Approximate model technology based composite foamed plastic interface phase mechanical test method

A technology of syntactic foam and interfacial phase mechanics, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of lack of accurate and reliable interface parameter support in mechanical models, and the deviation between predicted results and actual values, etc., to achieve strong engineering Application prospect, improvement of precision, effect of improving overall precision

Inactive Publication Date: 2015-05-27

SHANGHAI JIAO TONG UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in the study of predicting the macroscopic mechanical properties of syntactic foams, the mechanical model of the interface phase lacks accurate and reliable interface parameter support, which eventually leads to a large deviation between the predicted results and the actual values.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0029] This embodiment includes the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

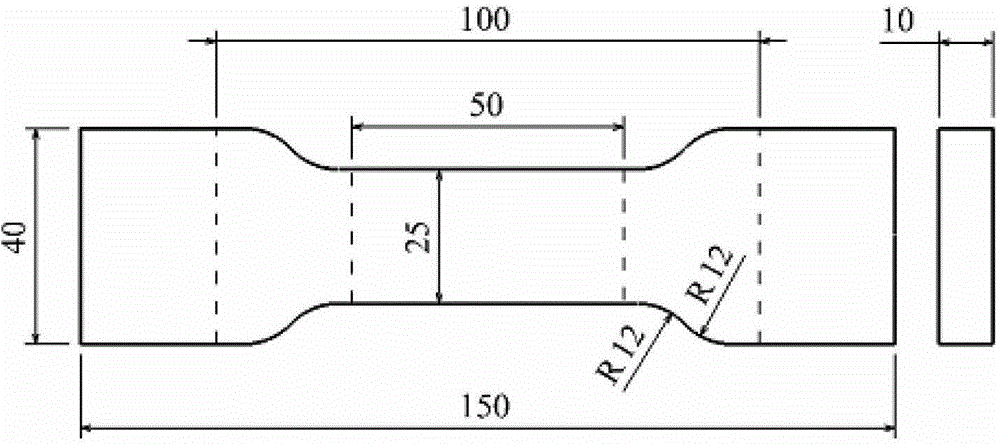

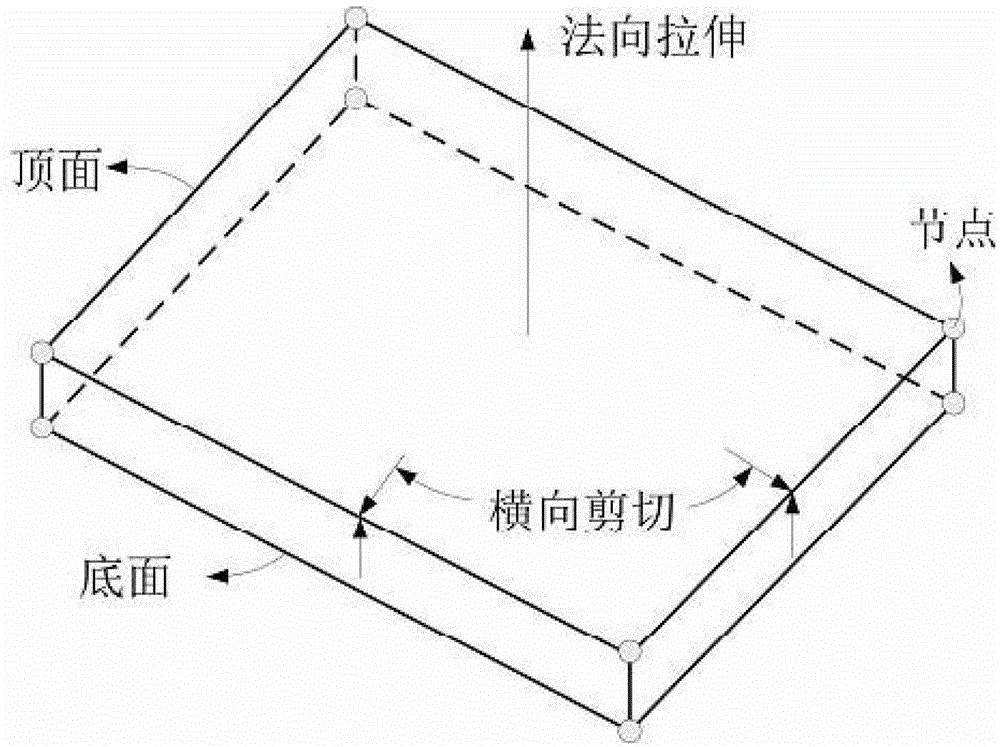

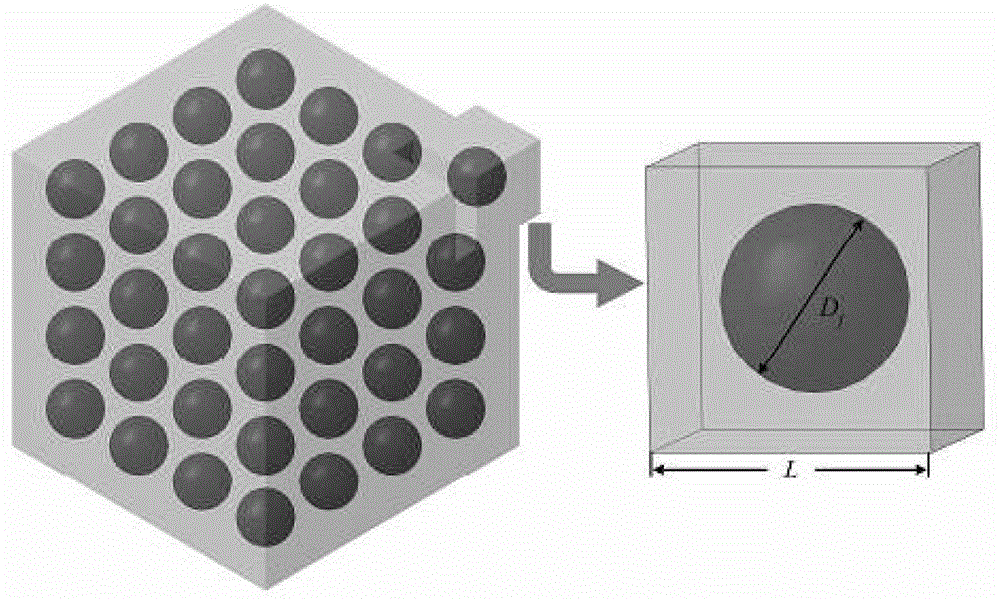

The invention discloses an approximate model technology and calculation mesomechanics based composite foamed plastic interface phase mechanical parameter test method in the composite material field. The direct experiment measurement of the interface phase is avoided against the difficult experiment measurement of the interface properties of a composite foamed plastic which is a composite material filled by hollow spherical particles and the accurate and reliable interface parameter support lack of an interface phase mechanical model in the researches on the macromechanical performances of the composite foamed plastic, and the elastic stiffness constant and the thickness of the interface phase of the composite foamed plastic are identified by utilizing the approximate model technology through the combination of the macromechanical experiments and microscopic finite element simulation. The method disclosed in the invention overcomes an obstacle that the interface performances of materials of the above type cannot be directly obtained, provides accurate and reliable mechanical parameters for the interface phase modeling, and lays a foundation for the accurate prediction of the macromechanical performances of the materials of the type.

Description

technical field [0001] The invention relates to a method for testing mechanical parameters in the field of composite materials, in particular to a method for testing the interface phase mechanics of composite foam plastics based on approximate model technology. Background technique [0002] During the production and preparation of composite materials, due to complex thermal effects, chemical effects, and crystallization effects, an interface will be formed between the matrix and the reinforcing phase, also known as interface phase or interface layer. The interface phase is obviously different from the component materials (matrix, reinforcement phase) both in chemical composition and in mechanical properties. With the rapid development of composite mechanics, it is increasingly recognized that the performance of composite materials is not only closely related to the matrix and reinforcement phase, but also the interface plays a crucial role. The mechanical properties of comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/08

Inventor 朱平喻明王增伟

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com