Discharging gap device

A discharge gap and installation slot technology, applied in the direction of circuits, electrical components, insulators, etc., can solve the problems of arc easy to burn insulators, unstable discharge voltage, low cost of arc ignition angle, etc., and achieve good arc resistance and arc extinguishing performance, discharge The effect of voltage stability, suppression of vibration and galloping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

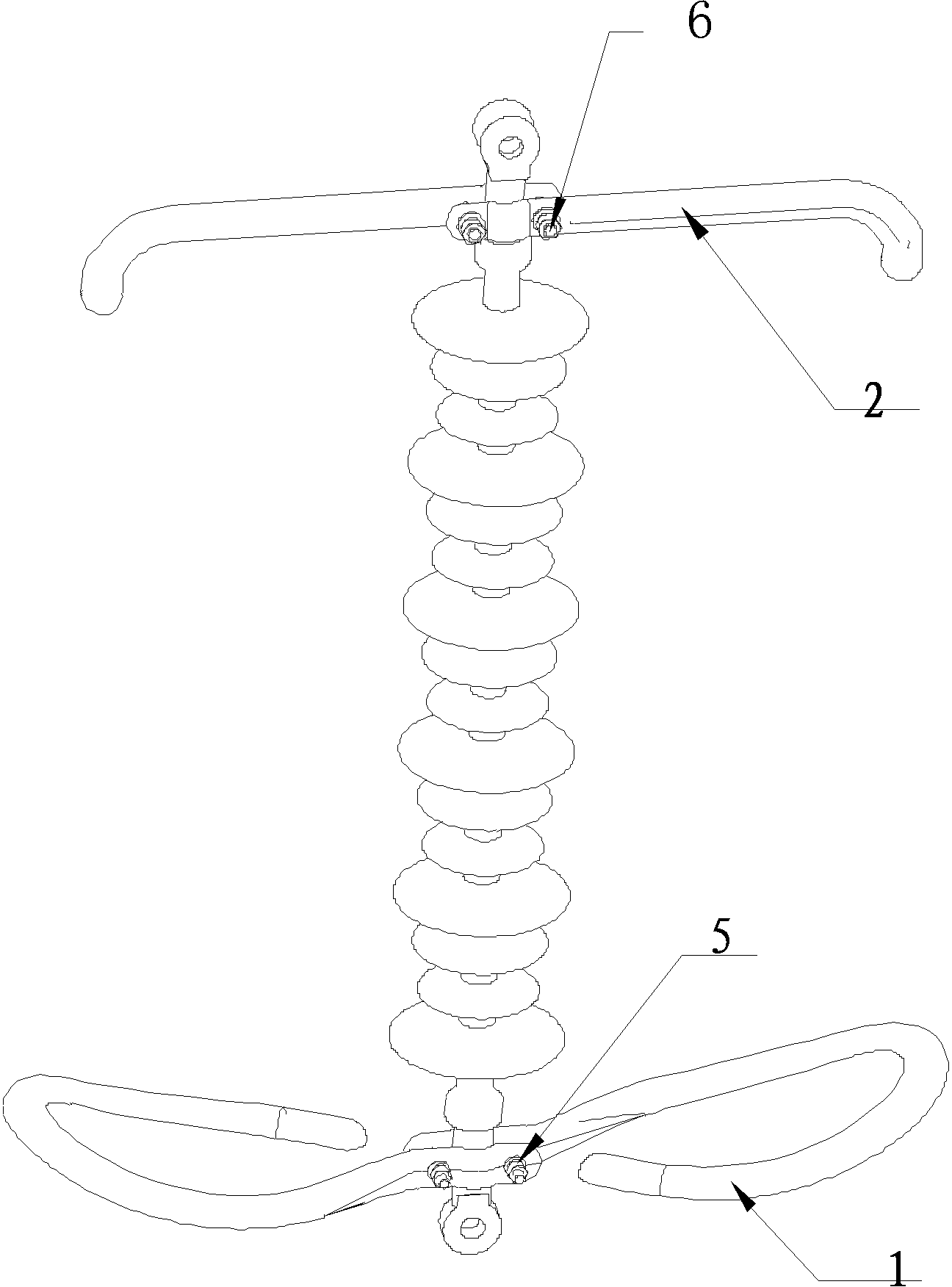

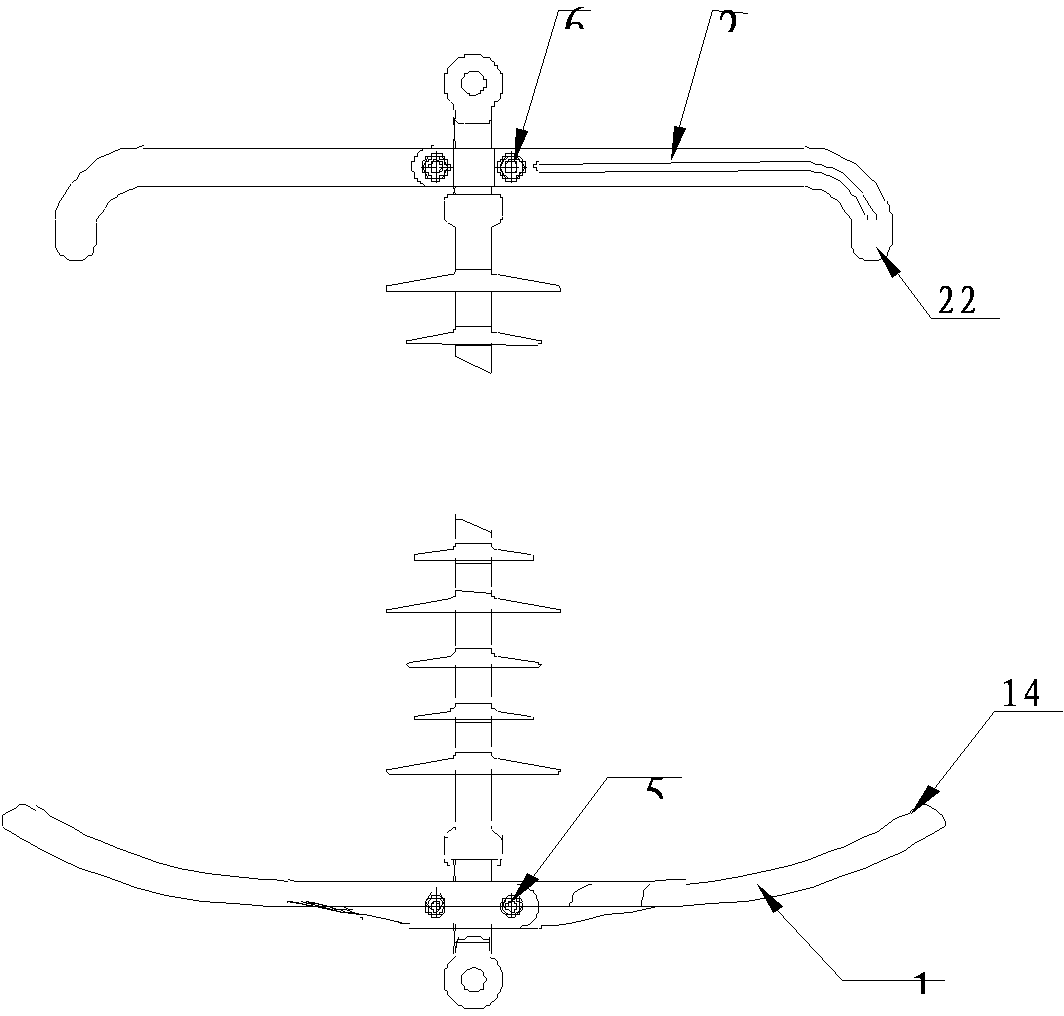

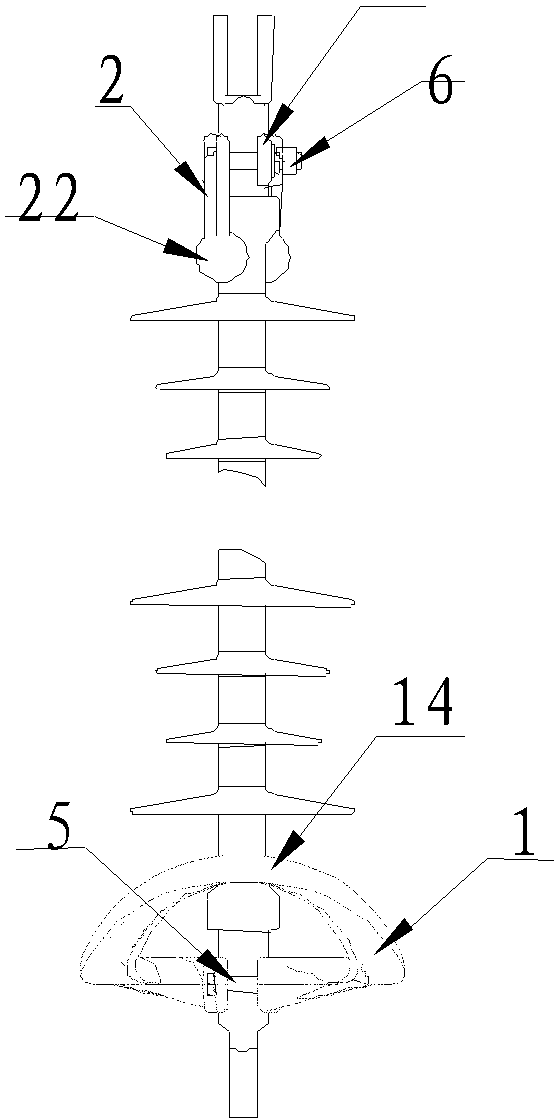

[0027] The present invention is a discharge gap device, such as Figure 1-Figure 4 As shown, the present invention is mainly composed of a high-voltage arc striking ring 1 , an arc striking angle 2 , a first fastener 5 and a second fastener 6 . It is symmetrically connected up and down on the two ends of the composite insulator by the high voltage arc striking ring 1 and the arc striking angle 2 . There are two high-voltage arc strike rings 1 symmetrically, connected by a first fastener 5 . There are two symmetrical arc striking angles 2 connected by second fasteners 6 .

[0028] Such as Figure 5 as shown, Figure 5 It is a schematic diagram of the structure of the medium and high voltage arc starting ring of the present invention. The shape of the high voltage arc starting ring 1 of the present invention is an open ellipse, one end of the opening is a mounting handle 11, and the other end of the oval shape of the high voltage arc starting ring 1 is a slightly upwardly cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com