Sideways-pressed ball-point pen

A ballpoint pen and pen holder technology, applied in the field of side pressing ballpoint pens, writing tools, and pressing ballpoint pens, can solve the problems of difficulty in other uses, poor hand feeling, and unsmooth pressing action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, simple and easy side-pressing ballpoint pen

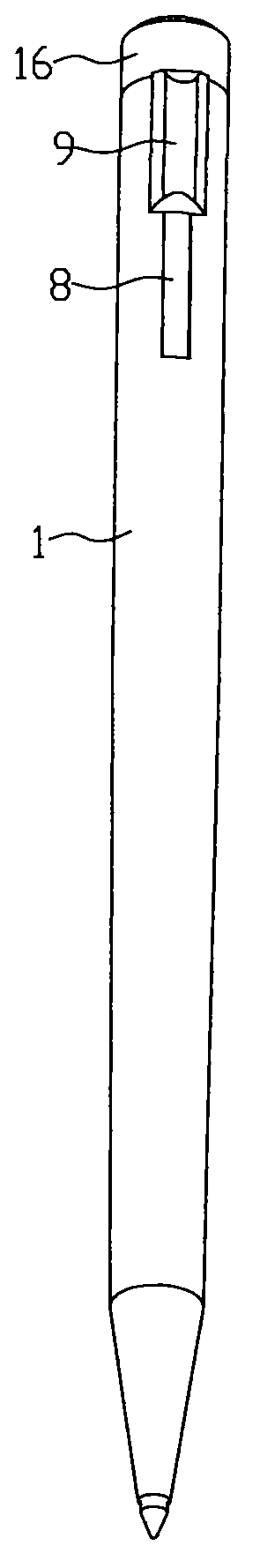

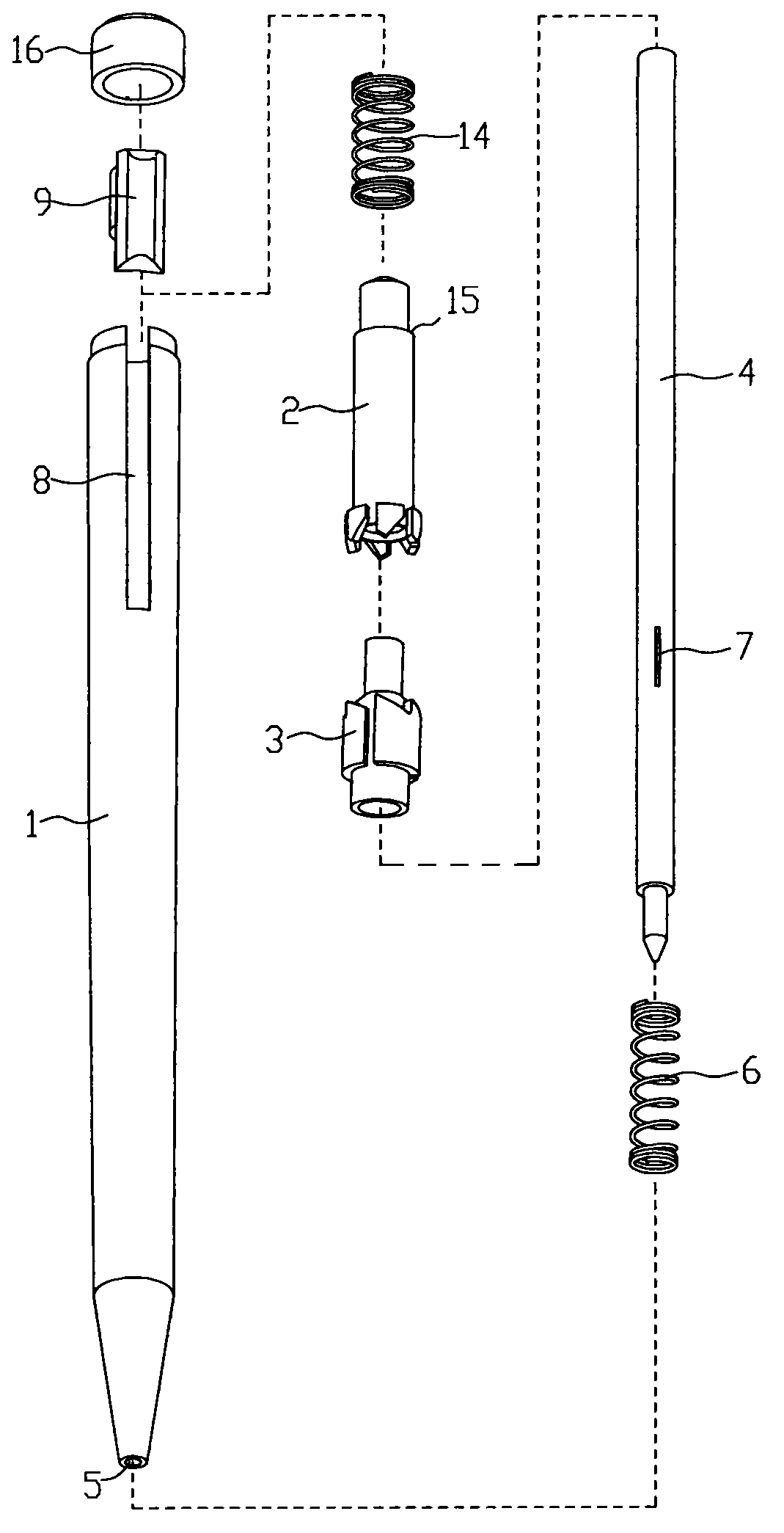

[0034] Such as figure 1 , figure 2 The side-press ballpoint pen shown is the basic embodiment of the present invention. This side pressing ballpoint pen comprises a pen holder 1, a pressing wheel 2, a runner 3, and a refill 4. The pen holder 1 extends along its longitudinal axis between its upper end and its lower end, and its lower end is conical in cross section. The port is provided with a round hole 5 for extending or retracting the nib at the lower end of the pen core, and the pressing wheel 2, the runner 3, and the pen core 4 are located inside the pen holder 1 and connected sequentially from top to bottom, and the inner wall of the pen holder 1 is provided for Press wheel 2, runner 3 to move up and down and control the rib groove of its rotation (this rib groove feature is the prior art, not shown in the figure); The inner wall of the sleeve; the lower part of the refill 4 is set with the lower sprin...

Embodiment 2

[0039] Embodiment 2: A side-pressing ballpoint pen with a touch head

[0040] This embodiment is an embodiment of using the tip of the pen as a touch head for touch input on the electronic touch screen of the present invention. Such as Figure 4 , Figure 5 or Figure 8 , Figure 11As shown, this side-pressing ballpoint pen with a touch head includes a penholder, a pressing wheel 2, a runner 3, and a refill 4. The penholder includes an upper penholder 17 and a lower penholder 18, and a decorative ring 19 is arranged in the middle. The upper penholder 17 and the lower penholder The pen holder 18 is connected with threads, and the lower end of the lower pen holder 18 is a conical shape in which the cross section gradually decreases. The wheel 3 and the pen core 4 are located inside the penholder 1 and are connected sequentially from top to bottom. The inner wall of the penholder 1 is provided with a rib groove for the pressing wheel 2 and the runner 3 to move up and down and...

Embodiment 3

[0047] Embodiment three, have the side-press ball-point pen of erasable rubber block

[0048] This embodiment is the embodiment of the present invention in which an erasable rubber block is set on the top of the pen. The ink contained in the pen core 4 is erasable ink, and the rubber block 27 that can erase the handwriting of this ink is set on the top of the pen holder 17 . Compared with Embodiment 2, this embodiment only replaces the touch head 20 of Embodiment 2 with an erasable rubber block 27 , and the others are completely the same as Embodiment 2, so no detailed description is given here.

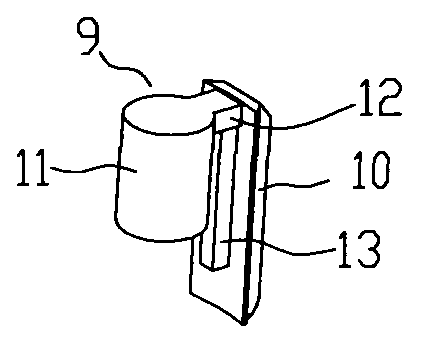

[0049] In addition, as in the second embodiment, the outer part 10 of the actuator 9 is provided with an extension section 25 downwards, which can serve as a pen holder, as Figure 12 or Figure 13 shown; where Figure 12 A schematic diagram of the overall appearance of the pen in which the extension section 25 is provided for the actuator 9 to act as a pen clip; Figure 13 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com