Visual operation system of horizontal welding position welding and operation method of operation system

An operating system, horizontal welding technology, used in welding equipment, arc welding equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] see Figure 1 to Figure 13 As shown, the present invention adopts electromagnetic position tracker to detect the angle and spatial coordinates of welding rod; adopt double-layer grid method and multi-layer grid method to set up the horizontal weld pool and the I-shaped groove and V-shaped groove respectively The geometric model of the weld; the double ellipsoid model is used for gravity correction to establish the sink function of the molten pool; the Gaussian heat source model is used for gravity correction to establish the mathematical model of the horizontal weld seam growth.

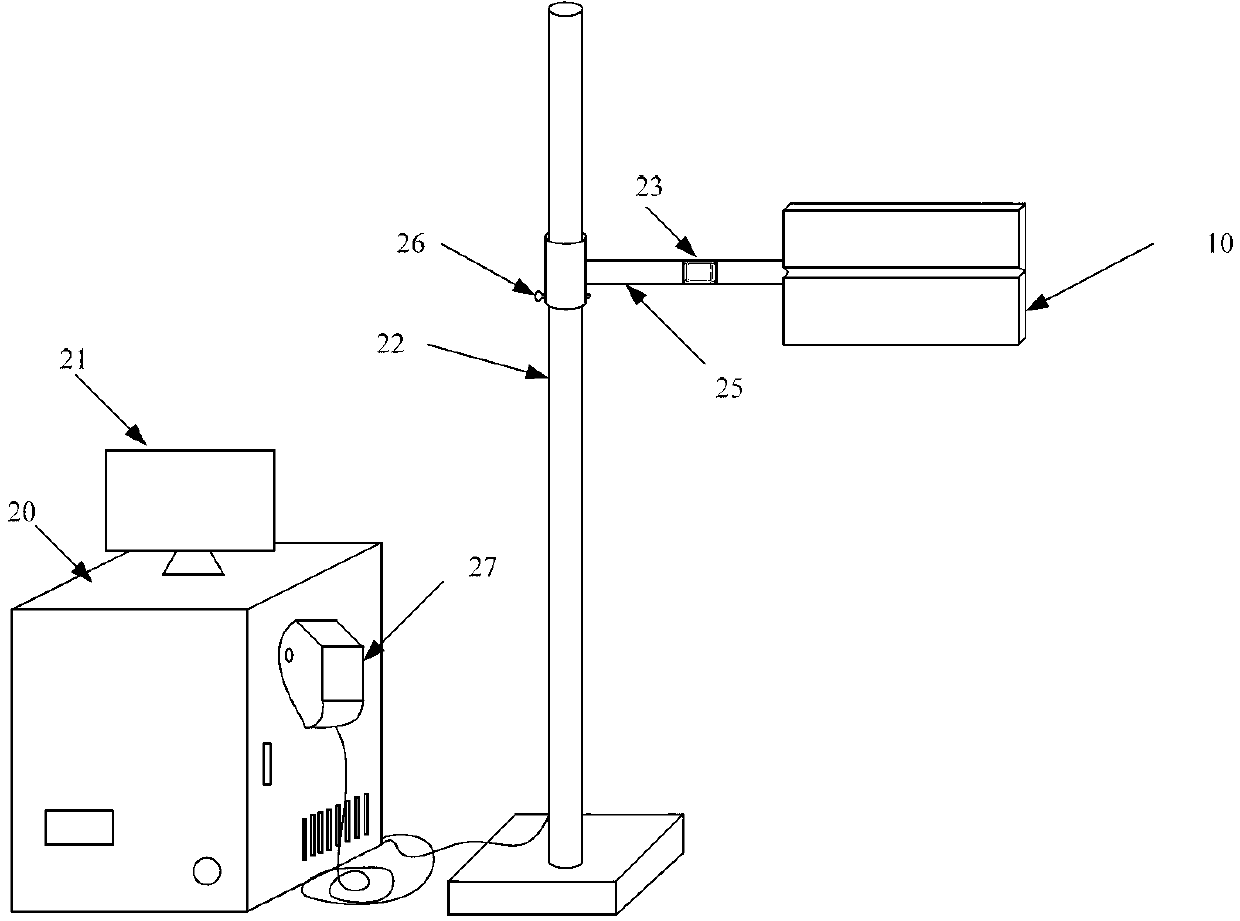

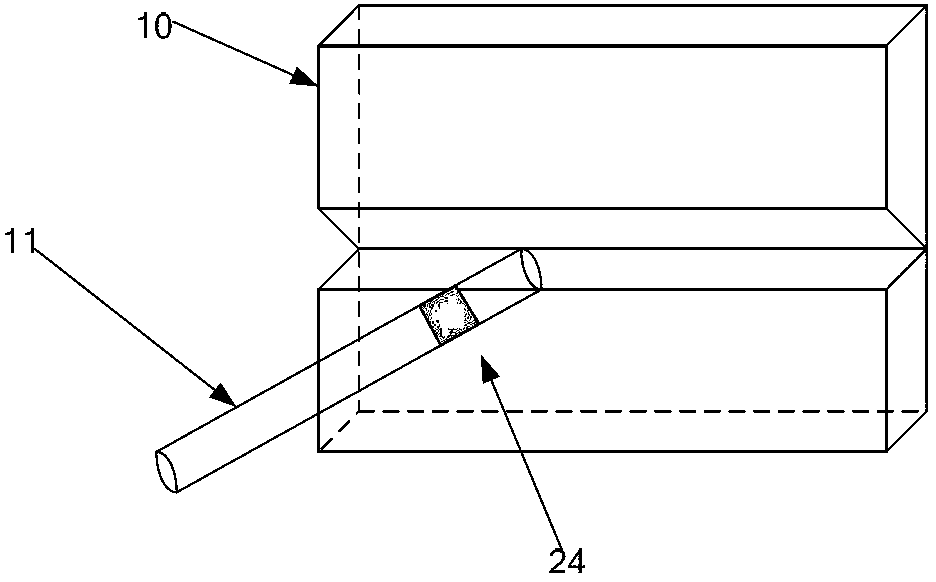

[0055] see figure 1 As shown in Figure 3 (c), the visual horizontal welding position welding operating system of the present invention includes a control cabinet 20, a touch screen display 21, a support frame 22, a simulated test board 10, a simulated welding rod 11 and a simulated helmet 27; the simulated test board 10 is fixed On the adjusting rod 25 , the adjusting rod 25 is fixed on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com