Integration equipment and detection method for evaluating coating bonding strength based on interface fracture toughness

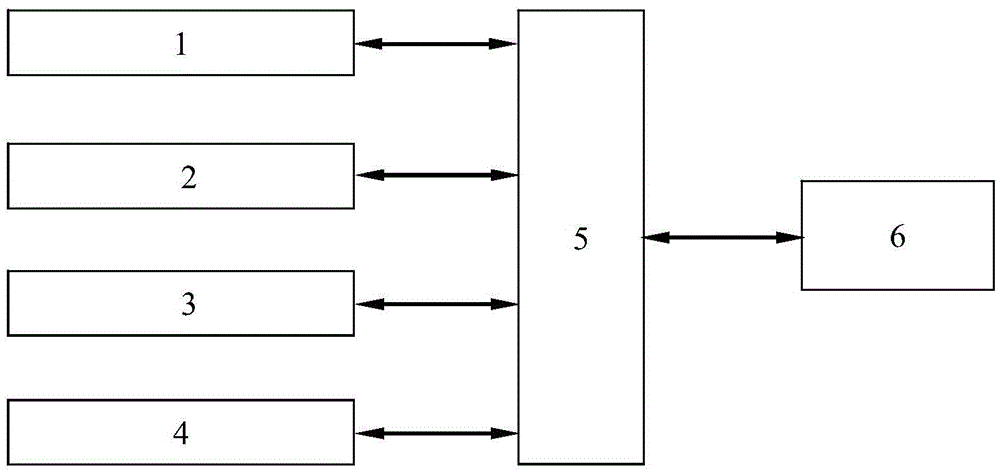

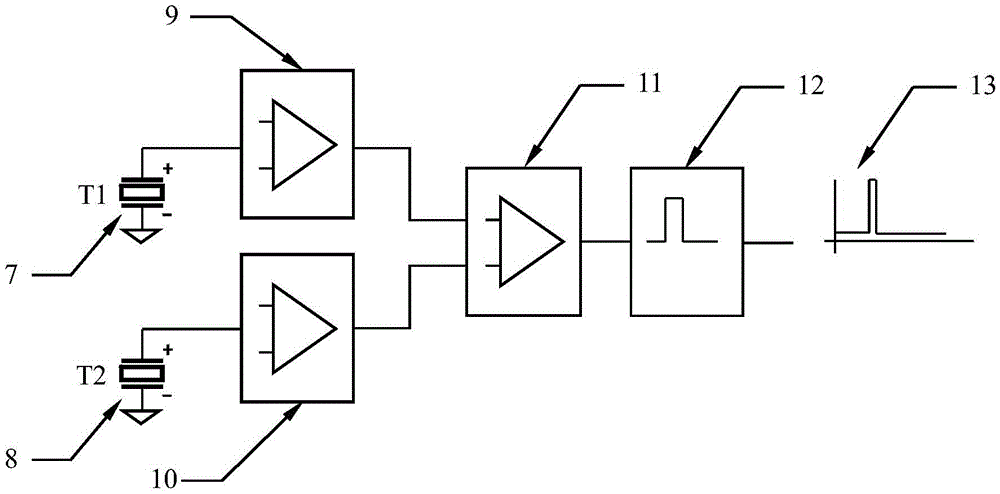

A technology that combines strength and fracture toughness. It is applied in the directions of strength characteristics, testing material strength by applying stable tension/pressure, measuring devices, etc., to achieve the effects of simple preparation, clear equipment and detection principles, and beneficial modular design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

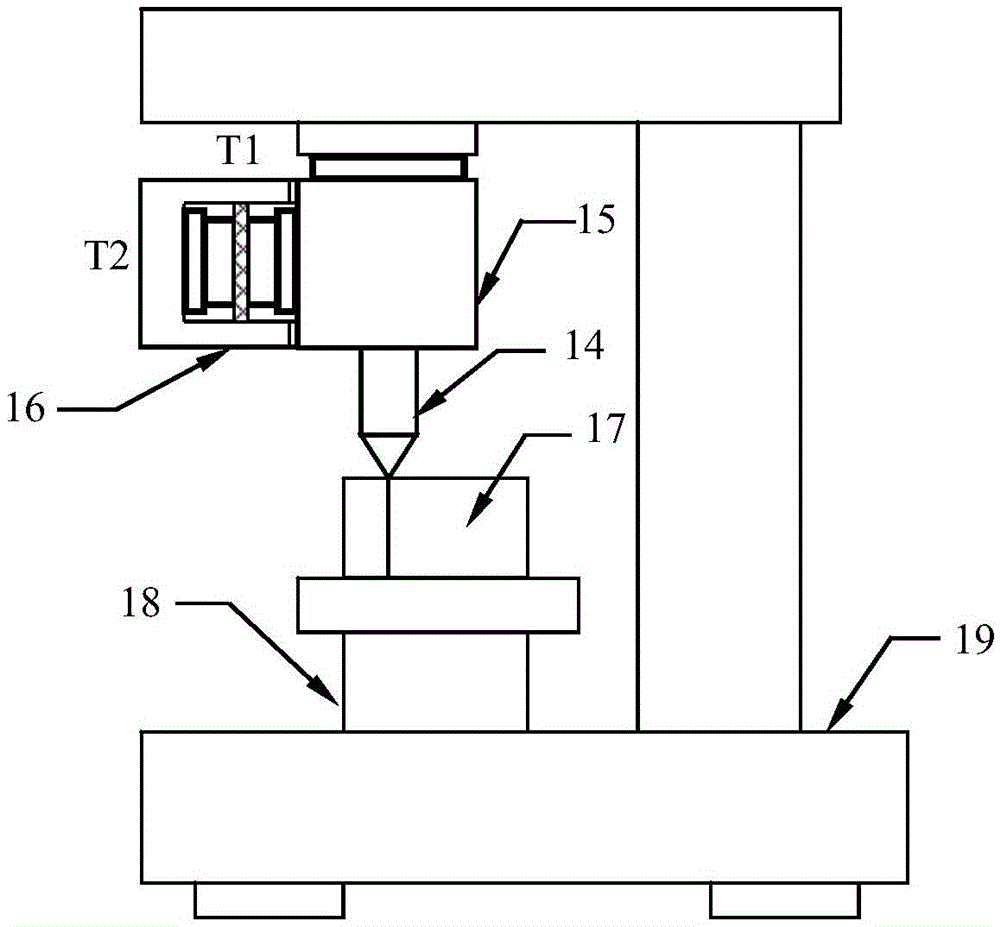

[0032] On the 316L stainless steel sample, HVOF high-speed flame thermal spraying WC-10Ni coating, after stress relief annealing heat treatment, measure the bonding strength. The detection method adopts the following steps:

[0033] 1) Preparation of coating sample and substrate sample: process the coating sample and substrate sample with the same shape and size as a cuboid, the thickness of the sample is 6mm, the length is 30mm, and the width is 15mm. The same long sample is cut off on the line, the thickness of the coating is 350 μm, the upper and lower surfaces of the sample are parallel and mechanically polished, the surface roughness is Ra=0.05 μm; the longitudinal cross-section of the coated sample is polished to a mirror surface for Metallographic measurement of coating thickness, porosity, microhardness measurement of coating and substrate, and indentation test of coating-substrate interface;

[0034] 2) Ultrasonic non-destructive measurement of the elastic modulus of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com