Chain wheel chamber casing of engine

A sprocket chamber and engine technology, applied in the direction of engine components, machines/engines, casings, etc., can solve the problems of reduced installation work, inability to completely fix, and inability to prevent oil leakage, and achieve the effect of reducing installation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below through specific examples. It should be understood that the following examples are exemplary only, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be construed as an explanation of the technical solution of the present invention. Program limitations.

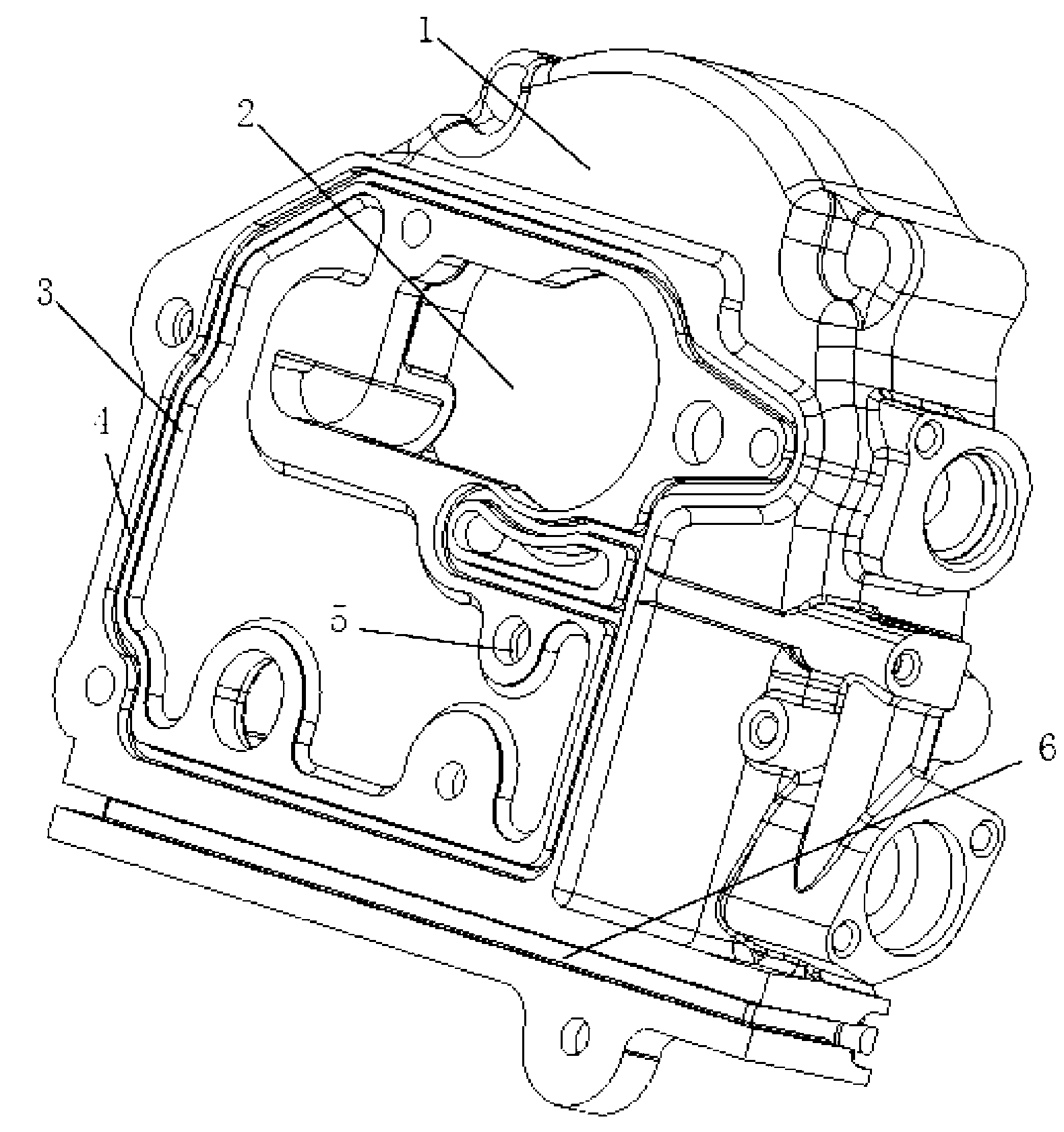

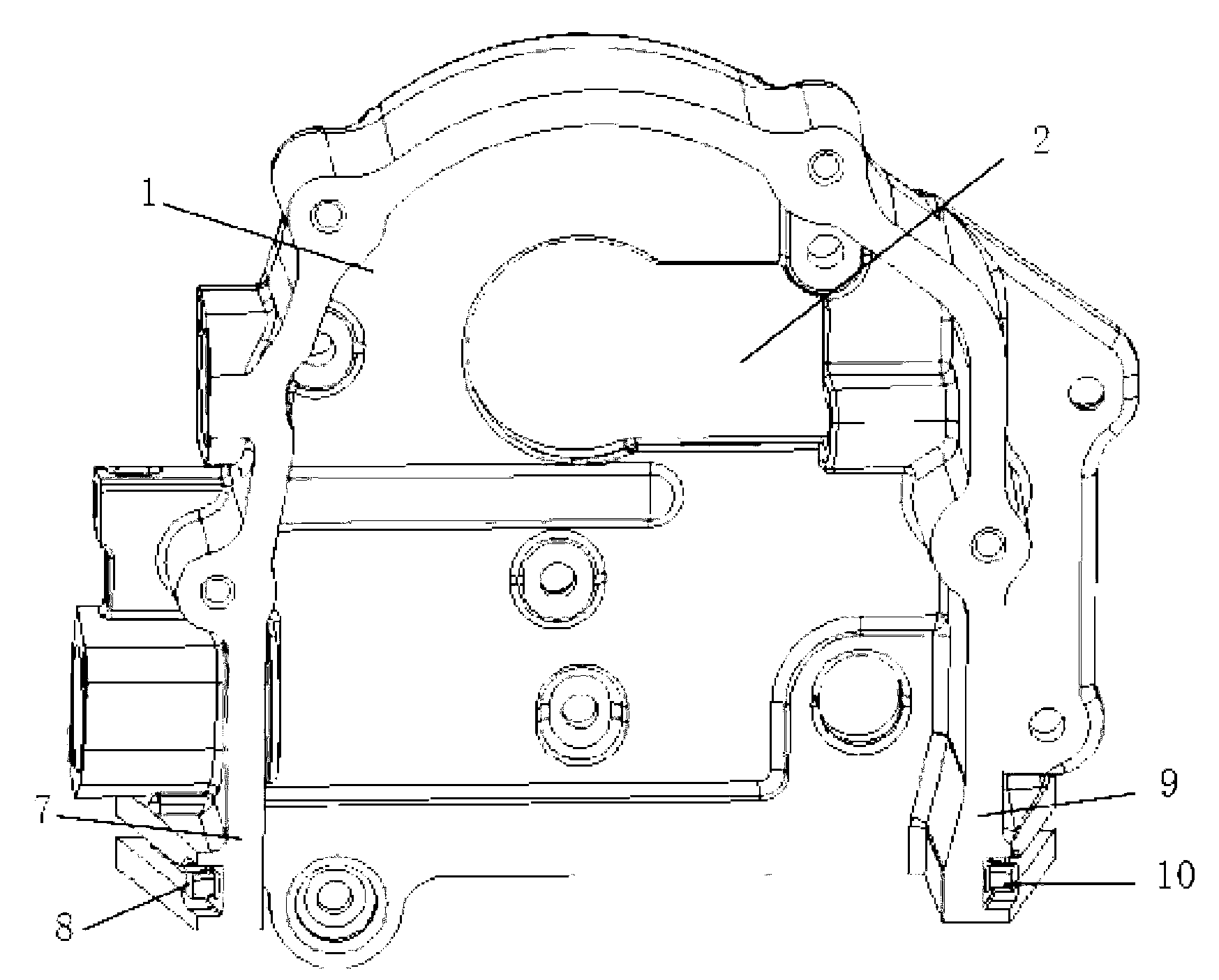

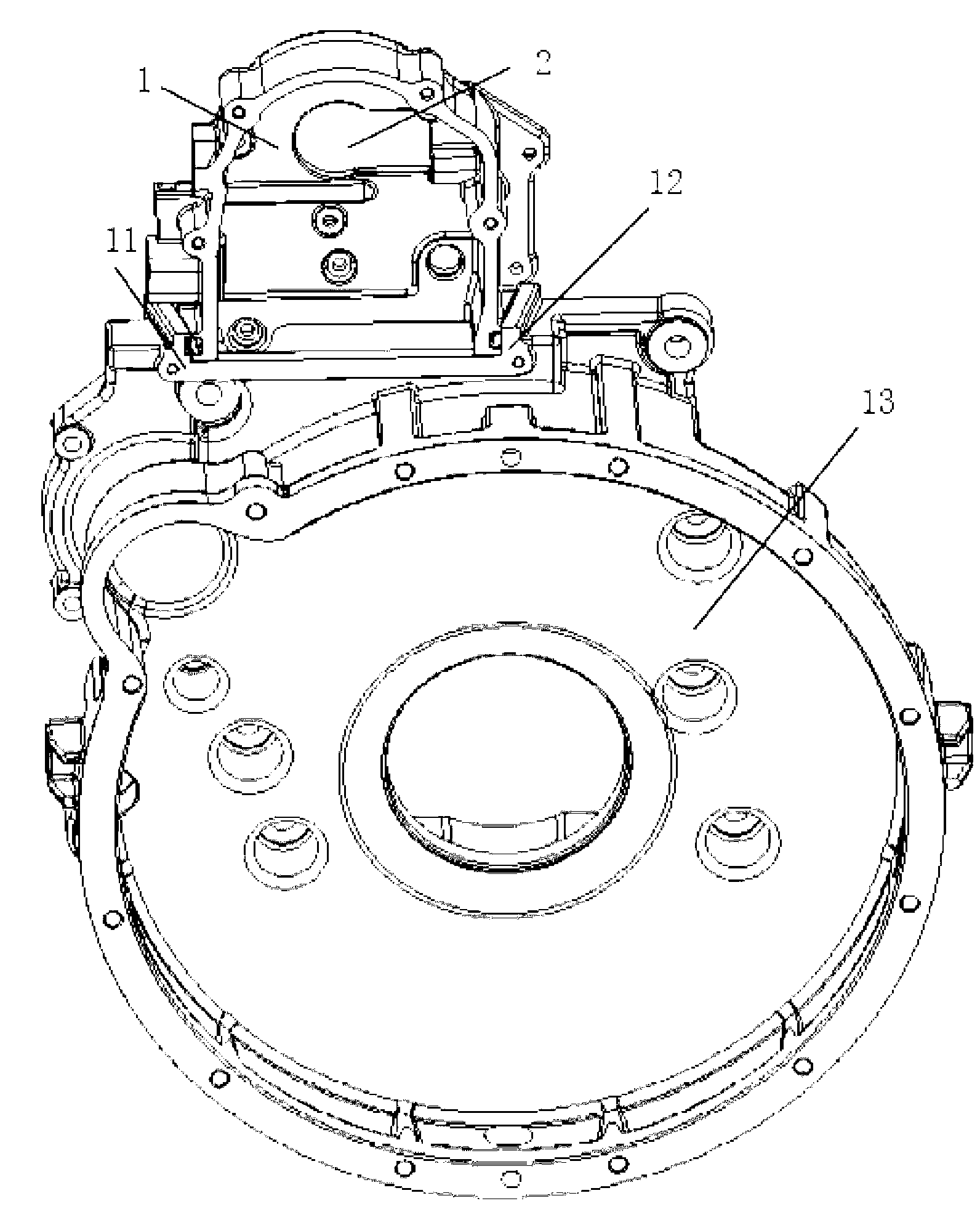

[0027] A kind of engine sprocket housing housing, the sprocket housing is formed with a cavity 1 for accommodating a chain transmission mechanism; a hole 2 passing through a camshaft is formed in the cavity 1, and a hole 2 for passing through a camshaft is formed in the cavity 1 Bolt holes for installing tensioner and other components and mounting holes 5 for fixing with cylinder block and cylinder head.

[0028] The first installation surface 3 on the sprocket housing housing is far away from the concave cavity and faces the engine block and cylinder head, and the second installatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com