Horizontal pipe type falling film evaporator

A falling film evaporator, tube type technology, applied in the field of horizontal tube falling film evaporator, can solve the problems of high requirements, blockage of heating tube, inconvenient transportation, etc., to ensure stability, slow down the fluctuation of air flow, and maintain stable supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with embodiments.

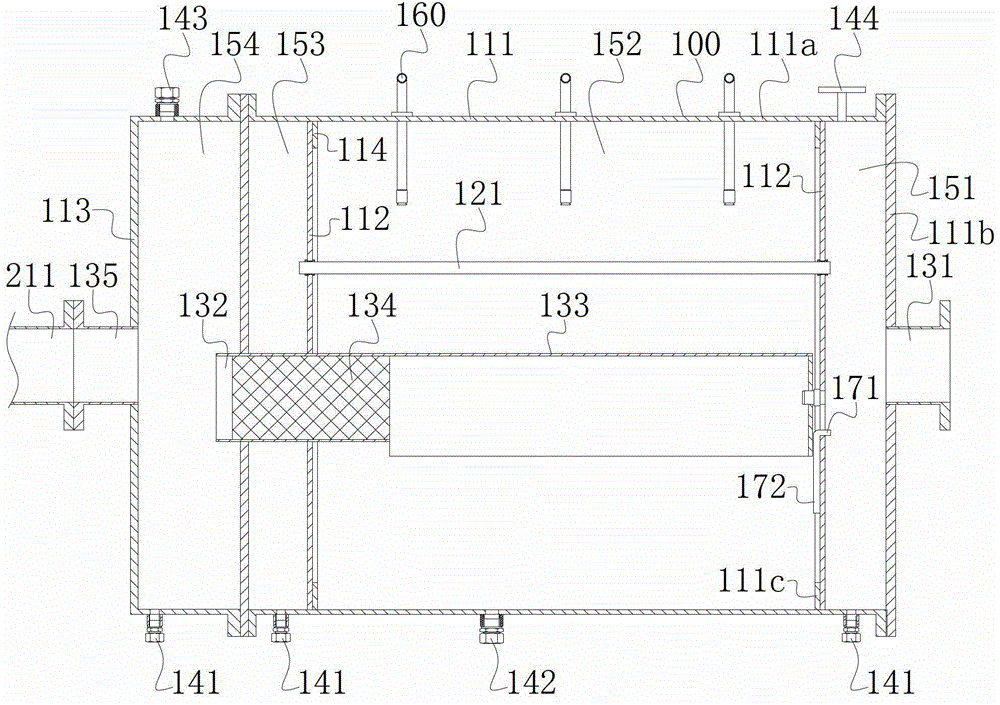

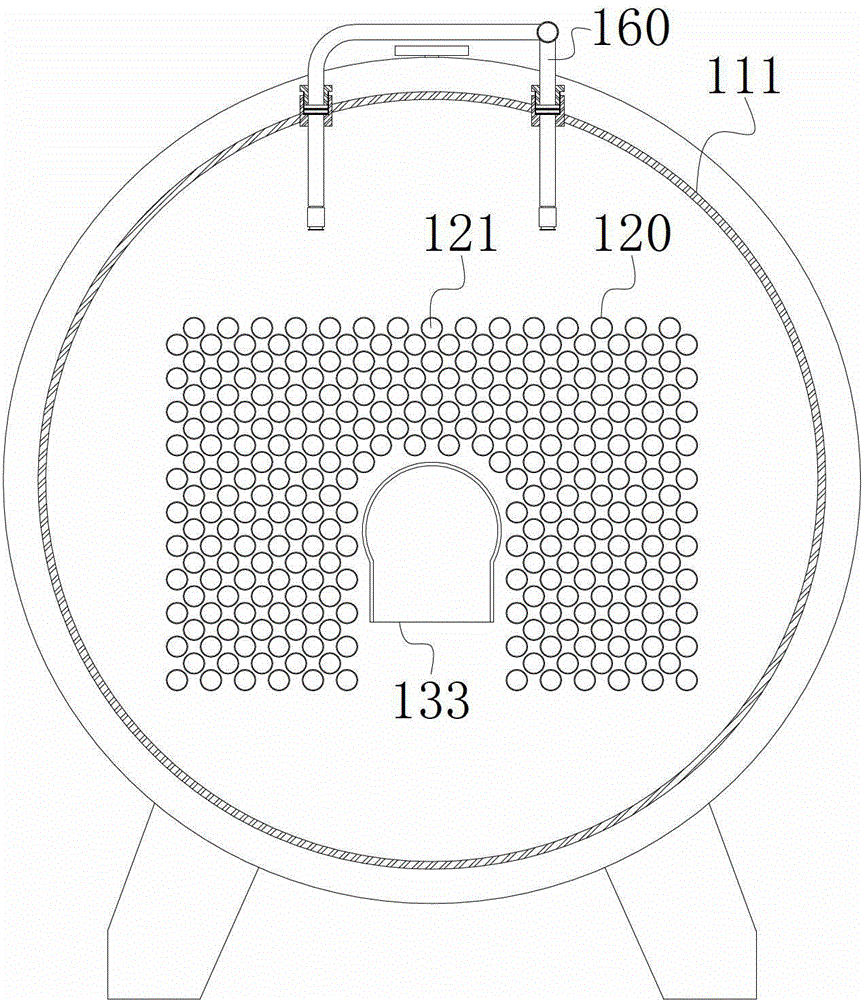

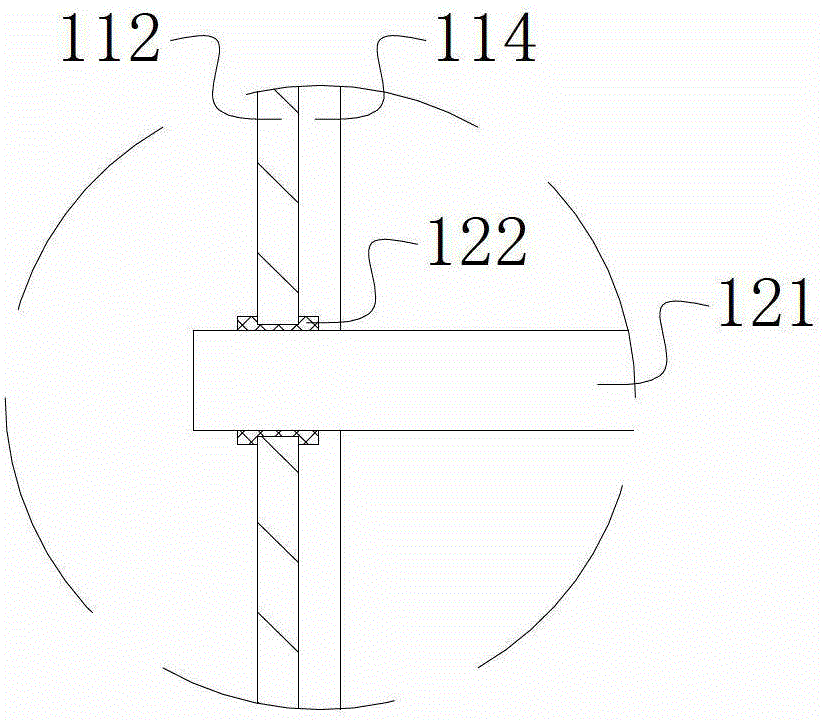

[0021]The horizontal tube falling film evaporator of the present invention comprises a shell 111, two tube sheets 112, a condensation tube bundle 120 and a film distribution device 160; the inner chamber is formed by surrounding the shell 111, and the tube sheets 112 are fixed on the shell 111 inner chamber, along the axial direction of the housing 111, the inner chamber of the housing 111 is divided into a distribution chamber 151, a recovery chamber 153 and an evaporation chamber 152 between the distribution chamber 151 and the recovery chamber 153 by two tube sheets 112; The condensing tube bundle 120 is horizontally arranged in the evaporation chamber 152 along the axial direction of the shell 111, and the two ends of the condensing tube bundle 120 are respectively fixed by the corresponding tube plates 112, and the distribution chamber 151 on both sides of the evaporating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com