Composite working tube and solar energy steam-generating equipment

A solar steam generation device technology, applied to solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of large reflected light and heat loss, poor heat preservation effect of the focuser, etc., and achieve high light energy conversion efficiency, focusing and Good heating effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

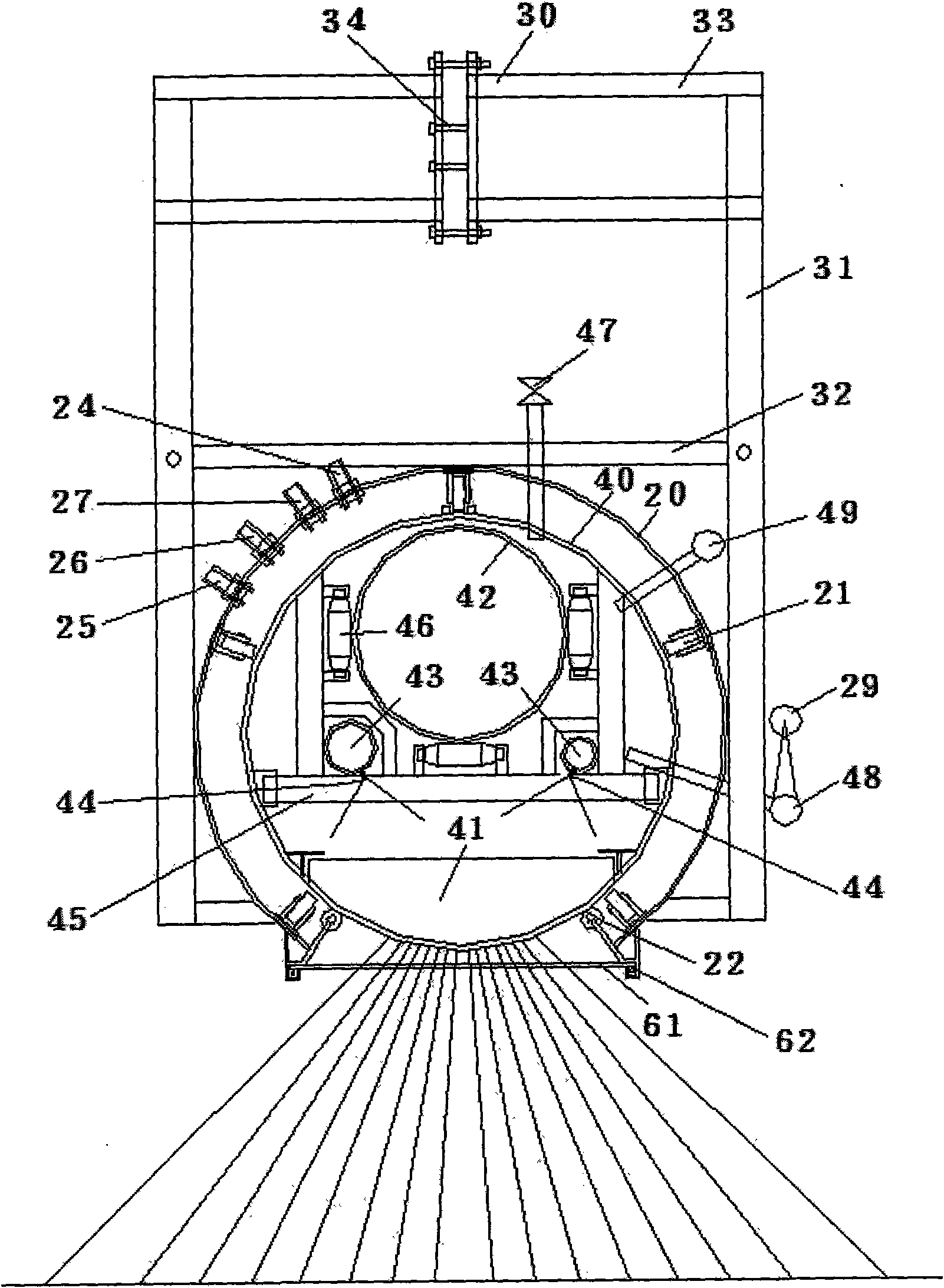

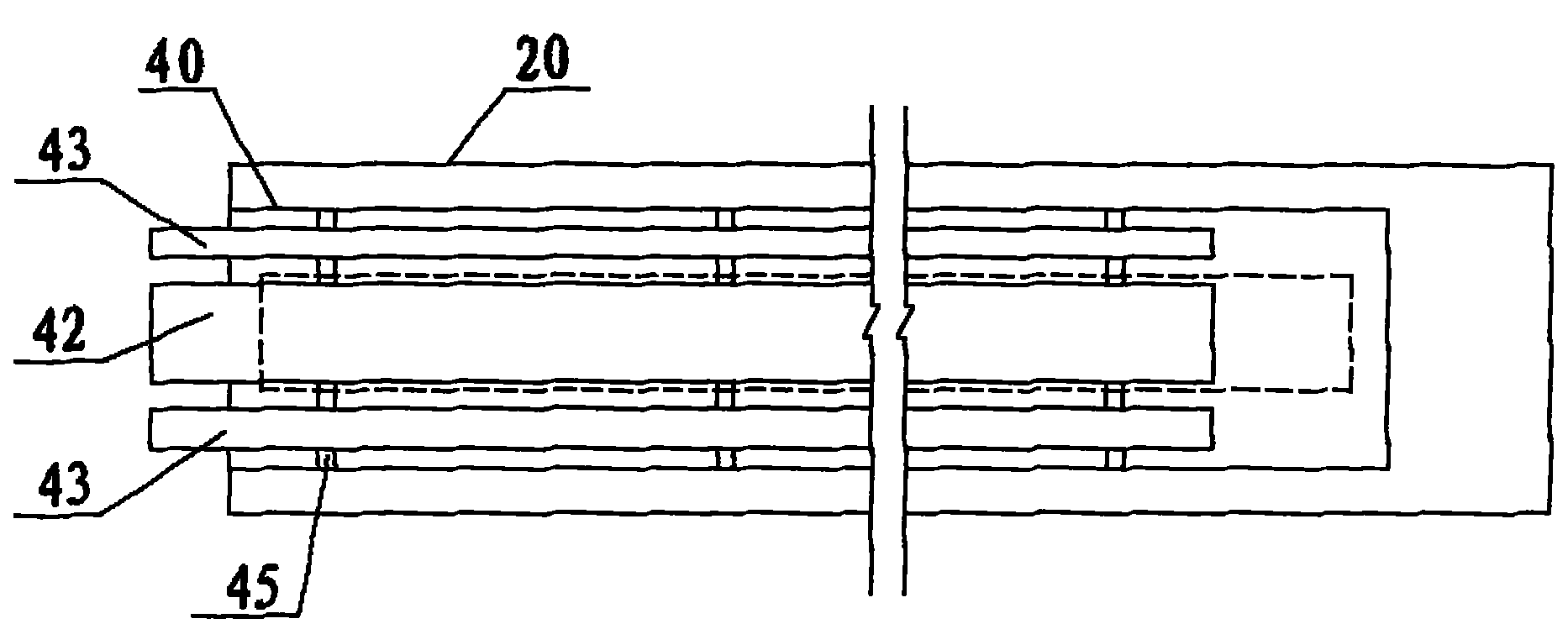

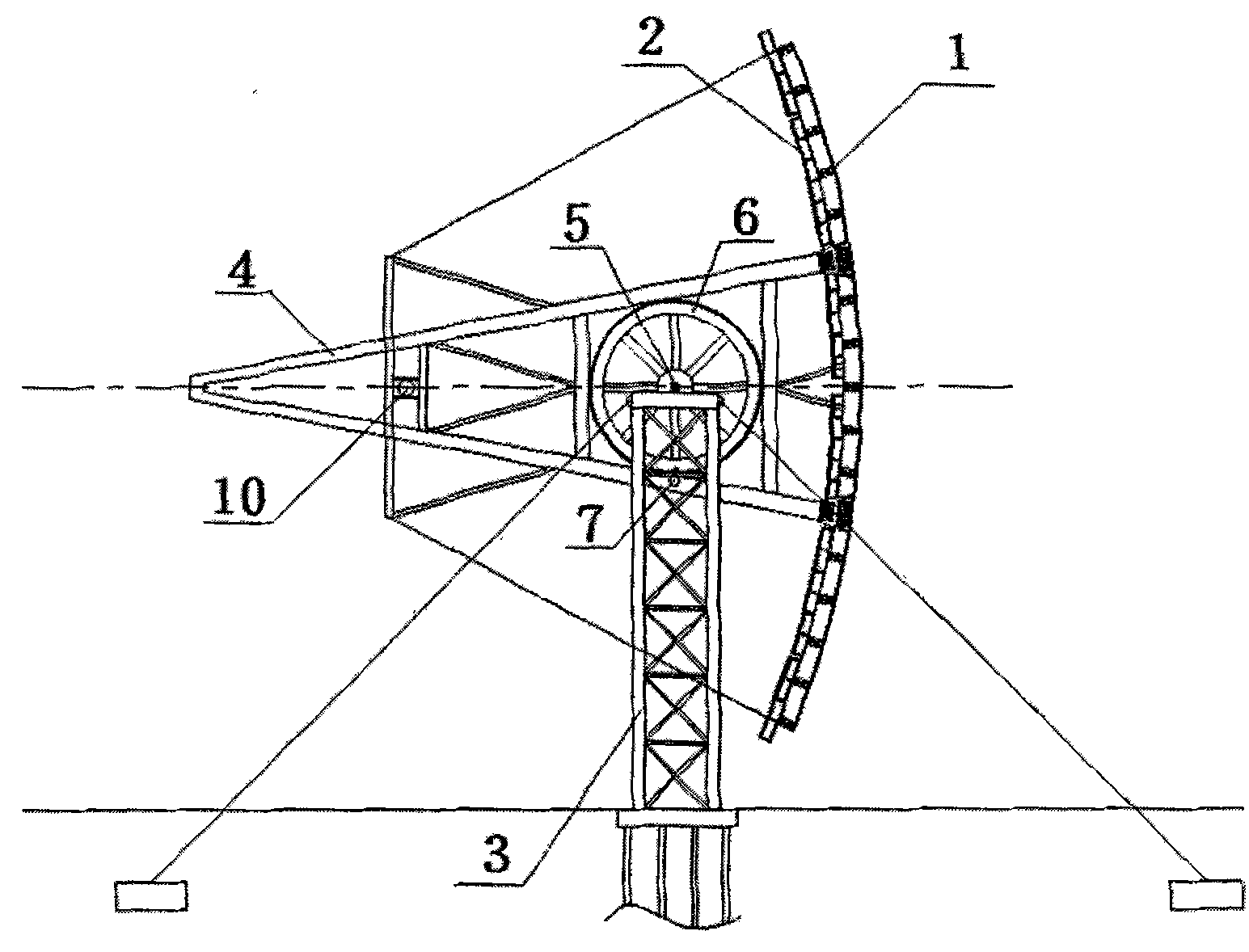

[0039] see figure 1 , figure 2 , a combined work tube of the present invention has a focus tube 40 with both ends closed, and a heat storage material 41 is fixed on the inner wall of the light collecting surface of the focus tube 40, and the heat storage material 41 inside the focus tube 40 is along the tube The longitudinal direction is provided with a steam pipe 42 and a water supply pipe 43, and one end of the steam pipe 42 and the water supply pipe 43 passes through one end of the focusing pipe 40 to the outside, and the other end of the steam pipe 42 is a steam inlet, and the focusing pipe 40 The inner water supply pipe 43 is provided with a water spray port 44 corresponding to the heat storage material 41, and the outer wall of the focusing tube 40 is sealed with a heat insulating tube 20, and the length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com