System for magnetorheological finishing of substrates

一种磁流变抛光、磁流变流体的技术,应用在磨蚀性抛光和磨光的系统领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

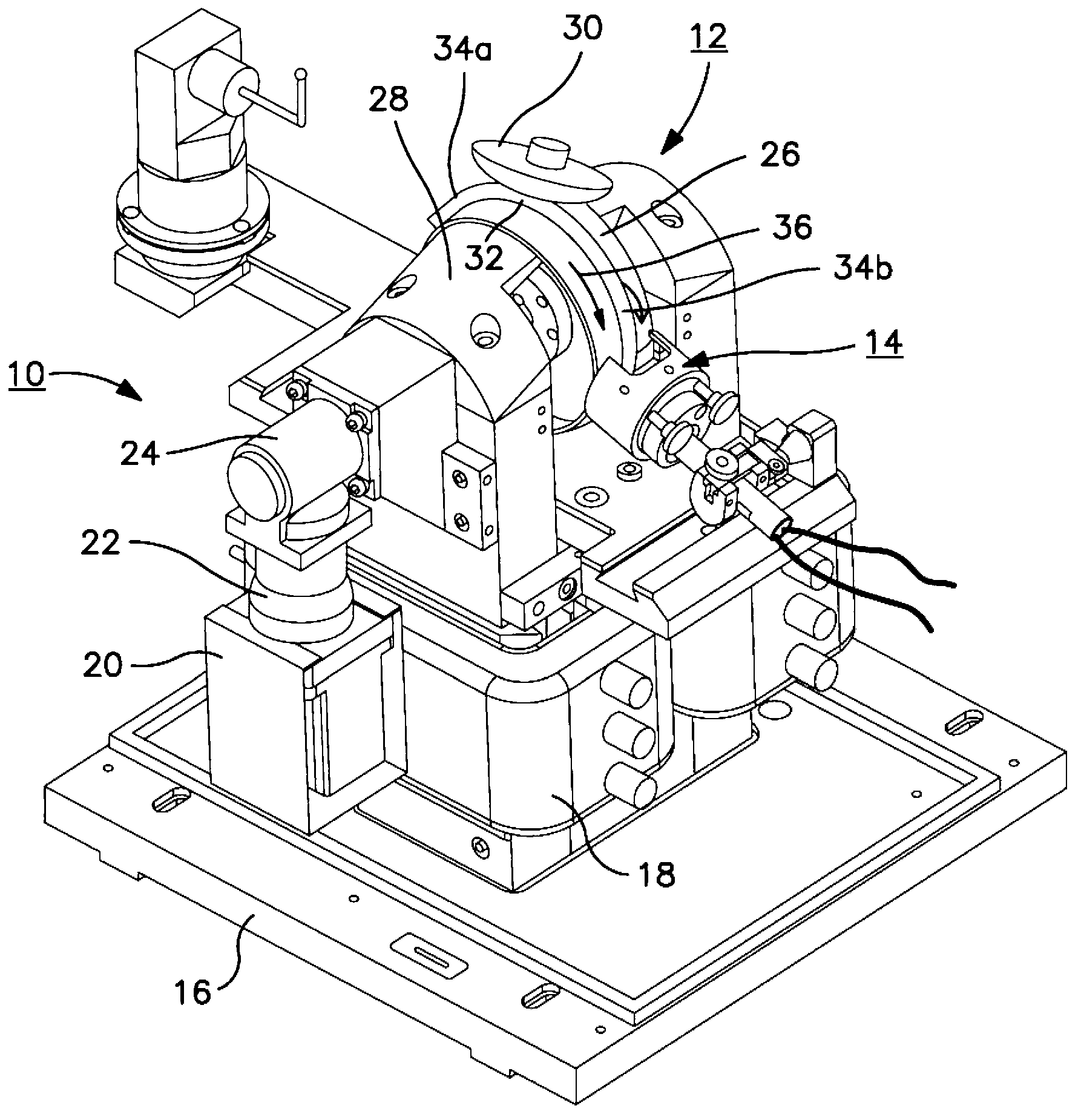

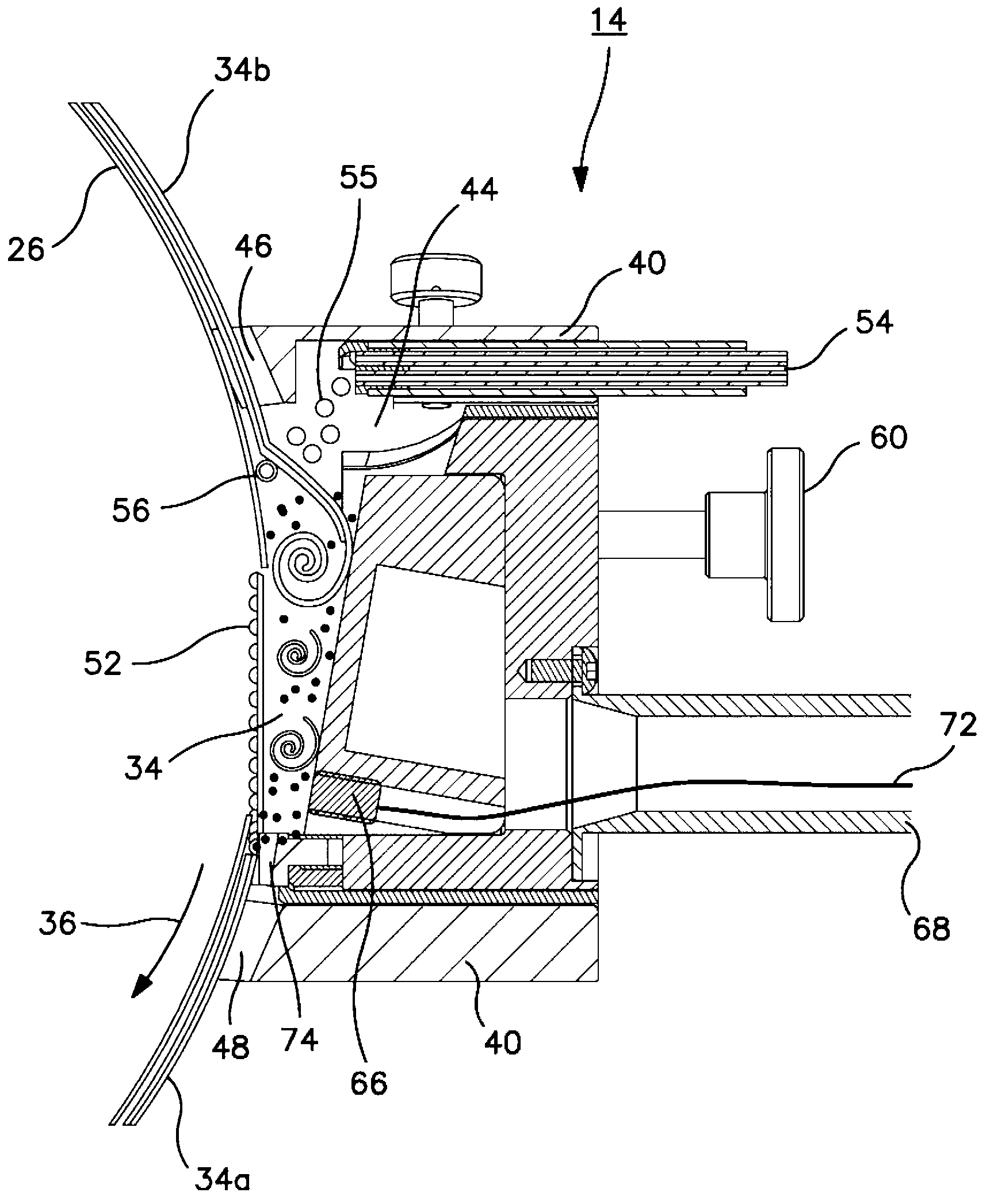

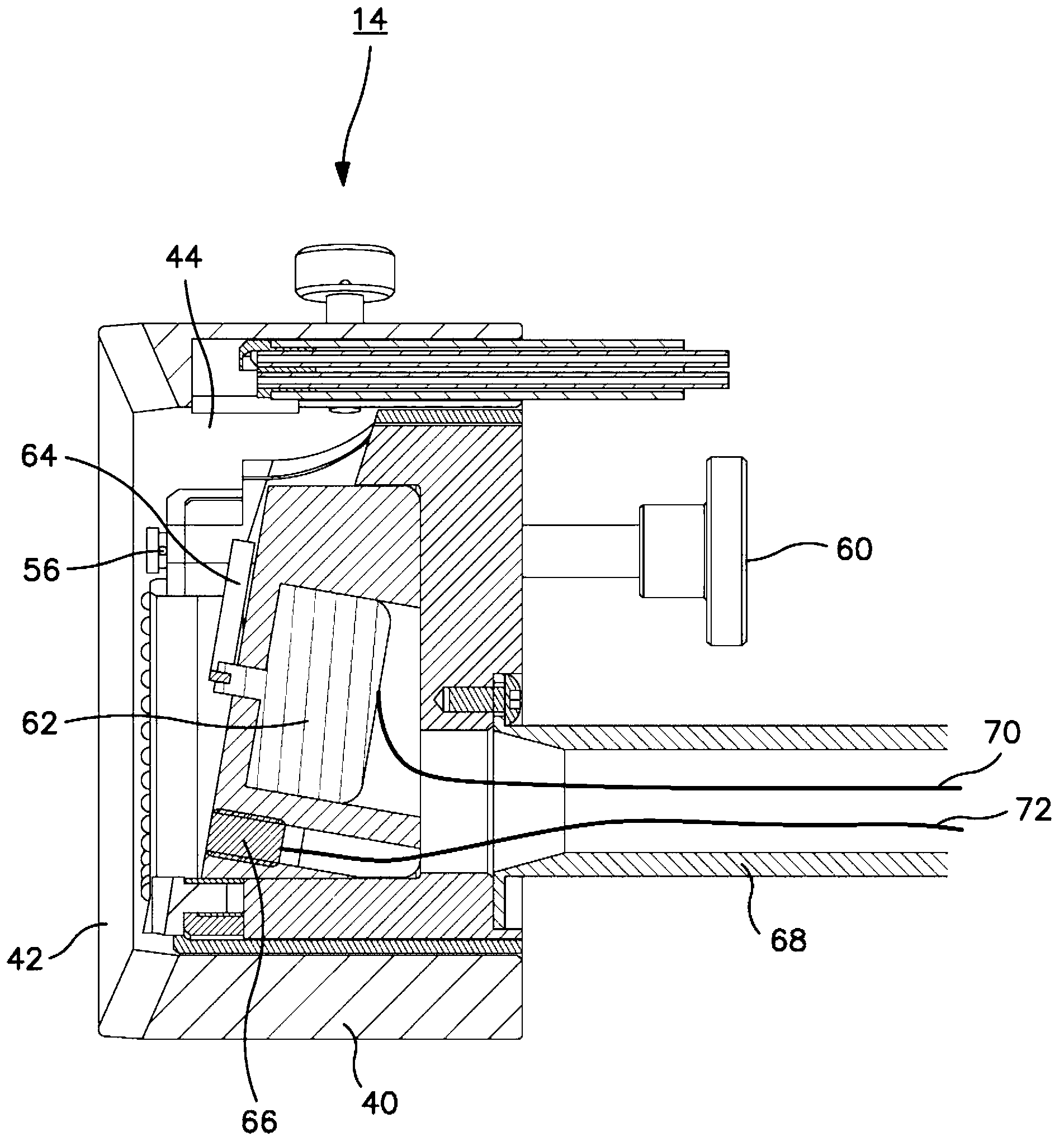

[0034] Reference attached figure 1 , Shows an improved system 10 for magnetorheological polishing of substrates. The system 10 includes a basic polishing device 12 consistent with the prior art, and a new IFMM 14 that exemplifies the present invention.

[0035] The prior art polishing device 12 may include, for example, a platform 16, a base 18, a motor 20, a wheel drive unit 22, a wheel shaft 24, a bearing wheel 26 mounted on the shaft 24, and an electromagnet 28. The substrate or workpiece 30 is mounted above the surface of the wheel 26, preferably at the top-center dead center position, and the substrate or workpiece 30 is separated from the wheel 26, thereby forming a convergent processing zone 32, as the wheel 26 is moved by the motor 20 Rotating in the clockwise direction 36, the low-viscosity MR ribbon 34 a is continuously loaded into the processing area 32 by the wheel 26. In the processing area 32, the magnetic field generated by the electromagnet 28 magneto-rheological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com