An experimental device for visualizing the mechanical properties of hydrate wall adhesion and its working method

A technology of mechanical properties and experimental devices, applied in the direction of measuring devices, mechanical devices, and preparation of test samples, can solve problems such as danger, low degree of visualization, and pipeline blockage, and achieve accurate and intuitive measurement, high degree of visualization, and eliminate The effect of conditioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

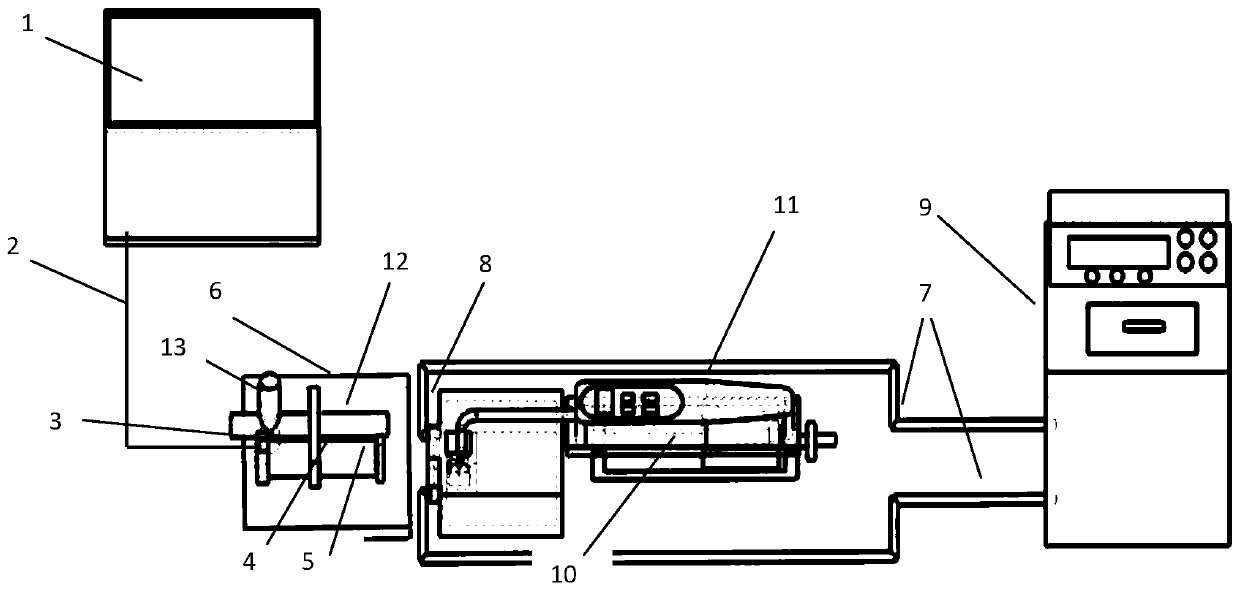

[0050] An experimental setup to visualize the mechanical properties of hydrate wall adhesion, such as figure 1 As shown, it includes a circulating refrigeration system, a test unit system, a microscopic operating system, and a microscopic observation system; the circulating refrigeration system is connected to the test unit system to provide a constant temperature for the test unit system; the microscopic operating system is connected to the test unit system for real-time Measuring the adhesion force of hydrate formed in the test unit system; the microscopic observation system is connected to the test unit system to record the growth of hydrate in the test unit system in real time, present the captured images in real time, and record and store them;

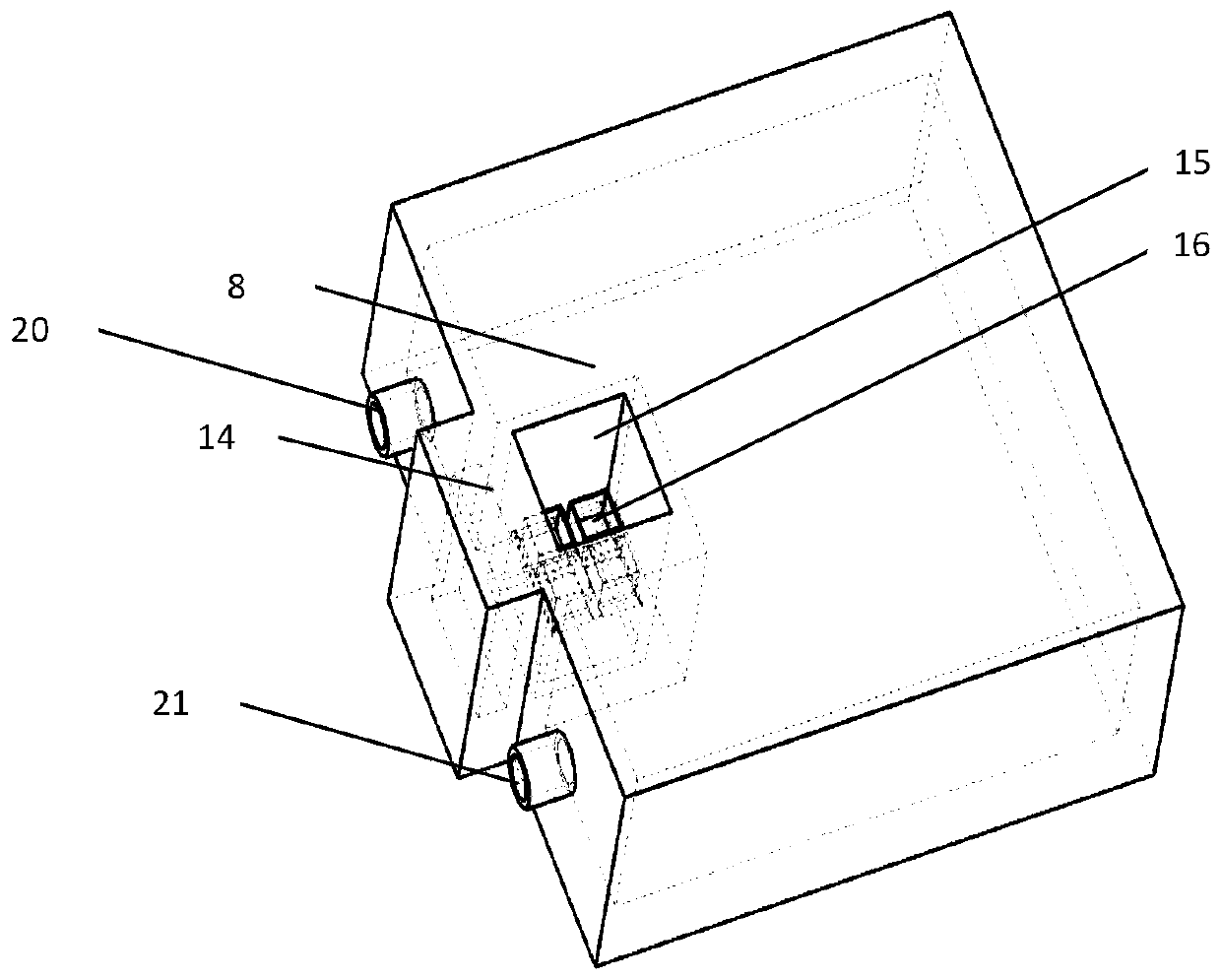

[0051] The test unit system includes a normal pressure visual reaction device 8, a normal pressure reaction tank 15, a liquid inlet 20, a liquid outlet 21, and a test unit 16. The visual reaction device 8 is made of 316L stainless...

Embodiment 2

[0061] The method for obtaining the form of visualized hydrate wall formation and wall adhesion by the device described in Example 1 includes the following steps:

[0062] (1) Inject circulating fluid ethylene glycol into the normal pressure visualization reaction device 8;

[0063] (2) start the circulating refrigeration system, make the temperature in the normal pressure visualization reaction device 8 be adjusted to T 1 ,T 1 = -3°C;

[0064] (3) pour into normal pressure reaction tank 15 Volume of cyclopentane, cooling for 30min;

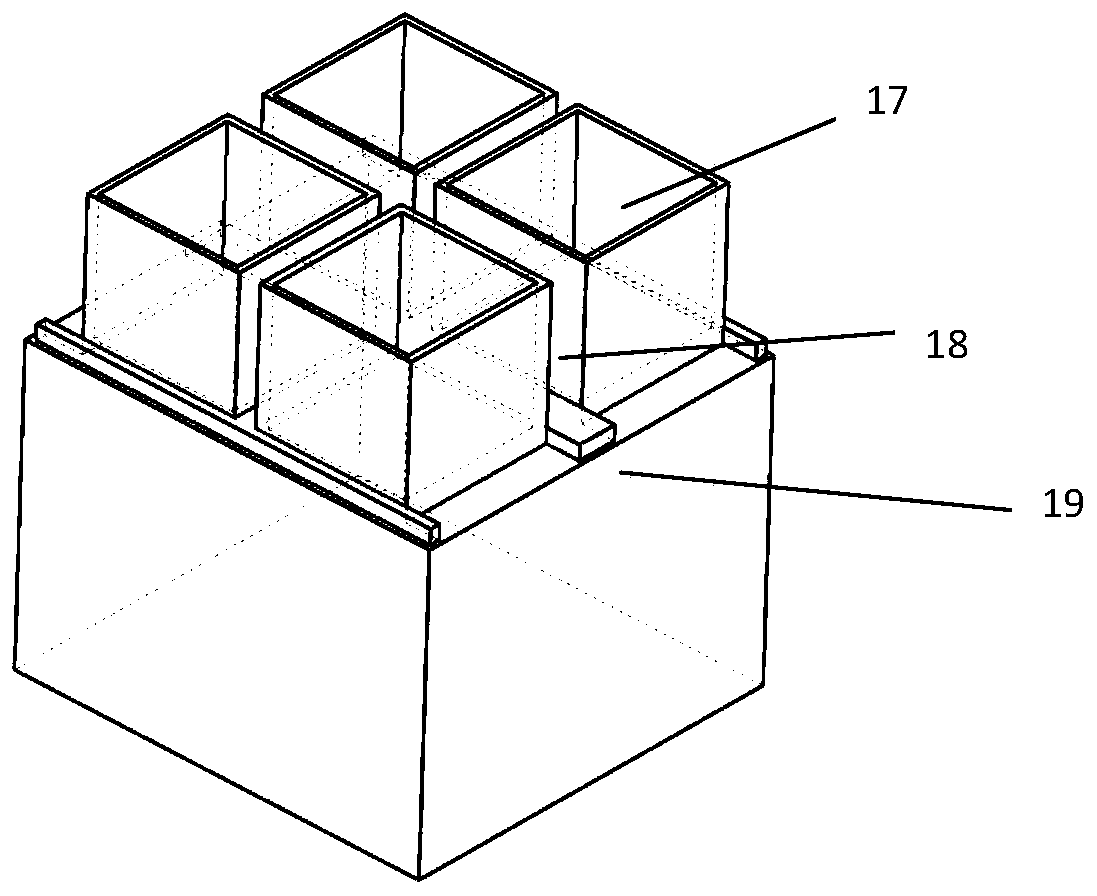

[0065] (4) Submerge the solid metal block 19 in liquid nitrogen to cool for 5 minutes. After the solid metal block 19 is completely cooled, utilize the condensation of distilled water vapor to generate a layer of snow-white ice film on the cooled solid metal block 19 wall surface. Two transparent quartz frames 17 are arranged on the solid metal block 19 through the slot 18, and the solid metal block 19 with four transparent quartz frames 17 ...

Embodiment 3

[0072] The method for obtaining the form of visualized hydrate wall formation and wall adhesion by the device described in Example 1 includes the following steps:

[0073] (1) Inject circulating fluid ethylene glycol into the normal pressure visualization reaction device 8;

[0074] (2) start the circulating refrigeration system, make the temperature in the normal pressure visualization reaction device 8 be adjusted to T 1 ,T 1 = -10°C;

[0075] (3) pour into normal pressure reaction tank 15 Volume of cyclopentane, cooling for 20min;

[0076] (4) Submerge the solid metal block 19 in liquid nitrogen to cool for 5 minutes. After the solid metal block 19 is completely cooled, utilize the condensation of distilled water vapor to generate a layer of snow-white ice film on the cooled solid metal block 19 wall surface. Two transparent quartz frames 17 are arranged on the solid metal block 19 through the slot 18, and the solid metal block 19 with four transparent quartz frames 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com