Short rail type electric sectioning structure

An electrical segmented, short-rail technology, used in power lines, transportation and packaging, vehicle components, etc., can solve the problems of high price, large-capacity DC contactors need to be imported, line blocking, etc., to achieve the effect of excellent economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

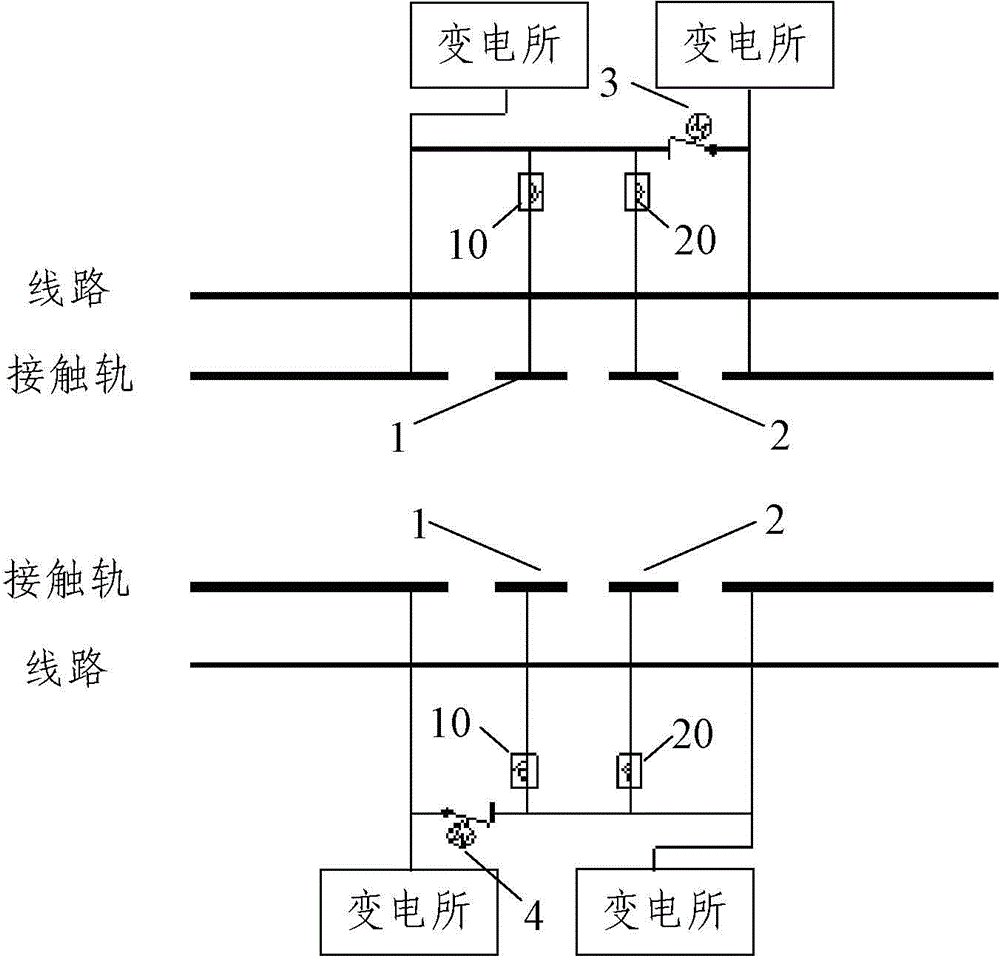

[0015] Such as figure 1 As shown, the short-rail electric segment structure of the present invention includes the first short rail 1 separated from the contact rail on one side in the platform section, the second short rail 2 and the corresponding first short rail separated from the contact rail on the other side. A short rail 1 and a second short rail 2, wherein each first short rail 1 is powered by a first DC contactor 10, and each second short rail 2 is powered by a second DC contactor 20, each side There is no electrical connection between the first short rail 1 and the second short rail 2 on the contact rail, and the parts of the contact rail on each side of the contact rail except the first short rail 1 and the second short rail 2 are respectively connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap