Buzzer drive circuit

A technology for driving circuits and buzzers, applied in transducer circuits, sensors, electrical components, etc., can solve the problems affecting the sound quality and volume of the buzzer, the voltage bias of the buzzer, and the bulky volume, and achieve good sound quality. , Avoid DC voltage bias, the effect of small installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

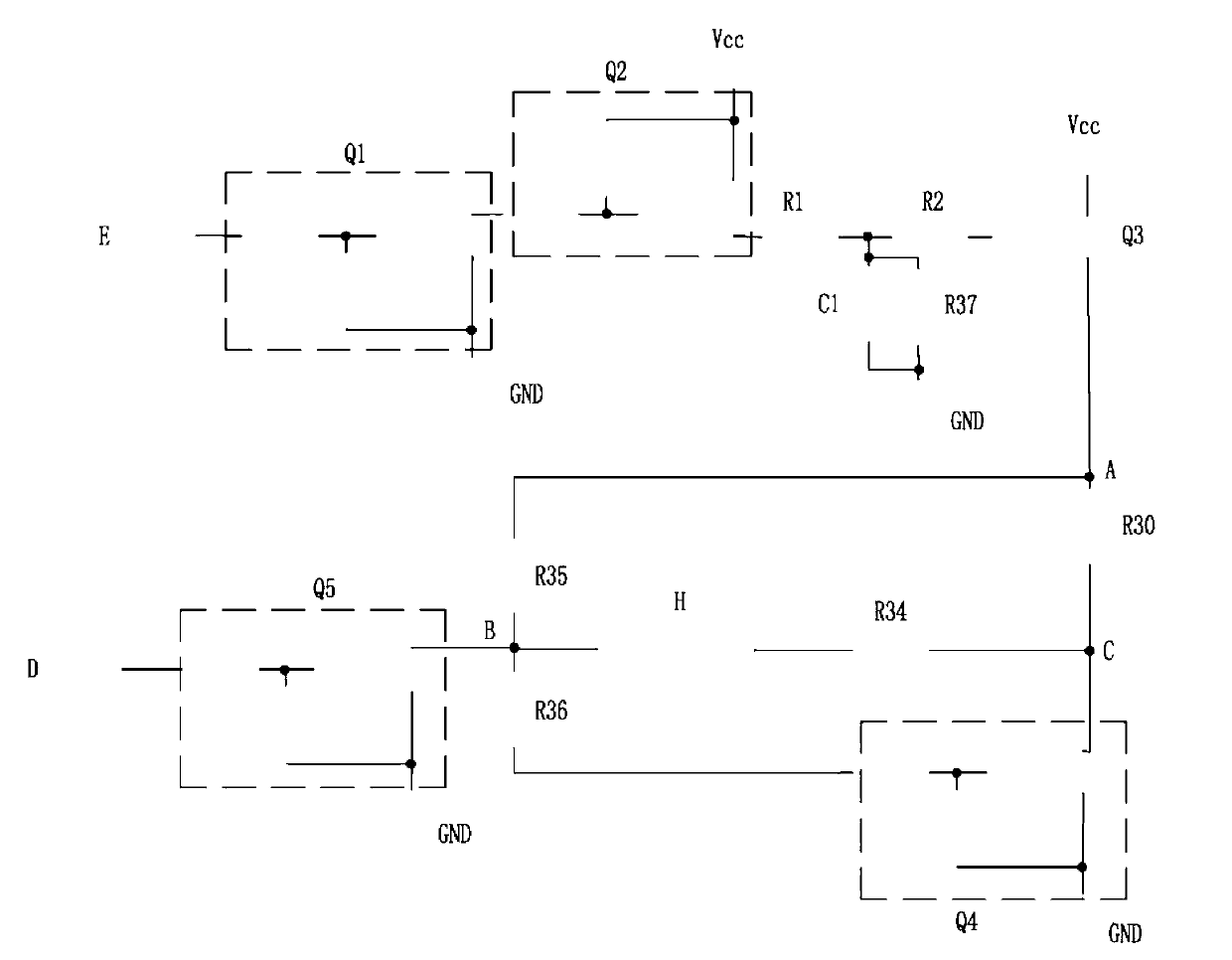

[0024] Such as figure 1 , 2 The buzzer drive circuit shown includes an electrically connected power supply module and a control module, and the control module is connected to the buzzer H to drive the buzzer H, wherein: the control module is DC The pulse-to-AC conversion control module makes the driving voltage at both ends of the buzzer H become an AC voltage with the same control frequency and alternating directions, so that the buzzer of the buzzer H vibrates back and forth in two directions;

[0025] The DC pulse-to-AC conversion control module includes a DC pulse signal output terminal D, a fifth transistor Q5, and a fourth transistor Q4. The DC pulse signal output terminal D outputs a DC pulse signal with a certain period, so The fifth triode Q5 and the fourth triode Q4 described above respectively realize their own periodic conduction / cutoff or cutoff / conduction actions under the action of the DC pulse signal, and then realize the driving voltage at both ends of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com