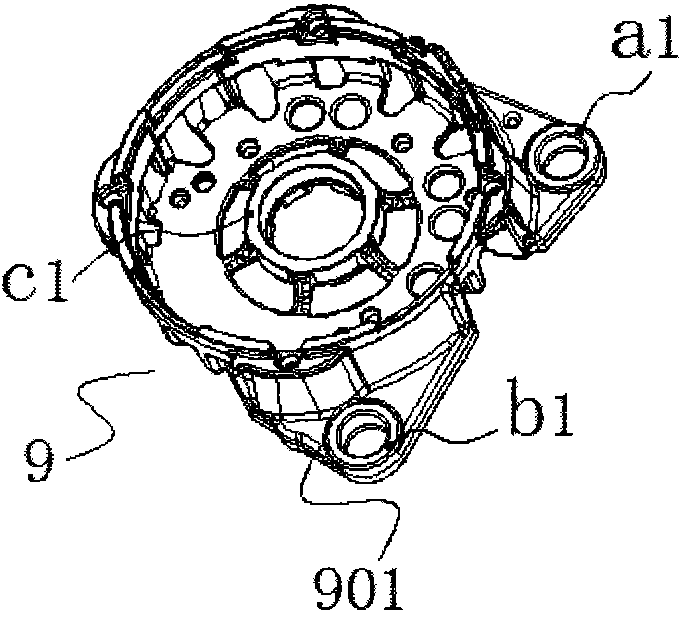

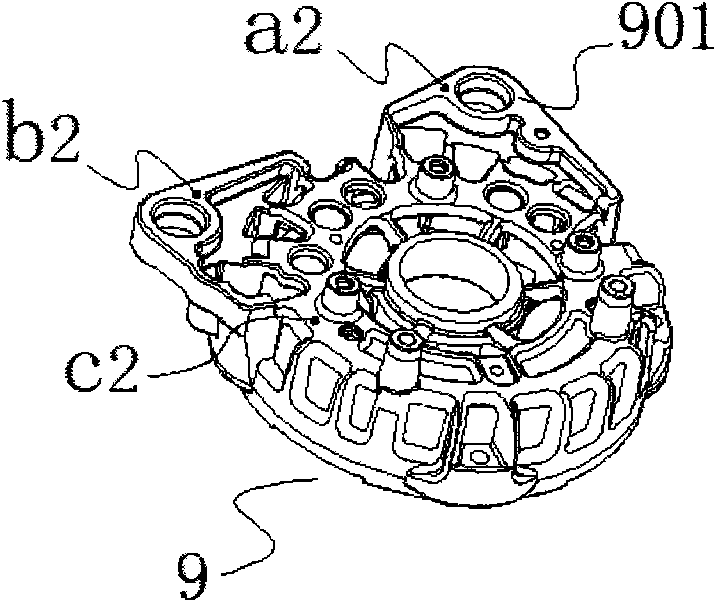

[0030] like Figure 5 As mentioned above, this embodiment follows the basic structure of the previous embodiment. The difference is that the setting of the through gauge 6 and the stop gauge 5 are different. The side of the through gauge 6 is provided with a measuring groove 601, and the height of the stop gauge 5 is lower than that of the through gauge. Gauge 6 height. The measurement mode of Embodiment 1 is to indirectly measure the heights of the a1, b1 surfaces and c2 of the hanging angle 901 of the end cover 9, that is, the height from the plane positioning surface of the end cover 9 to the upper end surface of the hanging angle hole of the hanging angle 901, thereby judging Whether the product is qualified; here embodiment two is the height of the a2, b2 surface and c2 of the hanging angle 901 of the end cover 9 indirectly, that is, the plane positioning surface of the end cover 9 to the lower end surface of the hanging angle hole of the hanging angle 901 Height, in ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com