Rotary member self-locking device and engineering machinery using same

A technology of rotating components and self-locking devices, which is applied in the direction of lifting devices, pivot connections, etc., can solve the problems of increasing chain size and installation space, irreversible, chain breakage, etc., to avoid chain size and installation space, and improve operation Safety, the effect of preventing accidental tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a self-locking device suitable for rotating components to limit the abnormal rotation of the rotating component relative to the fixed component. Through the cooperation of the components of the self-locking device, the unsafe hidden danger caused by the failure of rotation control can be completely avoided . The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0030] Without loss of generality, this embodiment takes the working bucket and the jib of the aerial work vehicle as the connection objects for detailed description. It should be understood that the specific connection method between the working bucket and the jib does not limit the protection scope of the present application.

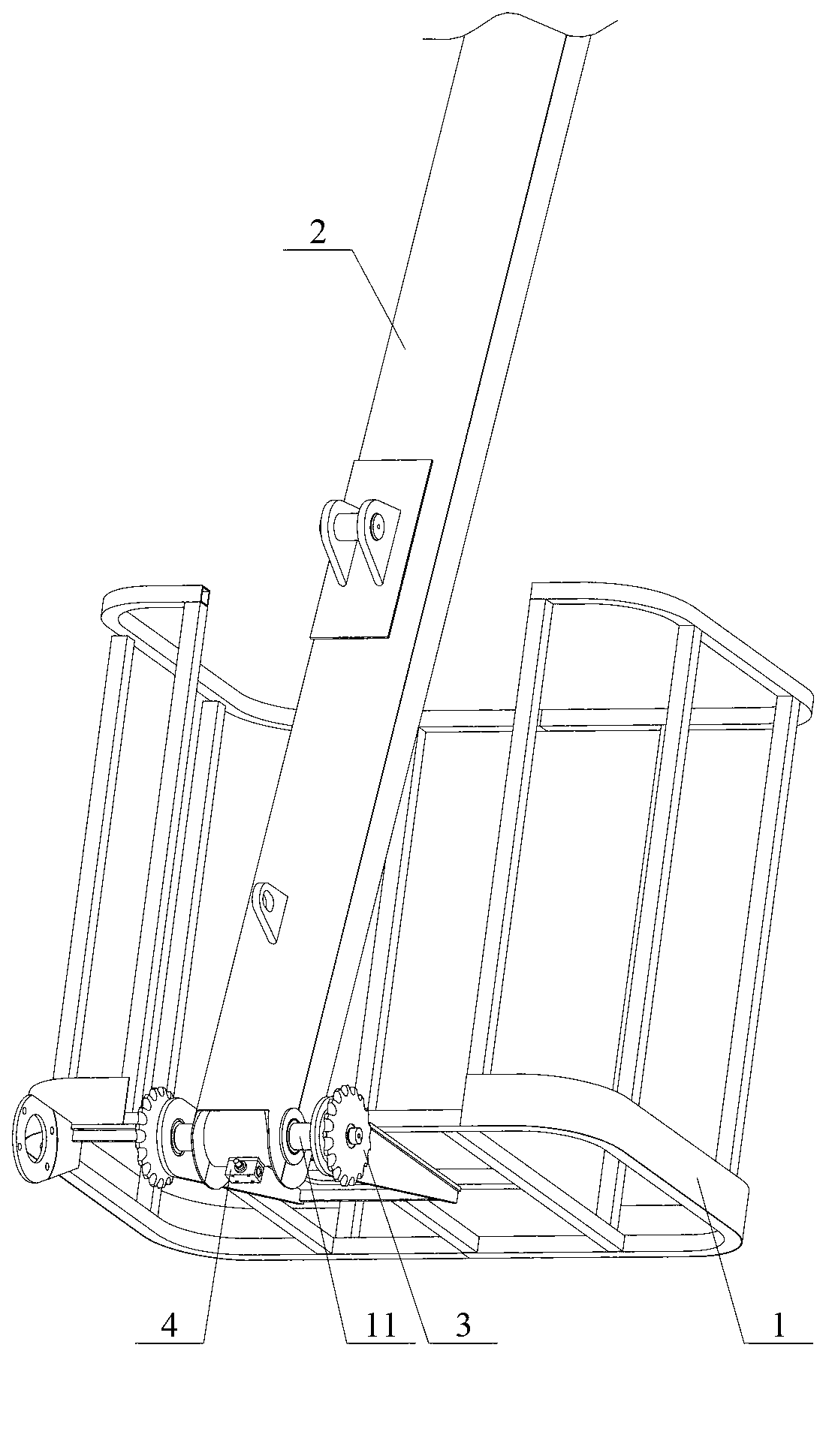

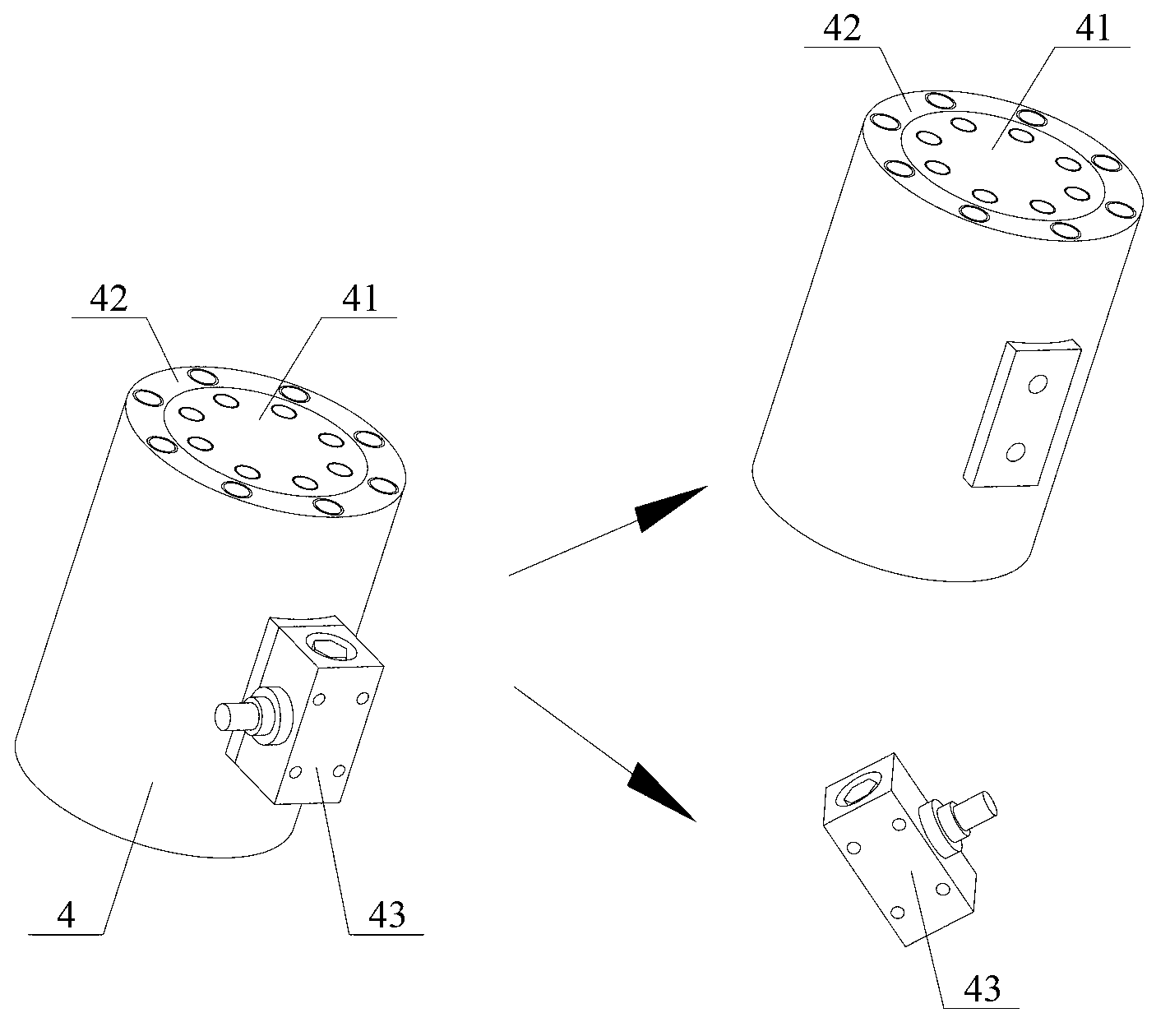

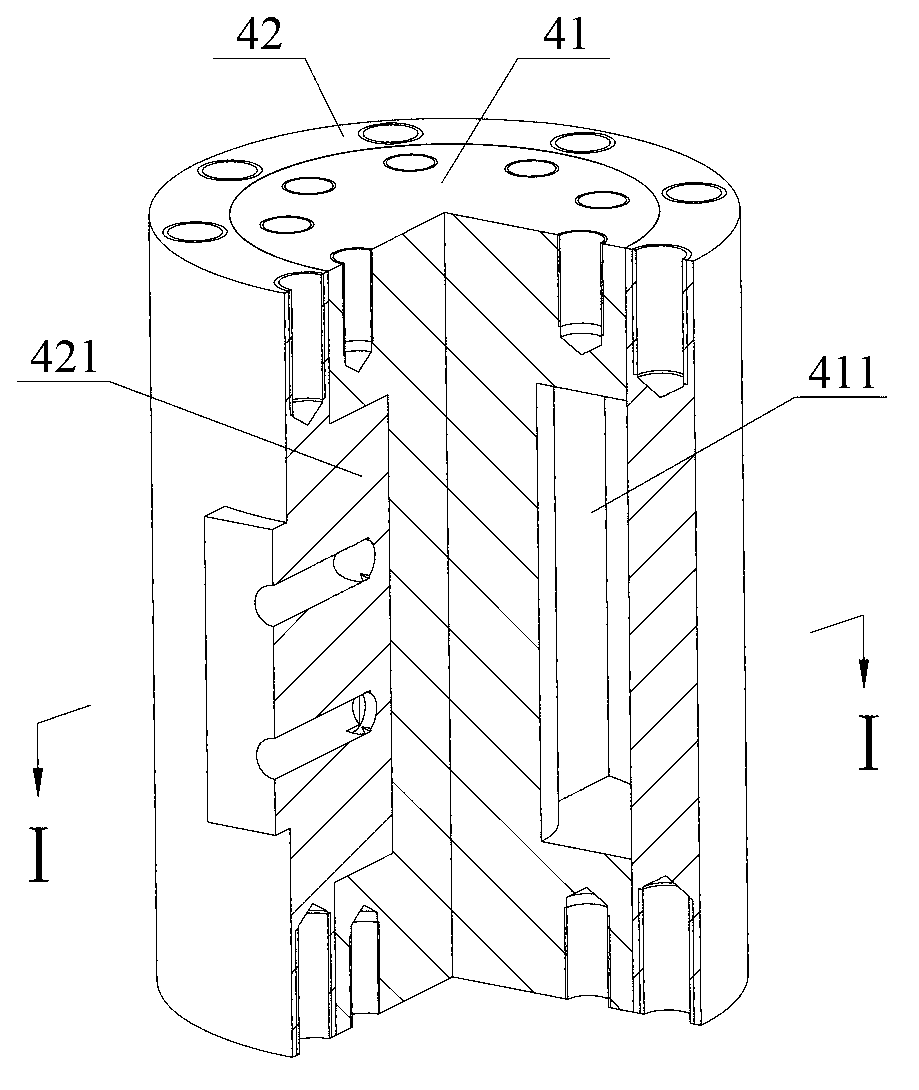

[0031] Please also see figure 1 and figure 2 ,in, figure 1 A schematic diagram showing the installation position of the rotating member self-locking device according to this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com