Method for detecting height of slurry surface inside grouting sleeve by using standard thickness weight

A technique of grouting sleeves and standard weights, which is applied in measuring devices, liquid level indicators, engine lubrication, etc., can solve problems such as difficult operation and control, large error in test results, and high operating requirements, and achieve accurate measurement Intuitive and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

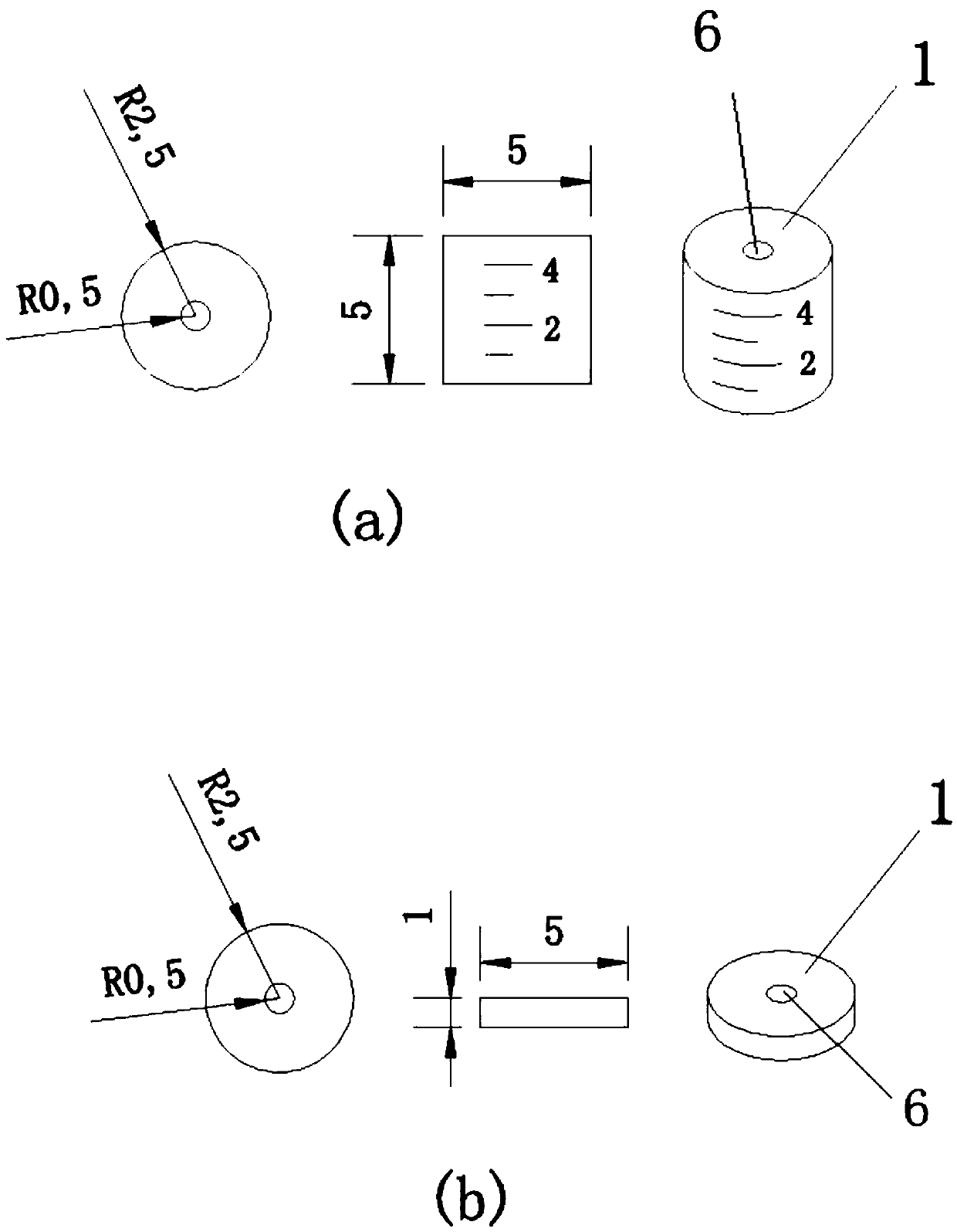

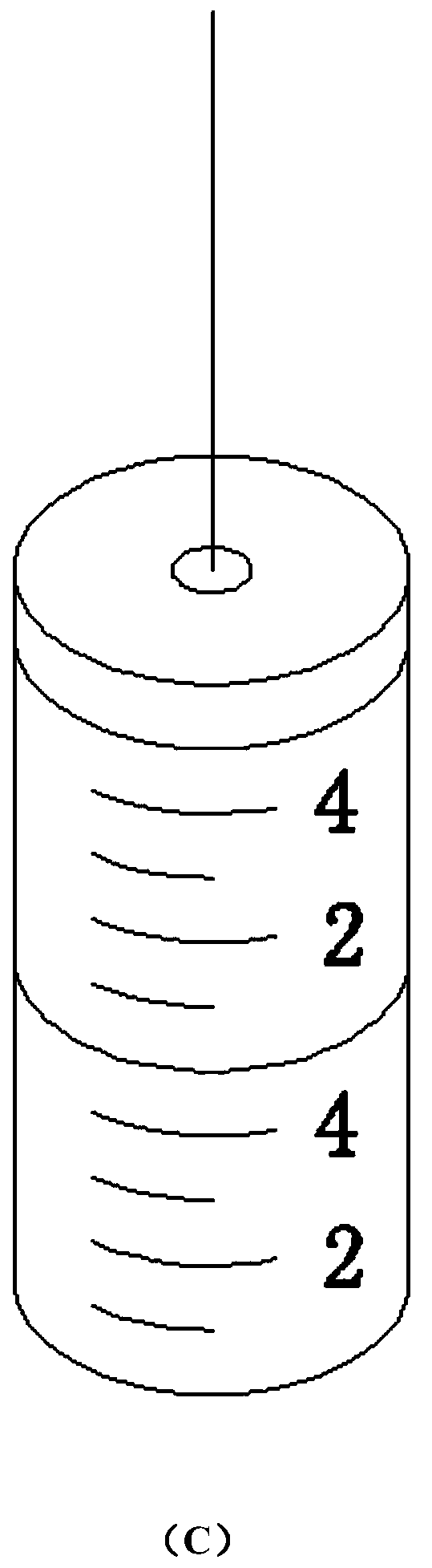

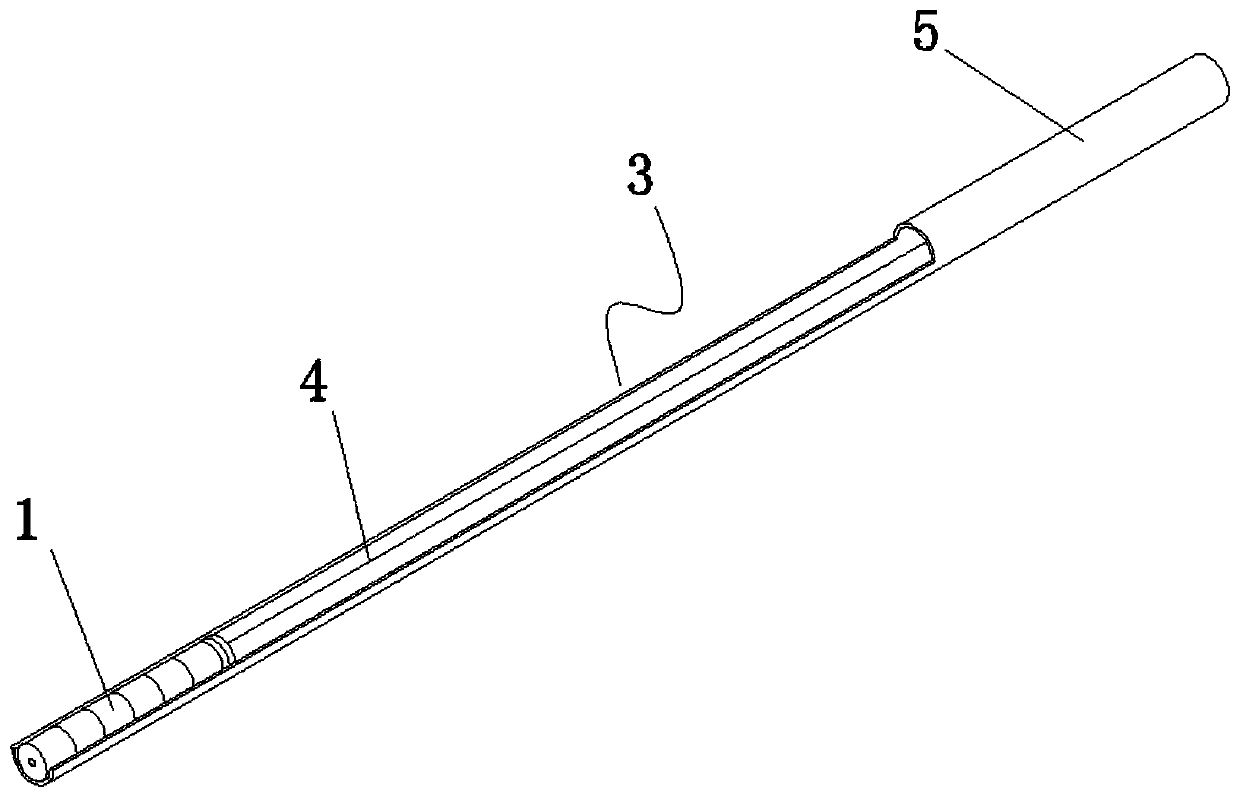

[0043] A device for detecting the height of the slurry surface in a grouting sleeve using a standard thickness weight, the device includes a standard weight 1, a connecting line 2 and a weight conduit 3; the standard weight 1 includes a variety of cylinders with different thicknesses, each There are multiple cylinders of different thicknesses, and the center of the cylinder is provided with a hole 6 for the connecting wire 2 to pass through, and the cylinder is provided with a thickness scale.

[0044] The standard thickness weight described in this embodiment, such as figure 1As shown, the standard thickness weight is processed into a cylinder with (stainless) steel plate, the diameter of the cylinder is 5mm, and there are two specifications for the thickness (or height) of the cylinder, one is the weight with a thickness (or height) of 5mm , and the other is a weight with a thickness (or height) of 1 mm. A round hole with a diameter of 1 mm is opened along the vertical cente...

Embodiment 2

[0048] The device method of using standard thickness weights to detect the height of the slurry surface in the grouting sleeve uses the device of Example 1, the rear end of the conduit is connected to the magnetic table base, and the magnetic table base includes a vertical wall connected to the magnetic base 7 and the magnetic base. The connecting rod 8 and the direction adjusting rod 9 connected with the vertical connecting rod; the connecting end 5 of the weight conduit 3 is connected with the direction adjusting rod 9 of the magnetic watch stand.

[0049] Use connecting line 2 to be fixedly connected with a weight with a thickness of 5mm, and then connect other weights in series, as for the front end of the catheter.

[0050] Use the catheter to first introduce the 5mm standard thickness weight into the grouting sleeve. If the last 5mm standard thickness weight exceeds the grout outlet hole of the sleeve, you can directly read the scale of the 5mm standard thickness weight t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com