sdl pile driving method and pile drilling rig specially used for carrying out the method

A technology for piling and drilling rigs, which is applied in earthwork drilling, drilling equipment and methods, driving devices for combined rotary drilling, etc. It can solve problems such as idling of drill bits, affecting work efficiency, and limited maximum drilling force of drill bits. The effect of improving drilling force and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

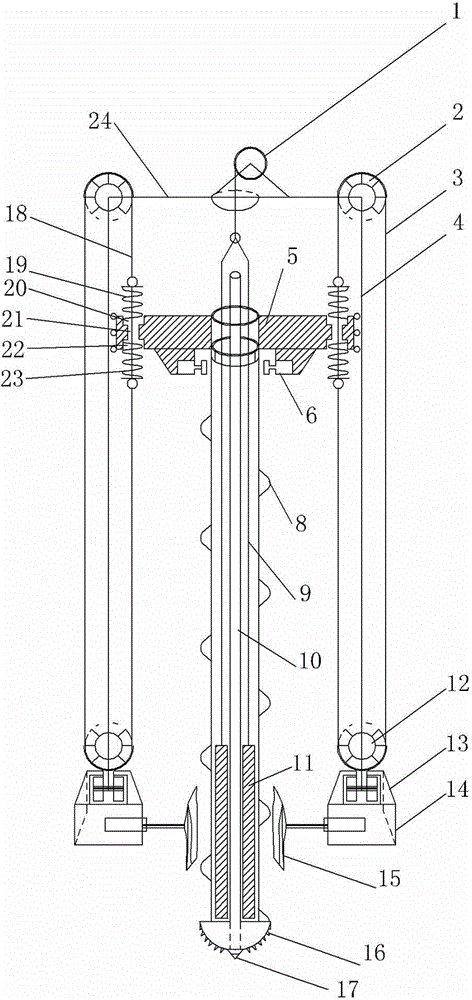

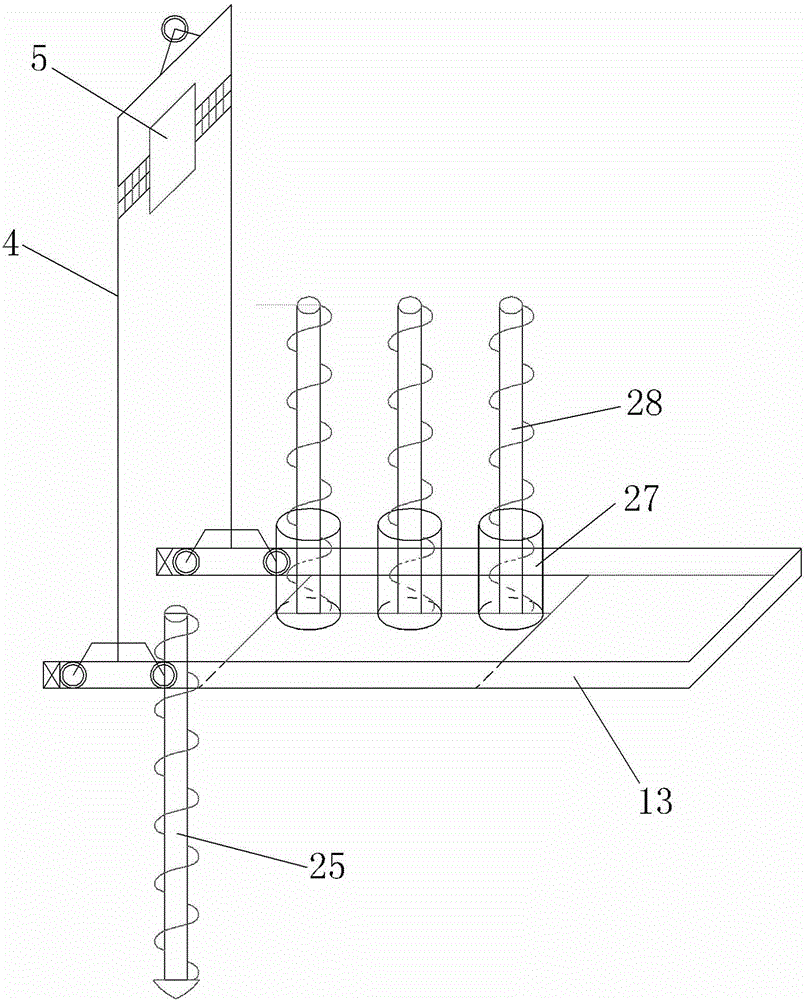

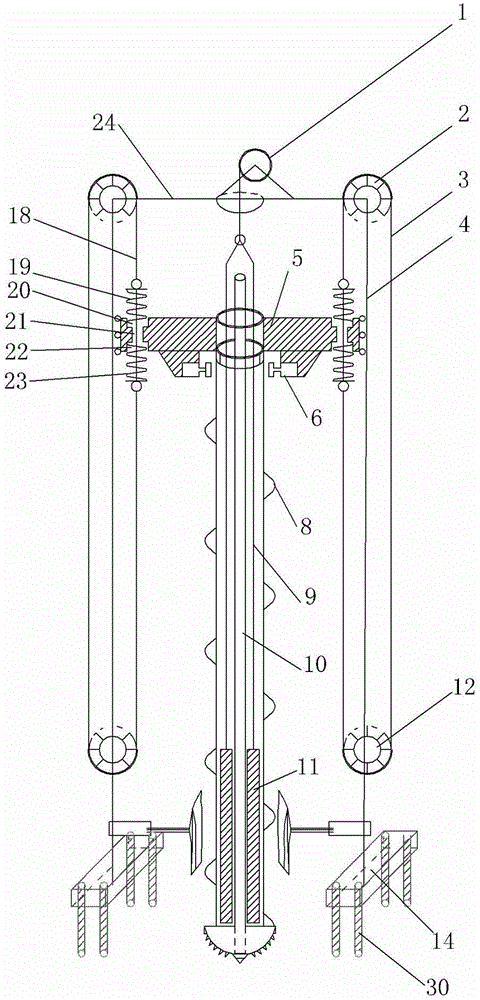

[0020] Example 1 of piling rig Figure 1~2 Shown: including a frame, the frame includes a base 14 and a gantry frame set on the base, the base is provided with a traveling mechanism connection structure for fixed connection with the corresponding traveling mechanism, and the base is assembled on a rotating chassis through the traveling mechanism connection structure On the walking mechanism. The gantry frame includes two uprights 4 and a beam 24 arranged at the top of the two uprights. The two uprights 4 of the gantry frame are equipped with a power head 5 that is guided to move in the up and down direction. The drive head is connected with a spiral on the outer circumference. The working drill rod of the blade 8, a drill bit is installed at the lower end of the working drill rod, a drill tooth 16 is arranged on the drill bit, a feeding pipe 10 is arranged on the inner coaxial line of the working drill rod, and a feed pipe 10 is arranged between the feeding pipe and the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com