Slot-type dual-axial sun tracking heat collecting device

A heat collector, biaxial technology, applied in the field of auxiliary equipment for solar heat collection, can solve the problems of low utilization rate in the horizontal direction, cumbersome tracking control, increase equipment energy consumption, etc., so as to improve the utilization rate of light and heat and reduce tracking Energy consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

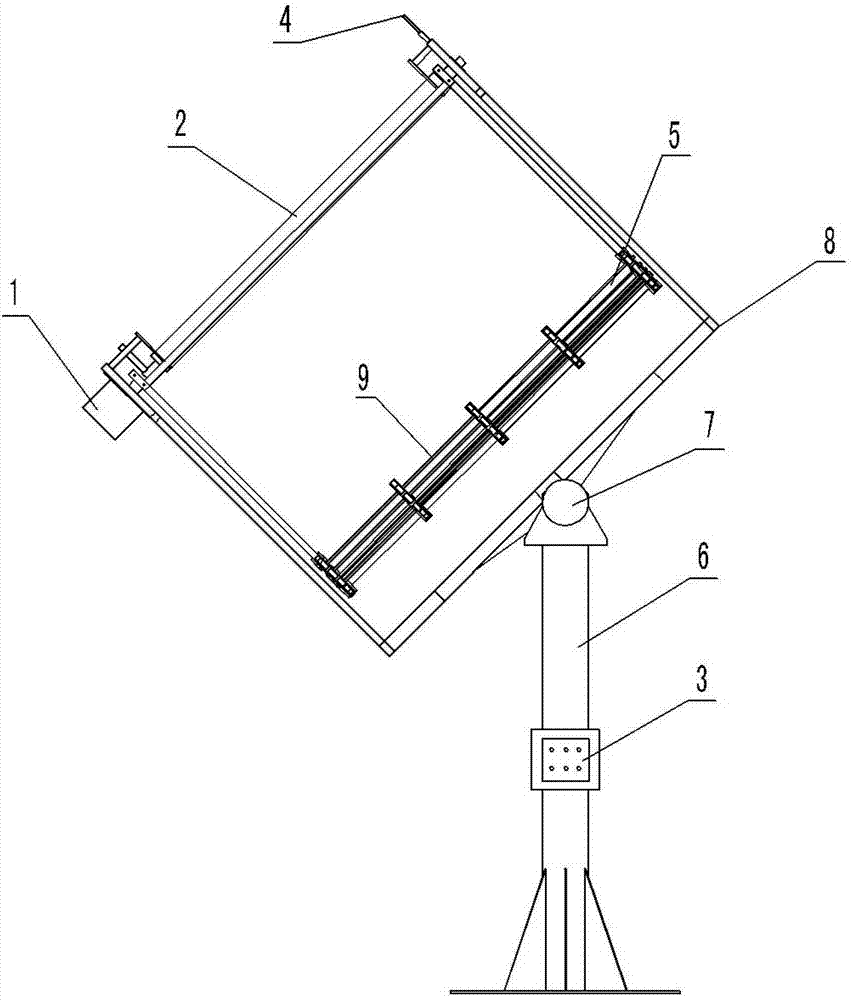

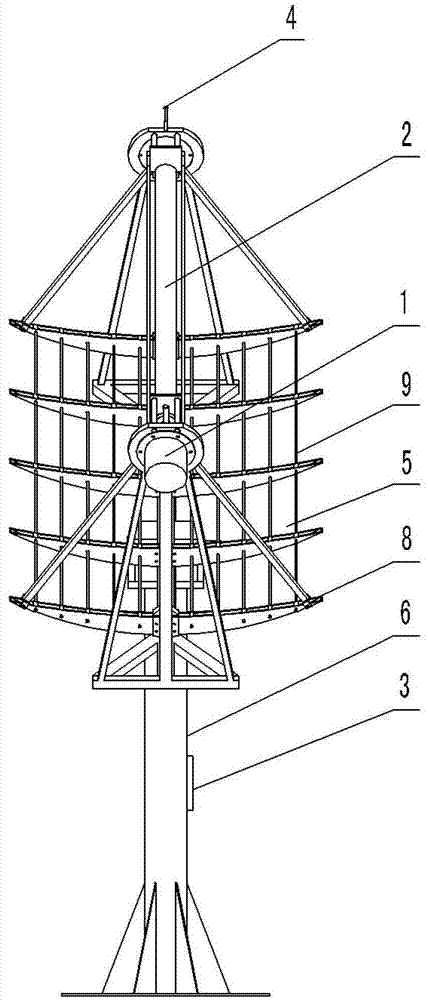

[0016] see figure 1 and figure 2 , the structure of the trough-type biaxial daily tracking heat collector in this embodiment is set as follows: the two tracking power sources are respectively the trough deceleration motor 1 and the tilting deceleration motor 7; the trough deceleration motor 1 and the tilting deceleration motor 7 Drive the rotation of the trough mirror turret 9 and the north-south turret 8 respectively;

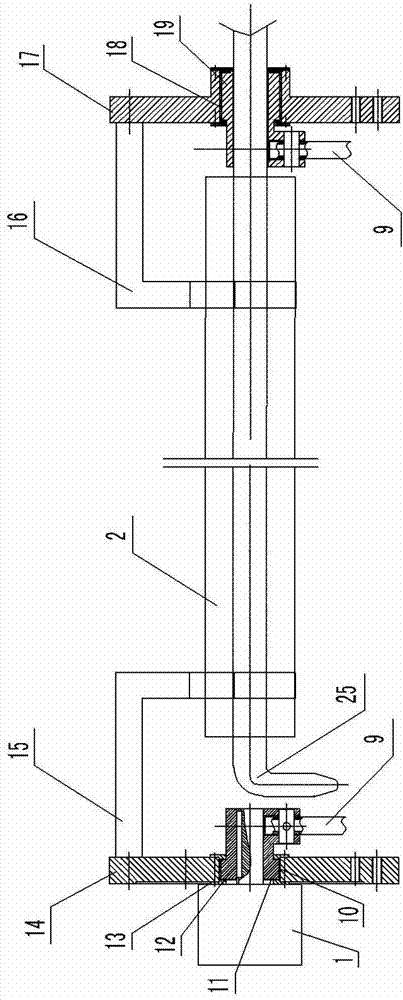

[0017] Such as image 3 As shown, the heat collecting tube 2 is fixed on the left bracket 15 and the right bracket 16, and the heat transfer medium tube 25 is placed in the heat collecting tube 2; the sun azimuth tracker 4 is installed on the upper end of the north-south turret 8; the tracking control cabinet 3 is arranged on the base 6 Above: the sun azimuth tracker 4, the pitch reduction motor 7 and the trough frame reduction motor 1 are connected with the tracking control cabinet 3 by wires.

[0018] Such as Figure 4 As shown, the tilting reduction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com