Digital microscope wear scar measurement device

A technology for digital microscopes and measuring devices, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems of too large diameter of the objective lens barrel, inability to quickly locate wear spots, and great influence on accuracy, and achieves simple structure and imaging. Convenient and fast, the effect of expanding the size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

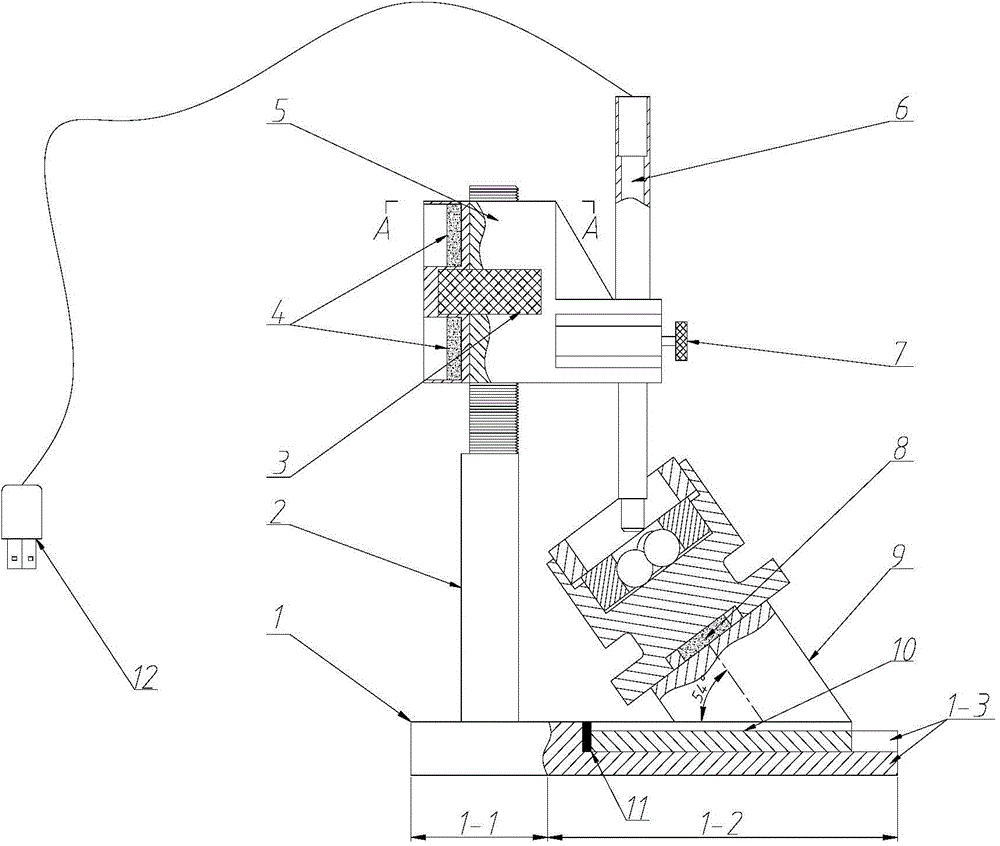

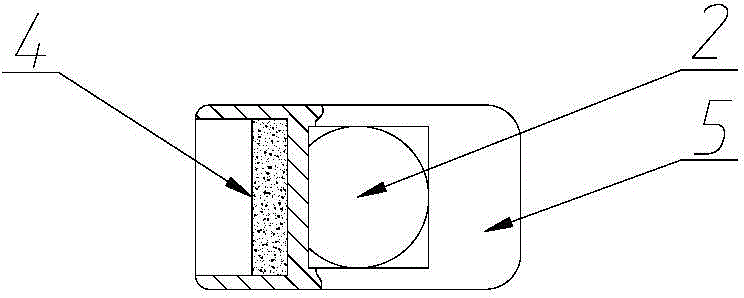

[0013] The digital microscope wear scar measuring device of the present invention comprises a base plate base 1, a support beam 5, a fine thread support rod 2, a working platform 10, a digital microscope 6, and a cylindrical oil box base 9, and the base base base consists of a base body 1-1 It is composed of the base plate 1-2, the base plate 1-2 is provided with a slide rail groove 1-3, and a limit rubber pad 11 is provided between the slide rail groove 1-3 and the inner end surface of the seat body 1-1; the cylinder oil box base The axis line of 9 and the working platform form an angle of 54° and are set on the working platform 10. Through the cooperation of the working platform and the slide rail groove 1-3, the oil box is driven to move to the limit rubber pad 11 at the inner end for positioning; the fine thread The support rod 2 is connected and fixed with the base 1-1 by screws, the support beam 5 is in surface contact with the fine thread support rod 2, and the support b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com