Three-hole carbon brush box apparatus of high-power wind power generator

A technology of wind generators and brush boxes, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as burning equipment, insufficient power, and inability to meet high-power slip ring current transmission, and achieve the effect of avoiding electrical failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

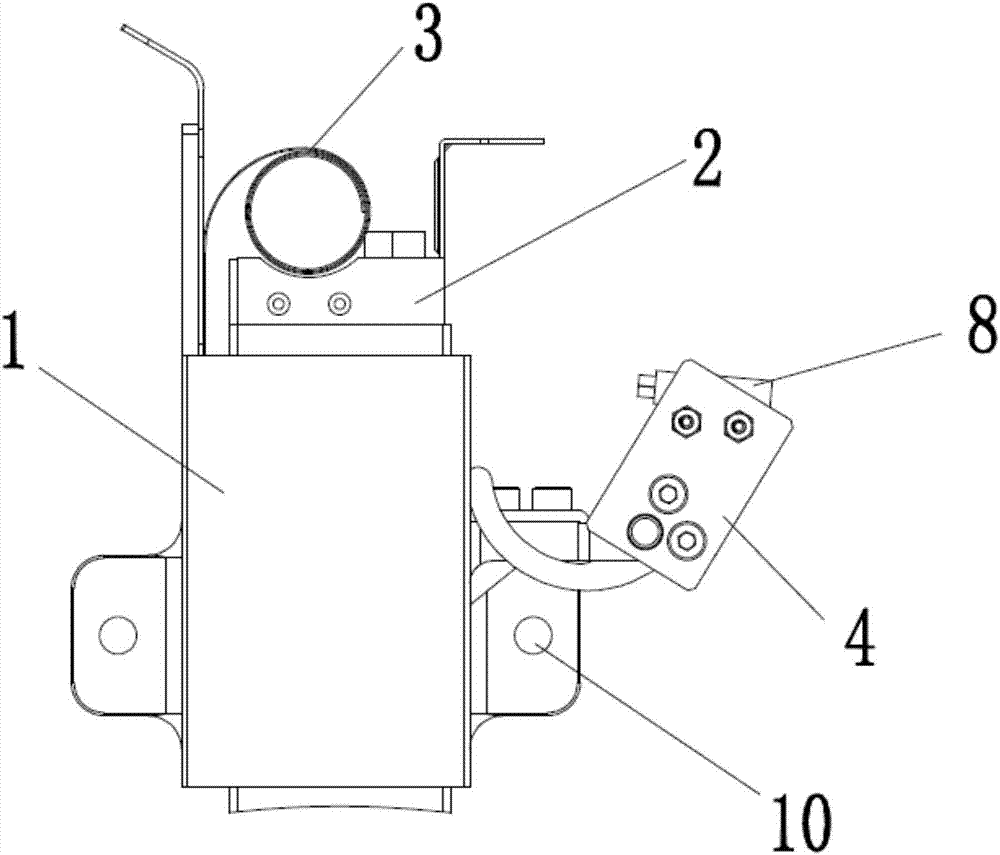

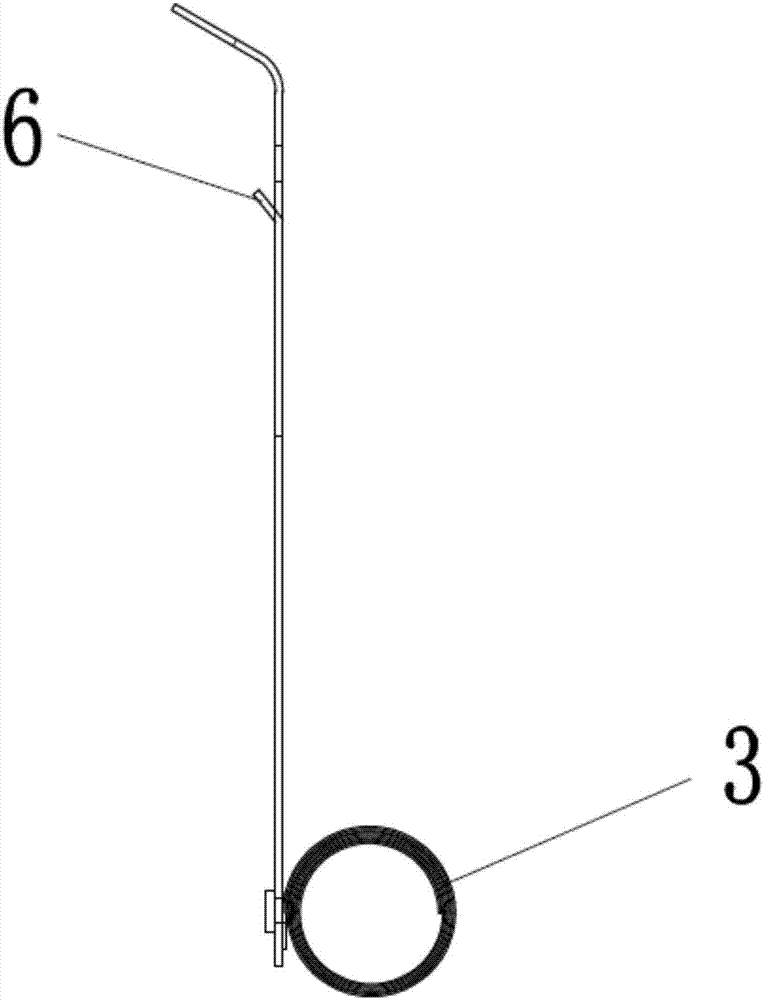

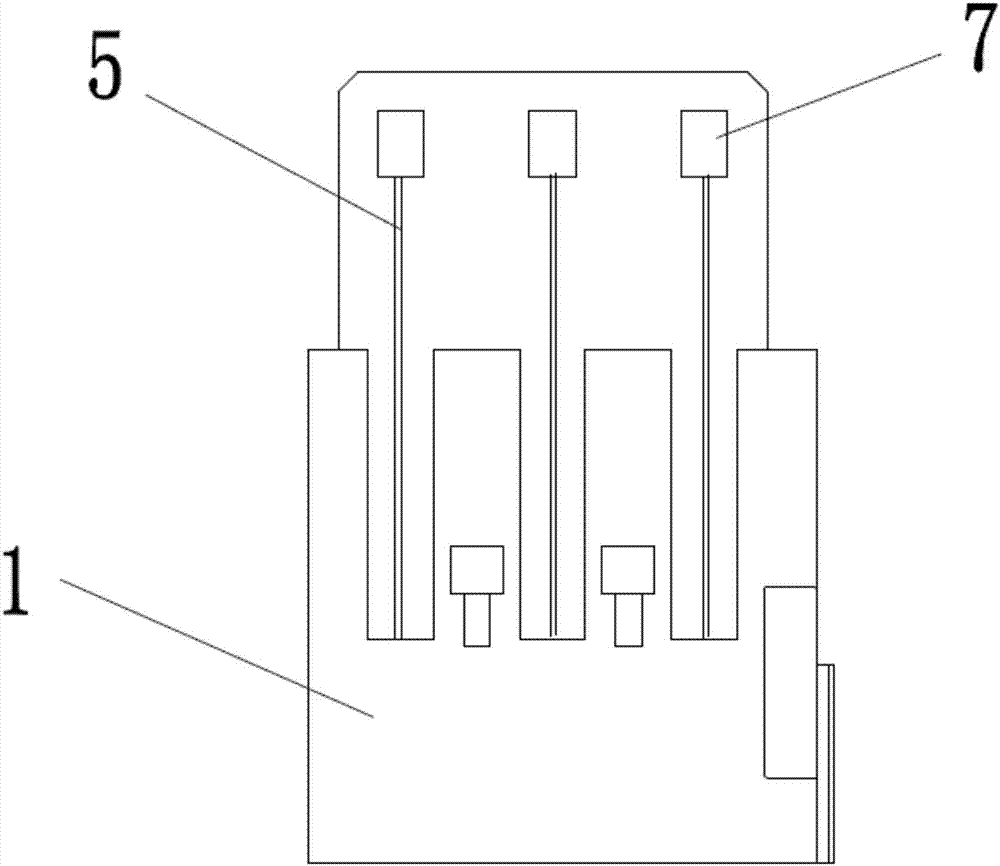

[0013] The embodiments of the three-hole carbon brush box device of the high-power wind generator of the present invention will be further described below with reference to the accompanying drawings.

[0014] A three-hole carbon brush box device for a high-power wind generator, comprising a brush box body, a carbon brush 2, a compression spring 3, and a contact alarm switch 4. The brush box body is an integrated brush box 1, two parts of the integrated brush box 1. Both sides are provided with threaded mounting holes 10, and the integrated brush box 1 is provided with three square openings 9 for installing carbon brushes 2, the compression spring 3 is an integrated constant pressure spring 3, and the contact alarm switch 4 is fixed in the integrated On the brush box 1, a groove 5 is provided on the other side of the integrated brush box 1, and the integral constant pressure spring 3 is pressed in the groove 5. One side of the integrated brush box 1 with the groove 5 is also provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com