Flow pipe for the turbulence generator of the headbox of a fibre web machine and a turbulence generator of the headbox of a fibre web machine

A technology of fiber web machines and turbulence generators, applied in the field of turbulence generators, can solve the problems of large module size, difficulty in changing turbulence generators, flow distribution cannot be changed in small proportions, etc., to achieve the goal of reducing or increasing the number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

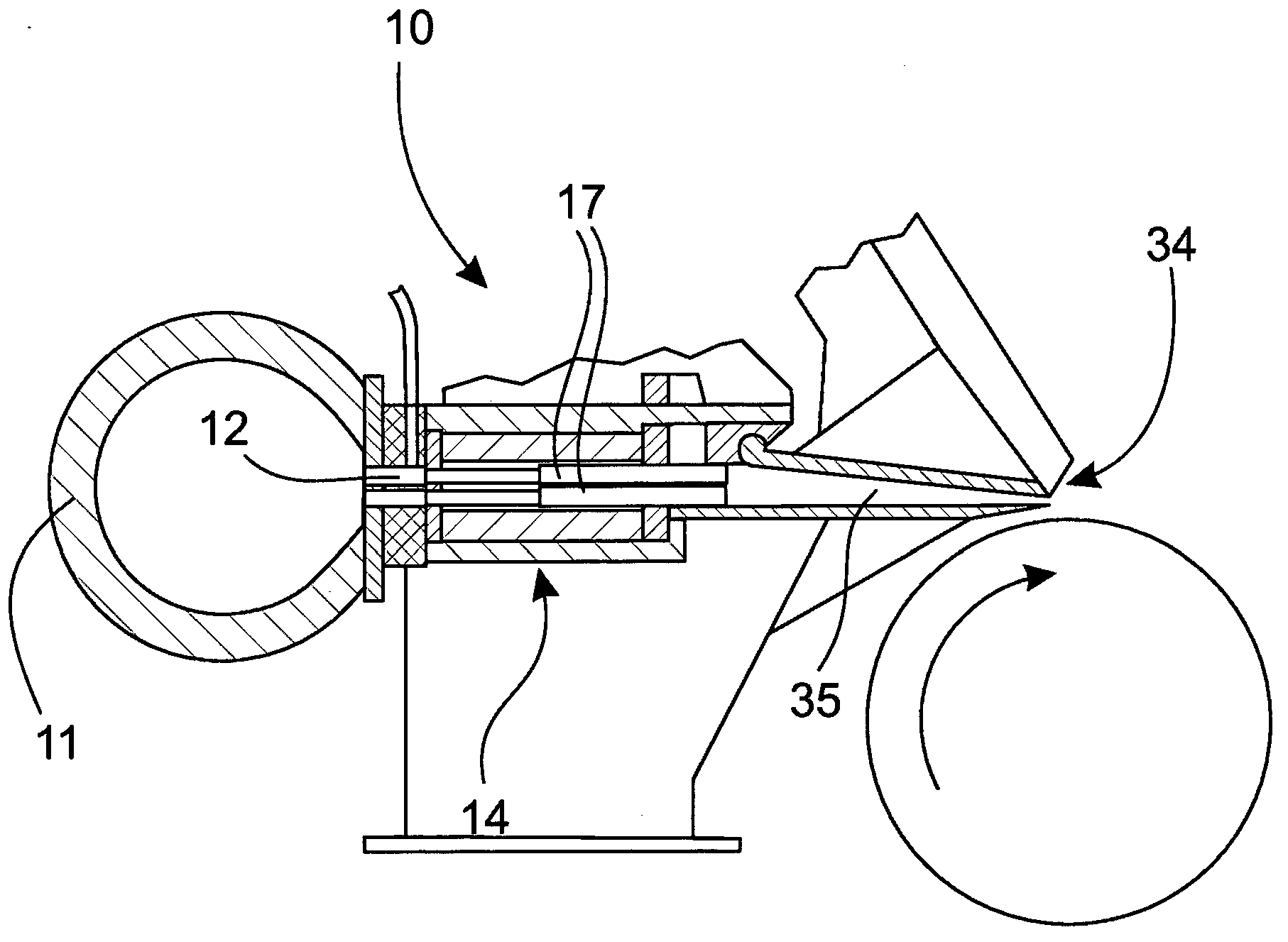

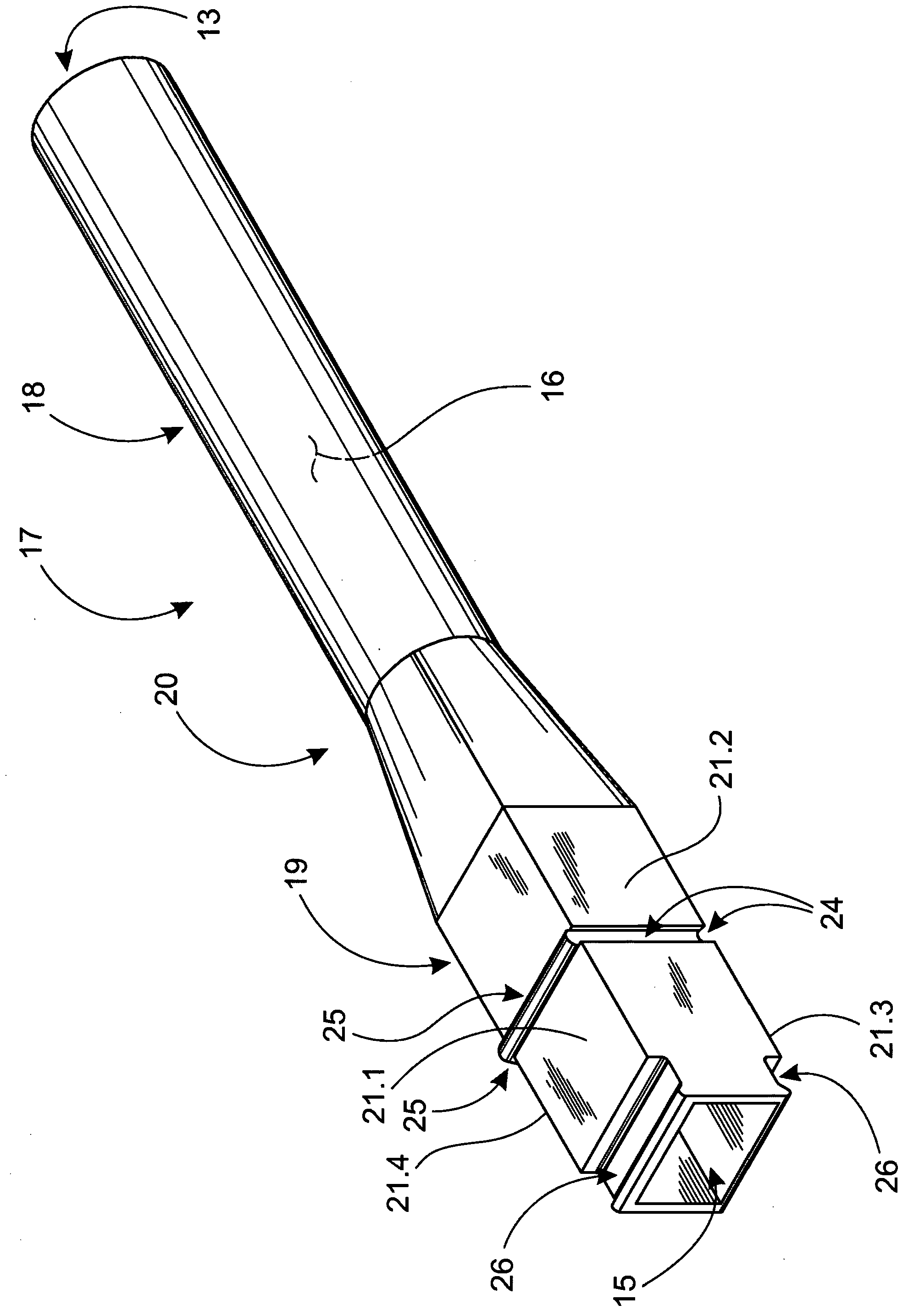

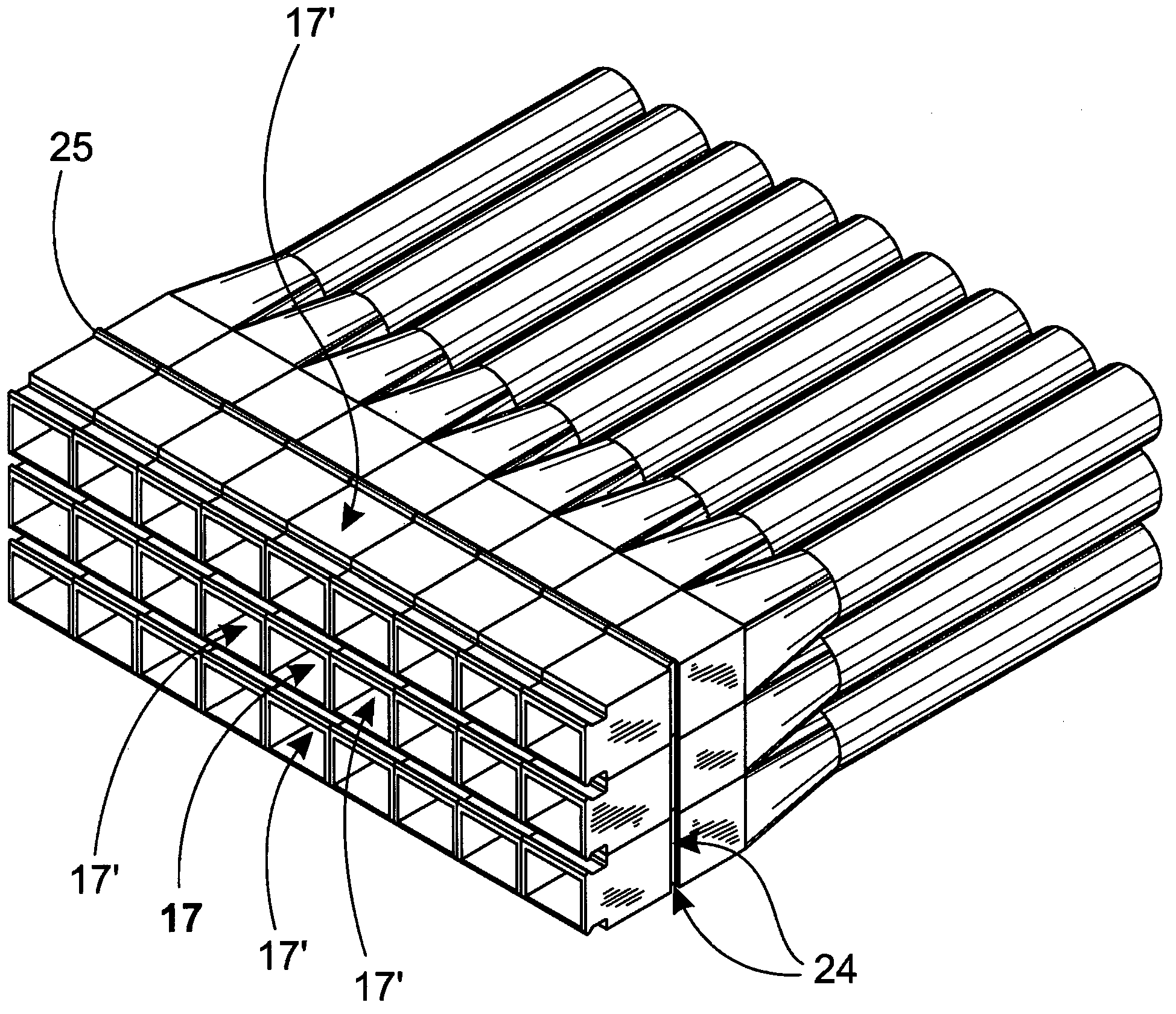

[0021] figure 1 A rough schematic sectional view of an example of a headbox 10 of a fiber web machine is shown viewed from the side. The fiber suspension is led in a manner known per se from the inlet header 11 of the headbox 10 through the manifold grooves 12 to a turbulence generator 14 consisting of several flow tubes 17 arranged in a row and overlapping each other. From the turbulence generator 14 the fiber suspension travels to a slice channel 35 and from there onwards over a schematically shown slice lip 34 to a forming wire (not shown in the figure). In addition, in the discharge opening 35 there may be a plurality of fins (not shown) immediately following the turbulence generator 14 . In the turbulence generator 14, the concentration distribution of the fiber suspension is uniform and any floes that may have formed in the fiber suspension are dispersed. Disperses flocs by creating shear and turbulence in the flow. The turbulence is sufficient to keep the fibers sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com