Three-dimensional (3D) crystal inside-carven photo frame

A crystal and photo frame technology, which is applied in the field of 3D crystal engraved photo frames, can solve problems such as easy to fall, not clear enough pattern display, no self-contained light source, etc., to achieve the effect of not easy to fall, easy to install, and clear display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

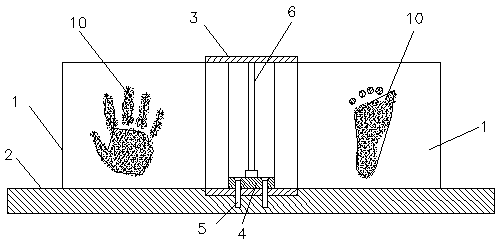

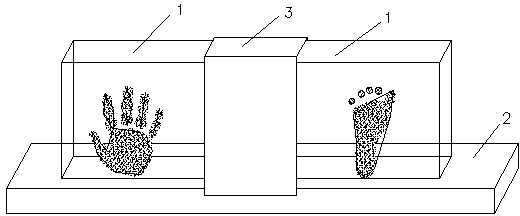

[0024] Such as figure 1 , 2 As shown, the 3D crystal inner-carved photo frame described in this embodiment includes two crystal glass blocks 1 with three-dimensional laser engraved patterns 10 inside, and is characterized in that it also includes a base 2 and a fixed frame with open ends. 3. The bottom of the fixed frame 3 is embedded in the center of the base 2, a limit block 4 is provided on the bottom surface of the fixed frame 3, and the limit block 4 and the bottom surface of the fixed frame 3 are connected to the base by countersunk screws 5 2; the two crystal glass blocks 1 are respectively located on both sides of the fixed frame 3 and the ends are all located in the fixed frame 3; a light source 6 is arranged on the limiting block 4, and the light source 6 is a light tube . The fixed frame 3 is a metal frame, and the base 2 is a metal base 2; obviously, the light source 6 can also be other lighting components, the fixed frame 3 can also be a wooden frame, and the ba...

Embodiment 2

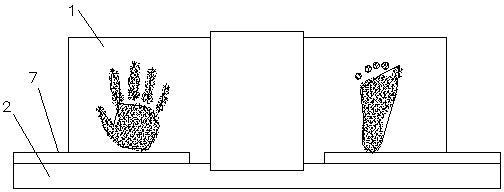

[0027] Such as image 3 As shown, the 3D crystal carved photo frame described in this embodiment is different from Embodiment 1 in that: the base 2 is provided with a limiting plate 7 for limiting the crystal glass block 1; in this way, the crystal glass block 1 is placed on When the base 2 is on the further limit position can be obtained, so that the placement is more stable.

Embodiment 3

[0029] Such as Figure 4 As shown, the 3D crystal engraved photo frame described in this embodiment is different from Embodiment 1 in that: the positions on both sides of the light source 6 on the limiting block 4 are provided with prisms 8; the prisms 8 can make the light emitted by the light source 6 More dispersed, so that the three-dimensional imaging is clearer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com