Mineshaft multiphase flow device for simulating deep-water oil and gas production

A multi-phase flow, oil and gas extraction technology, applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of narrow experimental parameters, less equipment research and development, affecting the normal operation of drilling and production systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

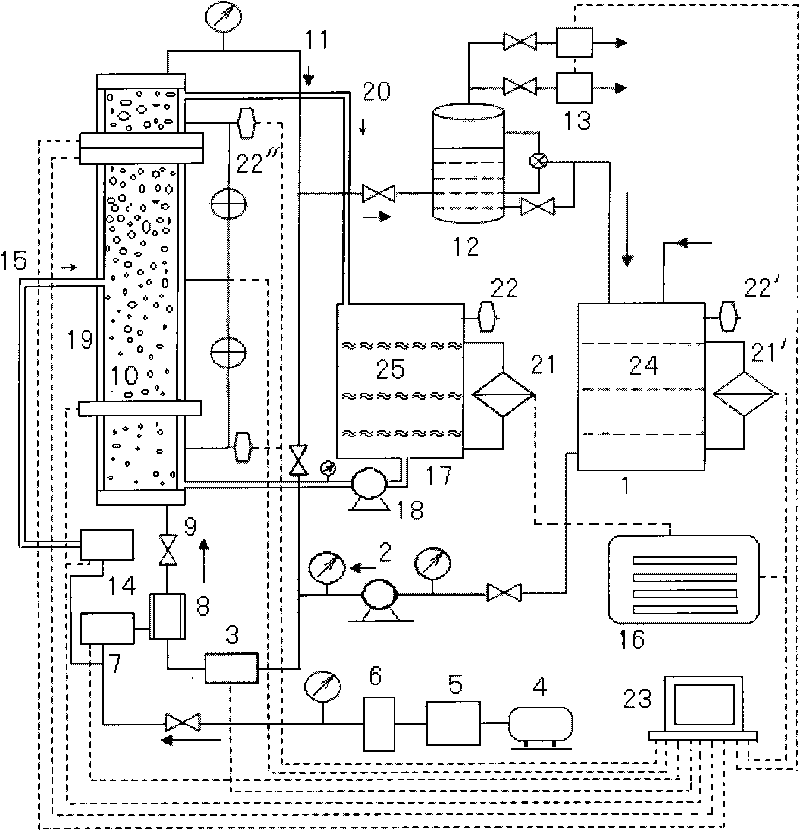

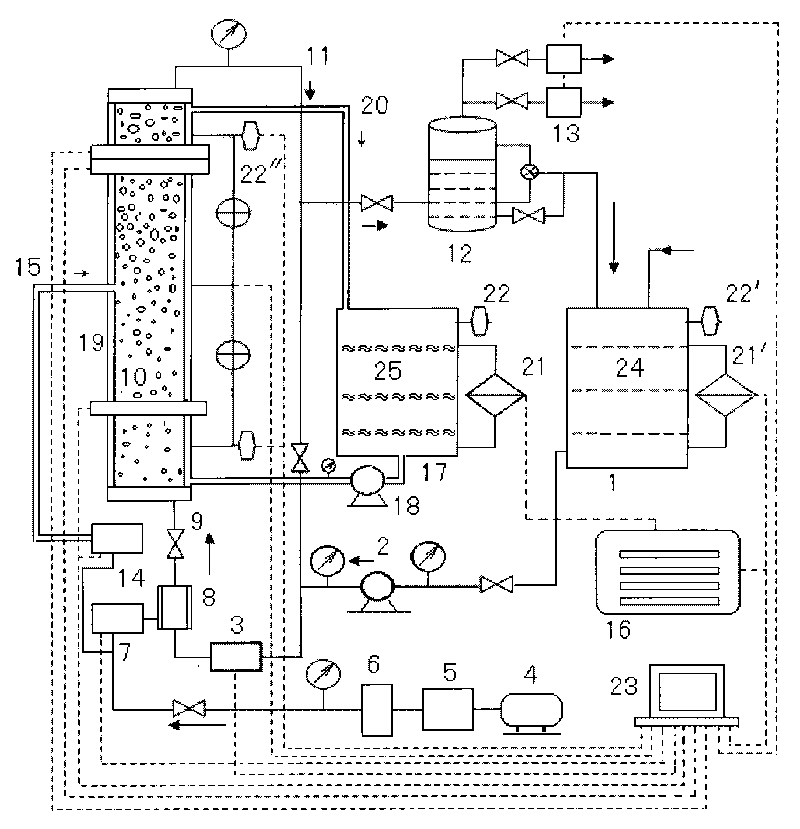

[0012] Embodiment 1: in combination with figure 1 , the present invention is further described in detail (wellbore fluid flow heat conduction simulation under deep water conditions):

[0013] The condition of simulating the ocean low temperature environment is completed by the ambient temperature maintaining flow system, and the high pressure flow environment is completed by the back pressure control system 13 of the main wellbore; the liquid part of the high pressure flow environment is mainly composed of the water tank 1, the high pressure water pump 2, and the flow fluid temperature control system It is connected with the flow meter 3. The gas part is mainly composed of a gas compressor 4, a high-pressure gas tank 5, a dryer 6 and a gas flow meter 7. The gas-liquid mixing is completed through the bubble generator 8, and then flows through the control valve 9 into the main The wellbore 10; simulated natural gas hydrate decomposition injection gas enters the main wellbore 10 ...

Embodiment 2

[0020] Embodiment 2: The present invention is applied to the heat conduction simulation of gas-liquid flow in the wellbore under deep water conditions, and is used to study the heat conduction law of the wellbore under the condition of gas production during deepwater drilling.

[0021] The technical solution is: the above other structures remain unchanged, and the simulated natural gas hydrate decomposition injection gas passes through the control system 14 and the gas injection pipeline 15 without any work. The high-pressure gas enters the gas-liquid two-phase mixer 8 from the compressor 4, the high-pressure gas tank 5, the dryer 6, and the gas flow controller 7, and the high-pressure water flows from the water tank 1, the high-pressure water pump 2, and the flow controller 3, passing through the air bubbles to generate The device 8 mixes with the gas, enters the high-pressure wellbore 10, the return pipeline 11, the gas-liquid separation tank 12, and the back pressure control...

Embodiment 3

[0022] Embodiment 3: in combination with figure 1 , the present invention is further described in detail (the simulation of the influence of natural gas hydrate phase change on the change of multiphase flow law):

[0023] Same as embodiment 2, it can be realized only by simulating the decomposition of natural gas hydrate and injecting gas to pass through the control system 14 and the gas injection pipeline 15 to start working at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com