Multi-stage supercharging device

A technology of supercharging device and supercharger, which is applied in gas turbine device, charging system, internal combustion piston engine, etc., can solve the problem that the flow resistance of the exhaust flow path increases, the sealing performance decreases, and the pressure loss of the exhaust gas flow increases, etc. problems, to achieve the effect of improving the supercharging efficiency and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

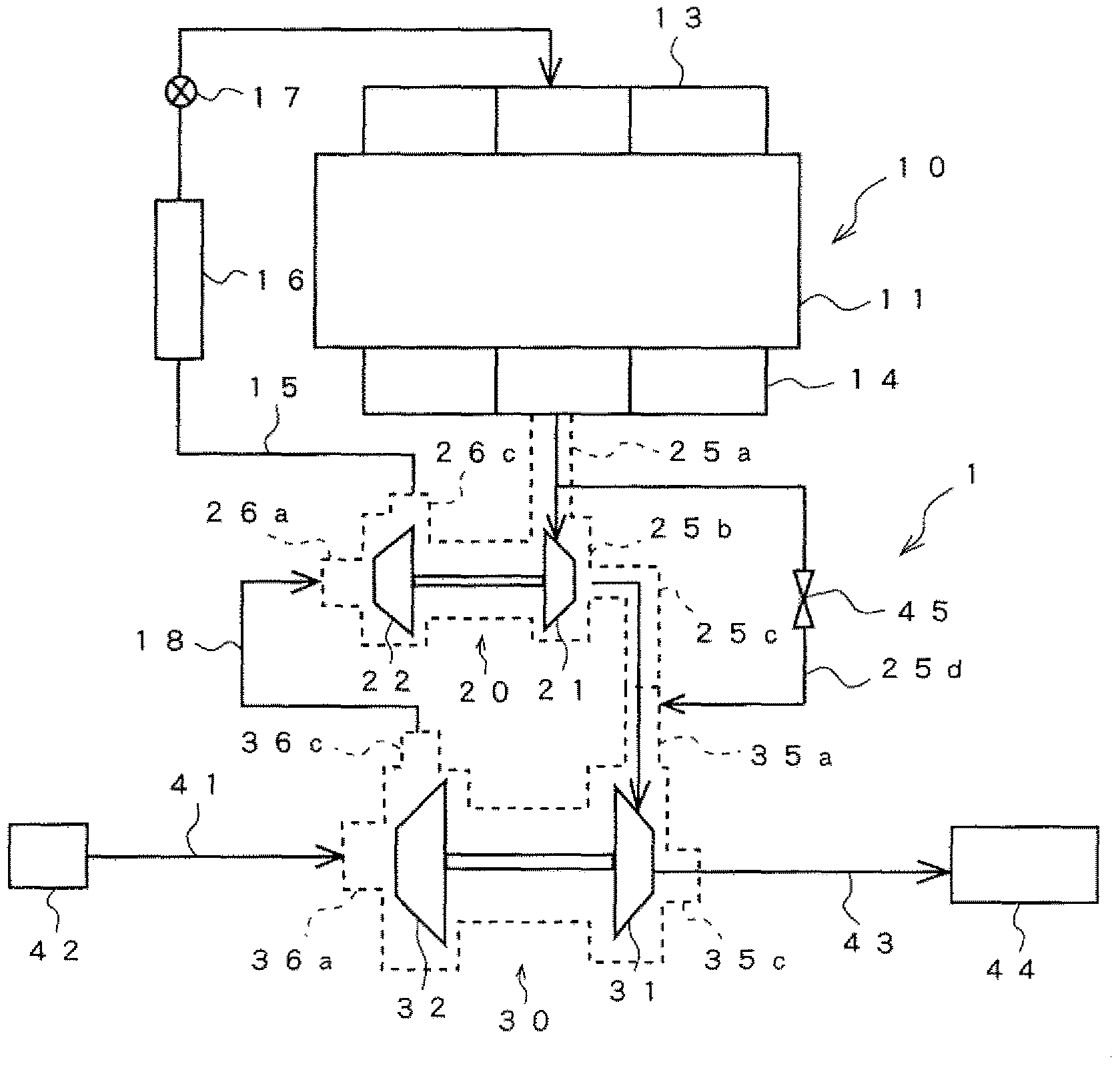

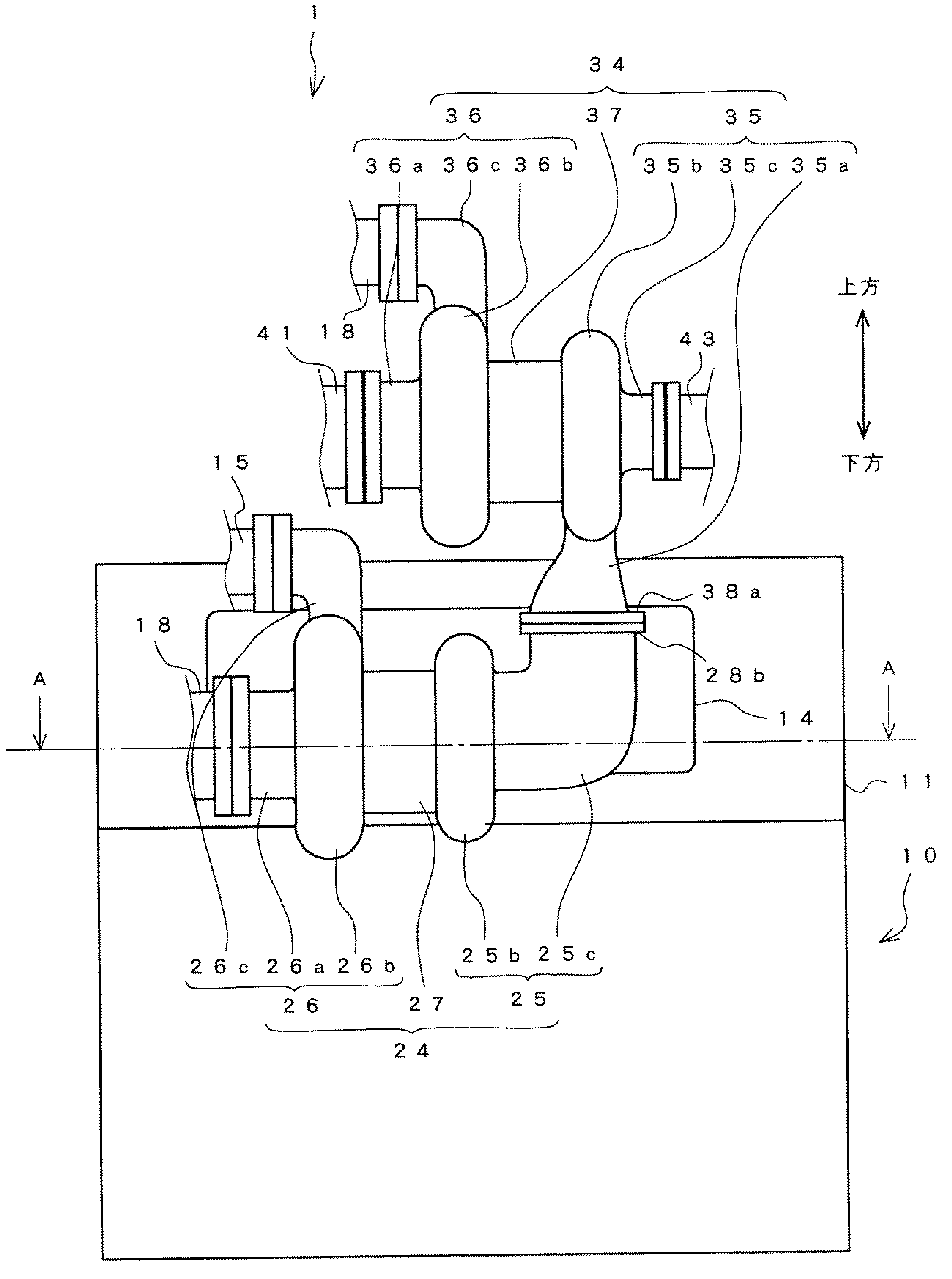

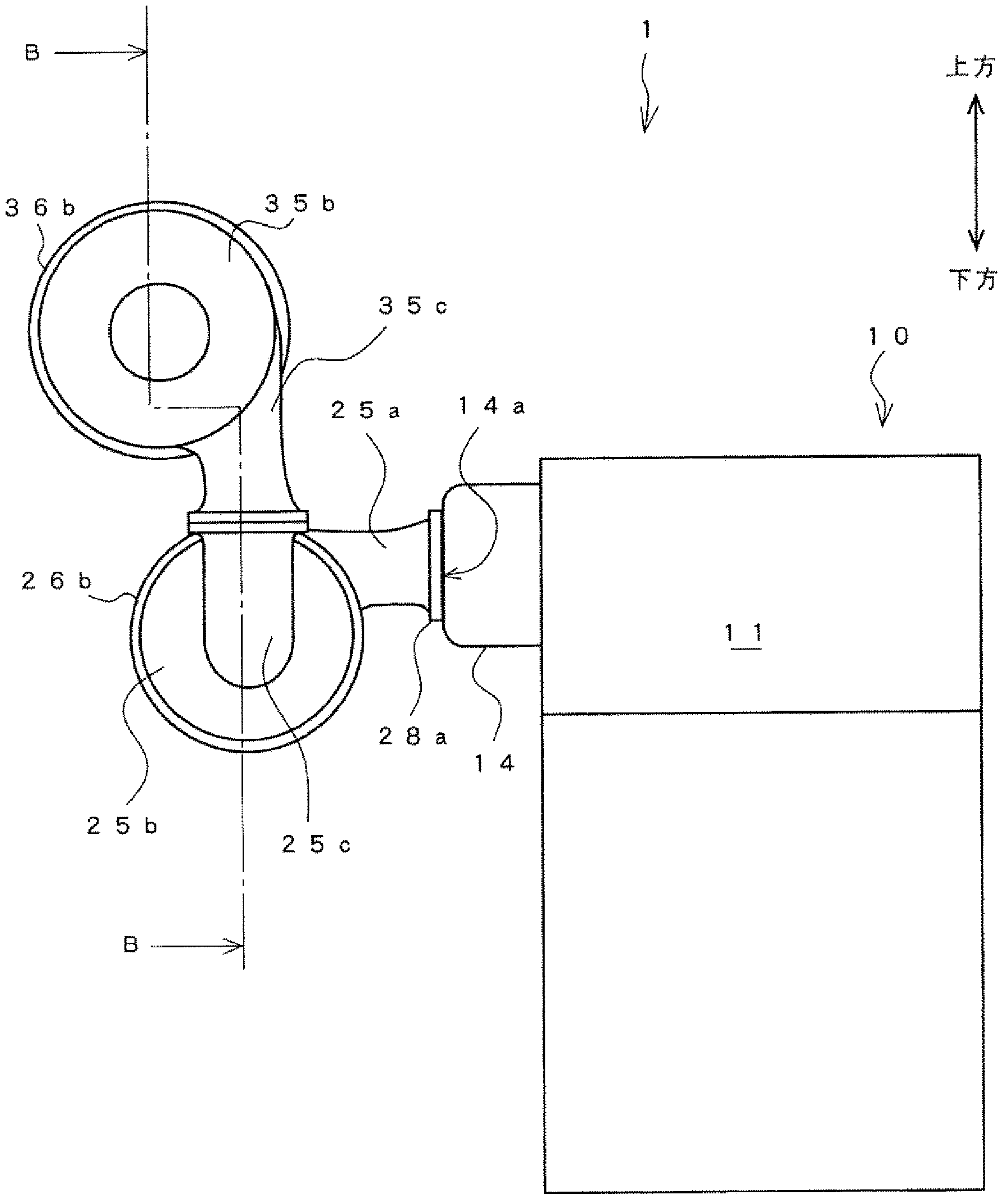

[0024] Below, according to Figure 1~5 A multistage booster device according to one embodiment of the present invention will be described. The same reference numerals are assigned to the same components, and their names and functions are also the same. Therefore, detailed description thereof will not be repeated.

[0025] A multi-stage supercharging device 1 according to an embodiment of the present invention is as figure 1 As shown, a diesel engine (hereinafter simply referred to as an engine) 10 mounted on a vehicle is provided in parallel, and has a high-pressure stage turbocharger 20 and a low-pressure stage turbocharger 30 having a larger capacity than the high-pressure stage turbocharger 20 . In addition, the high-pressure-stage turbocharger 20 of the present embodiment corresponds to the first supercharger of the present invention. In addition, the low-pressure stage turbocharger 30 of the present embodiment corresponds to the second supercharger of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com